System for automatically extinguishing fire in long tunnel and extinguishing method thereof

An automatic fire extinguishing system and tunnel technology, applied in earthwork drilling, fire prevention, safety devices, etc., can solve the problems of high cost of gas fire extinguishing system, difficulty in controlling fire with fire hydrants, environmental and human hazards, etc., and achieve specific surface area and density High, good fire extinguishing effect, the effect of preventing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

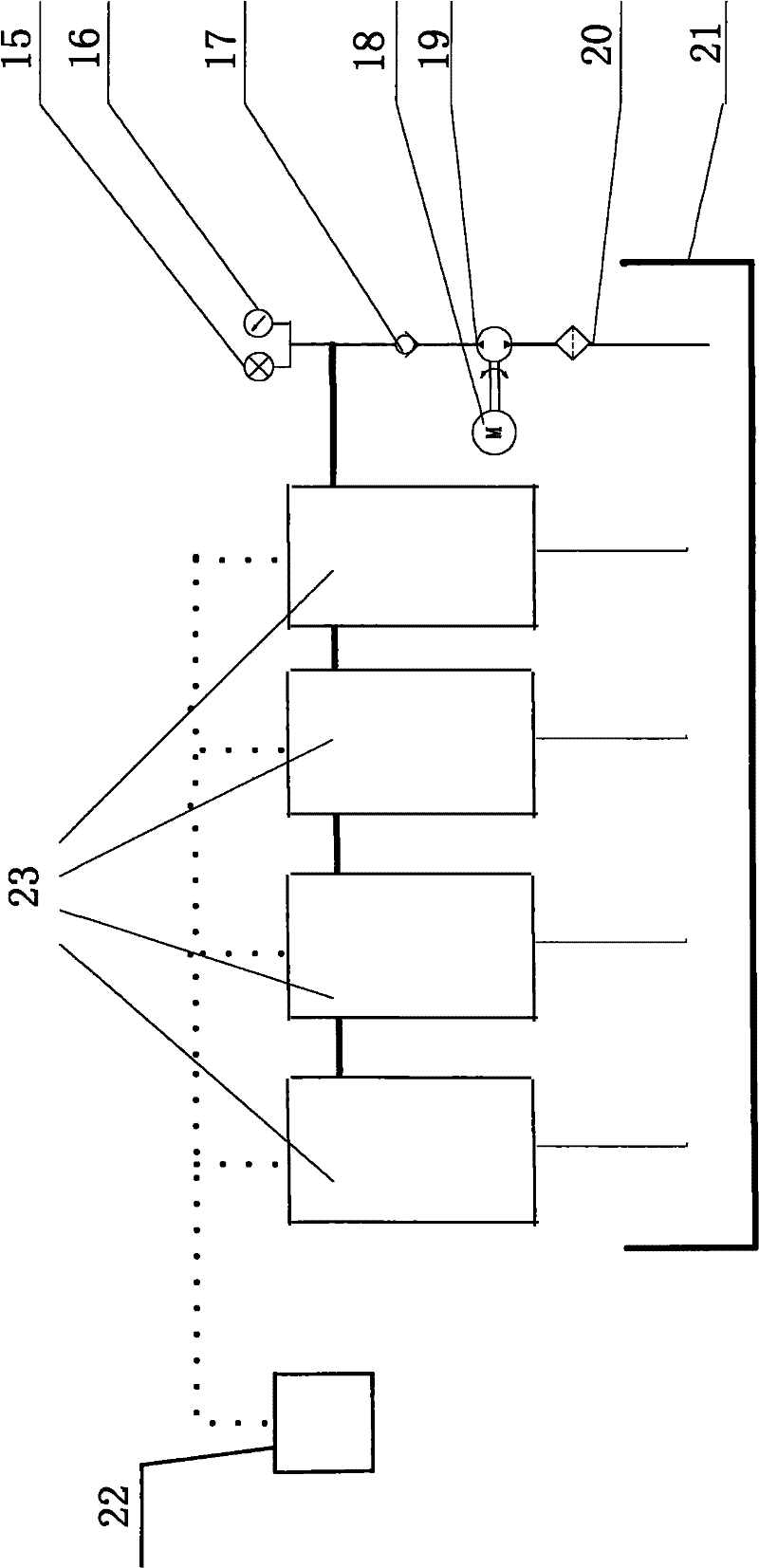

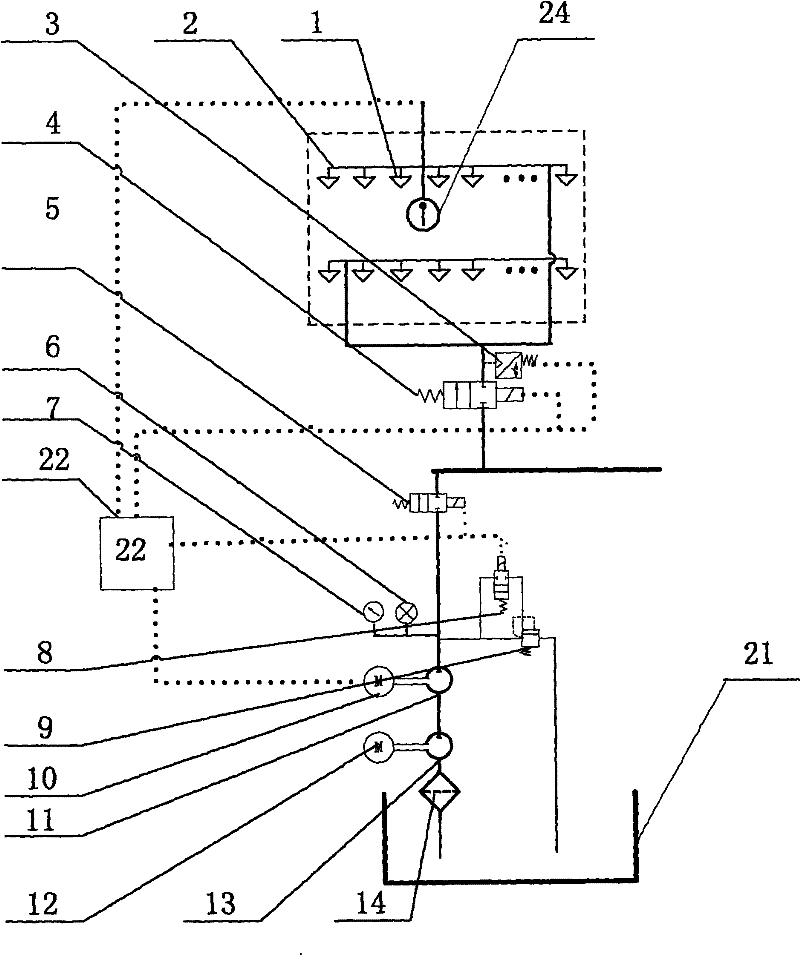

[0025] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-2 As shown, a long tunnel automatic fire extinguishing system includes an emergency pressure transmitter 15, an emergency pressure gauge 16, an emergency one-way valve 17, an emergency motor 18, an emergency pump 19, an emergency filter 20, a water tank 21, a PLC controller 22 and three More than one single-zone fire extinguishing unit 23, one end of the emergency filter 20 is connected to the water tank 21 through a pipeline, and the other end is connected to the emergency pump 19 through a pipeline, and the emergency motor 18 is connected to the emergency pump 19. The emergency pressure transmitter 15 and the emergency pressure gauge 16 are all installed on the high-pressure pipe at the water outlet of the emergency pump 19, and the emergency pump 19 is respectively connected to each single-zone fire extinguishing unit 23 through the high-pressure pipe, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com