Shell and manufacturing method thereof

A manufacturing method and shell technology, which can be used in electrical equipment shells/cabinets/drawers, patterns imitating natural patterns, decorative arts, etc., which can solve the problems of lack of three-dimensional sense and lack of metal texture in patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

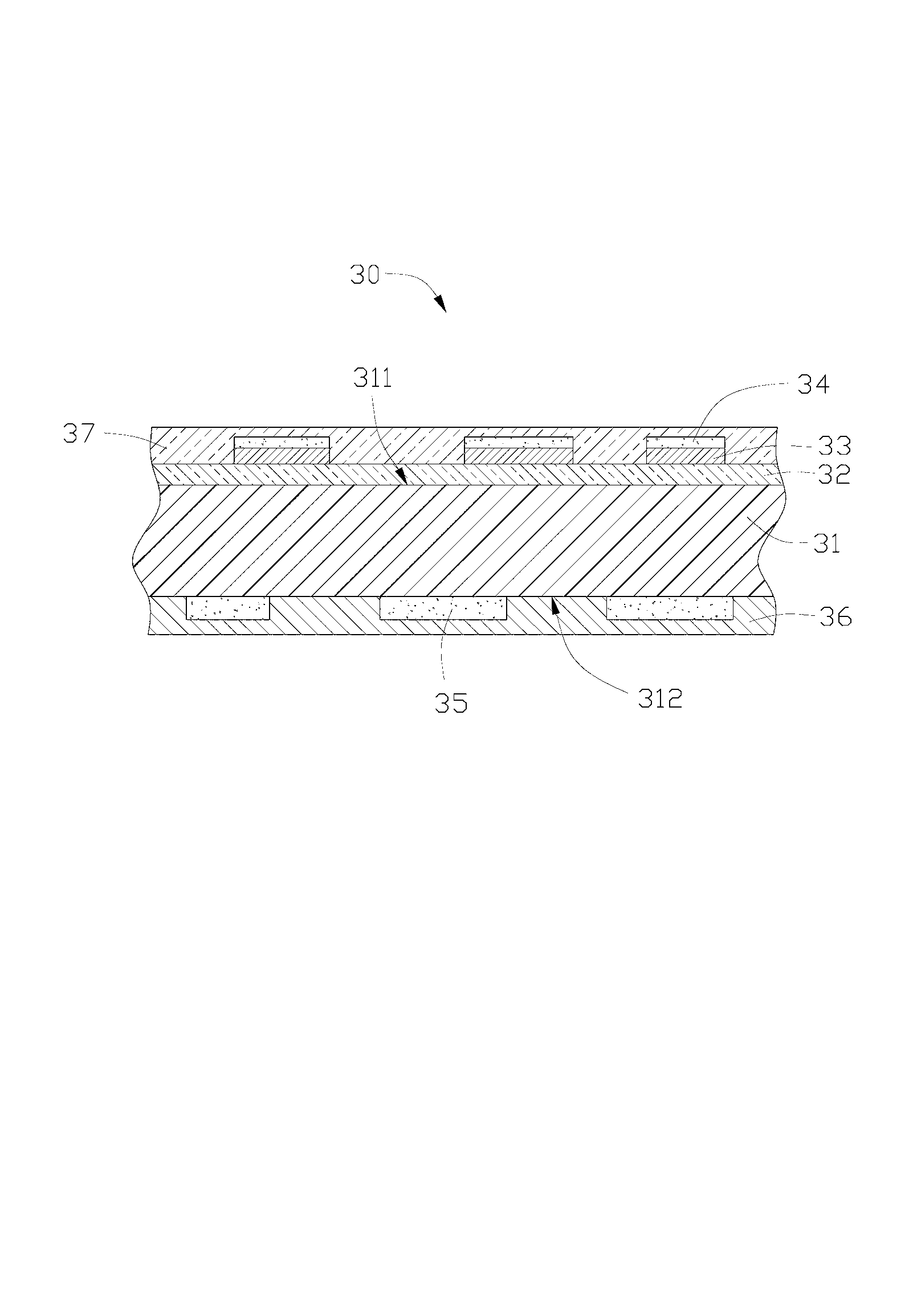

[0020] see figure 1 , the shell 30 of the preferred embodiment of the present invention comprises a transparent substrate 31, a primer layer 32, a first vacuum coating layer 33, a first pattern layer 34, a second pattern layer 35, a second vacuum coating layer 36 and a protective layer 37.

[0021] The base 31 is made of transparent plastic, such as (Poly Carbonate, PC) engineering plastic, polymethyl methacrylate (Polymethyl Methacrylate, PMMA) and the like. The base body 31 can also be made of transparent glass. The base body 31 includes an outer surface 311 and an inner surface 312 opposite to the outer surface 311 .

[0022] The primer layer 32 is directly formed on the outer surface 311 of the substrate 31 . The primer layer 32 is formed of transparent paint. The primer layer 32 is used to improve the adhesion of the first vacuum coating layer 33 .

[0023] The first vacuum coating layer 33 is directly formed on the primer layer 32 and partially covers the primer lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com