Efficient extraction method of friction fault characteristics in vibration signal of rotating shaft

A technology of fault characteristics and extraction methods, applied in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems that cannot be applied to engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

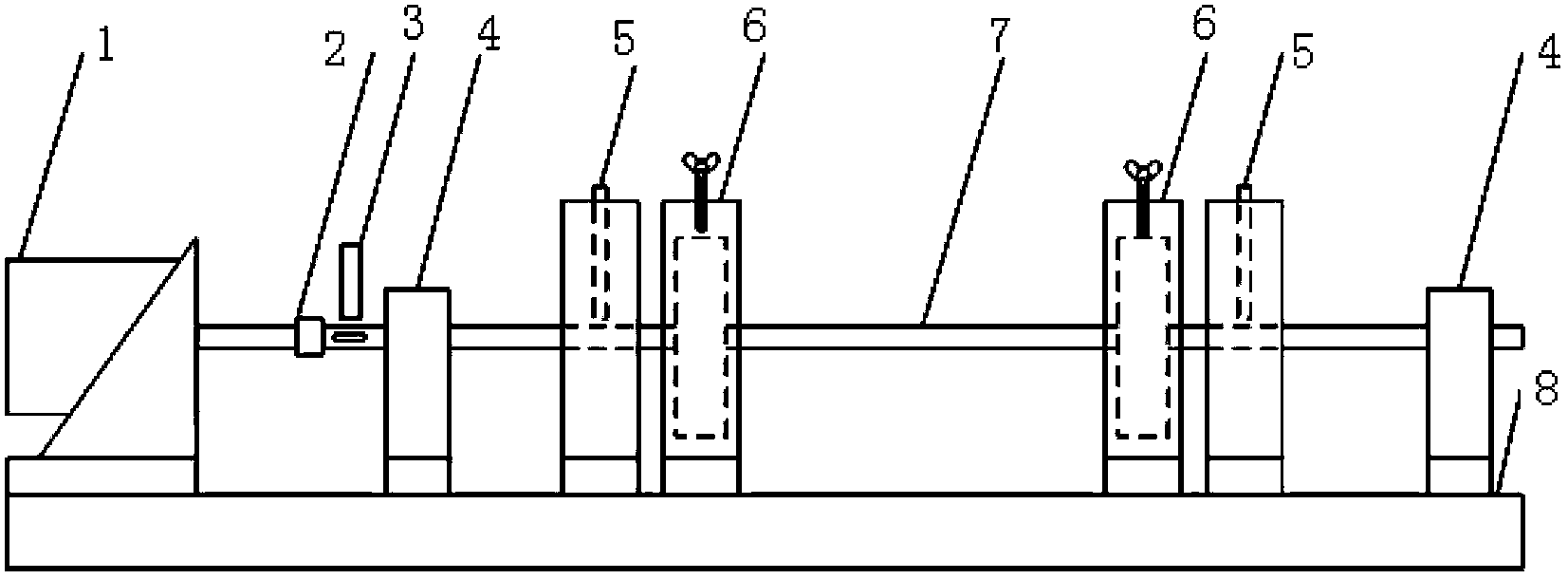

[0046] This embodiment is based on figure 1 Taking the rotor test rig shown as an example, the analysis of the efficient extraction method for early friction faults is carried out.

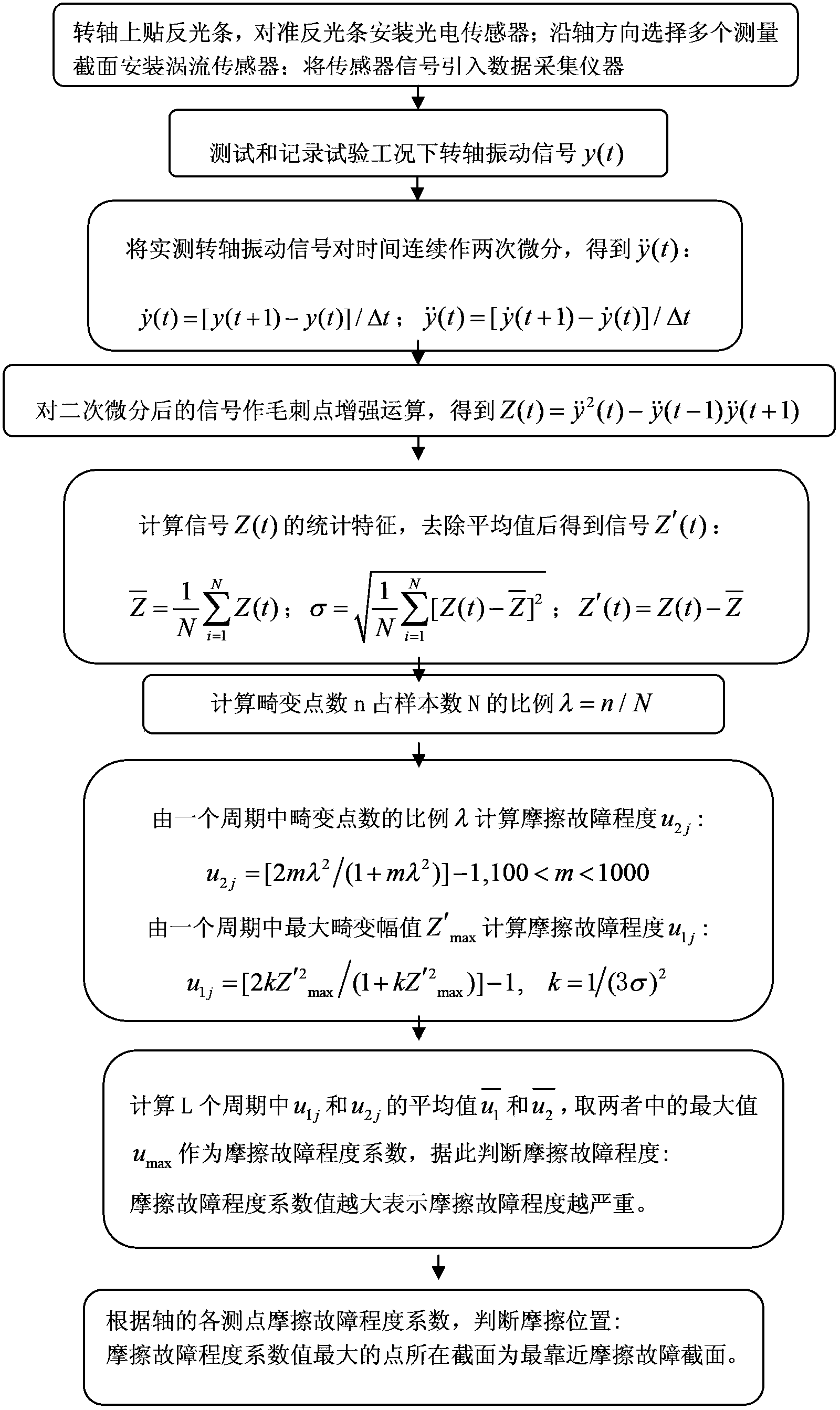

[0047] The efficient extraction and analysis method for the friction fault of the rotating shaft involved in this embodiment is:

[0048] (1) Paste a reflective strip on the exposed shaft section, align the photoelectric sensor with the reflective strip, and measure the speed pulse signal, which is used as a benchmark for synchronous whole-period sampling and analysis of multiple measuring points.

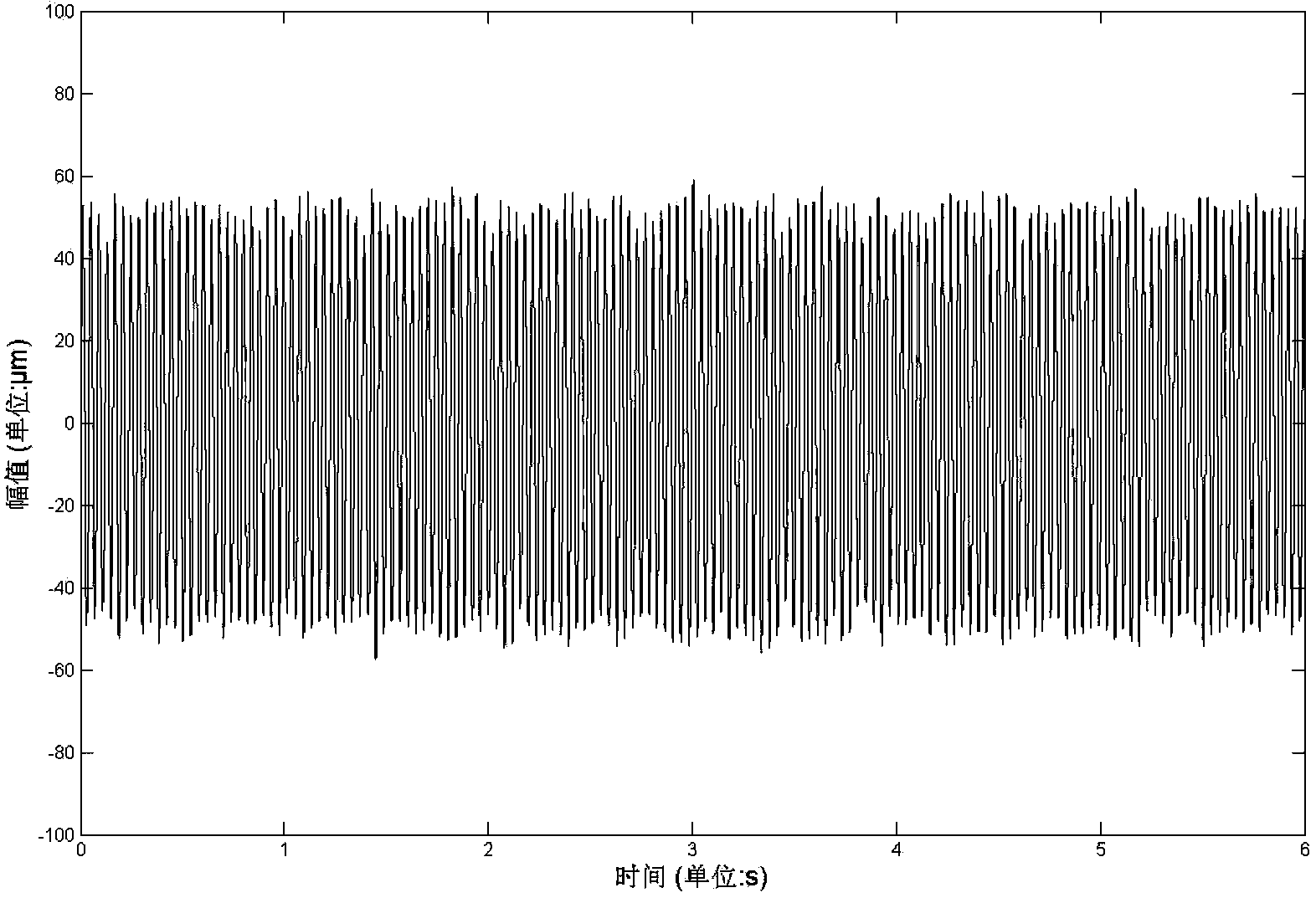

[0049] (2) Arrange non-contact eddy current sensors with a sensitivity of 7.87mV / μm at different sections of the rotating shaft to monitor the vibration signal y(t) of the rotating shaft. (3) Set signal acquisition and analysis parameters:

[0050] Analysis frequency f a =20KHz

[0051] Acquisition frequency f s =5.12KHz

[0052] Sampling cycle number L=20

[0053] (4) Perform a differential ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com