Middle sealing mechanism for cylindrical forming of non-woven fabric

A non-woven fabric and tube-shaped technology, which is applied in the field of non-woven fabric tube-shaped sealing mechanism, can solve the problems of wrinkling, non-woven fabric deviation, poor appearance quality, etc., and achieve the effect of highlighting the substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

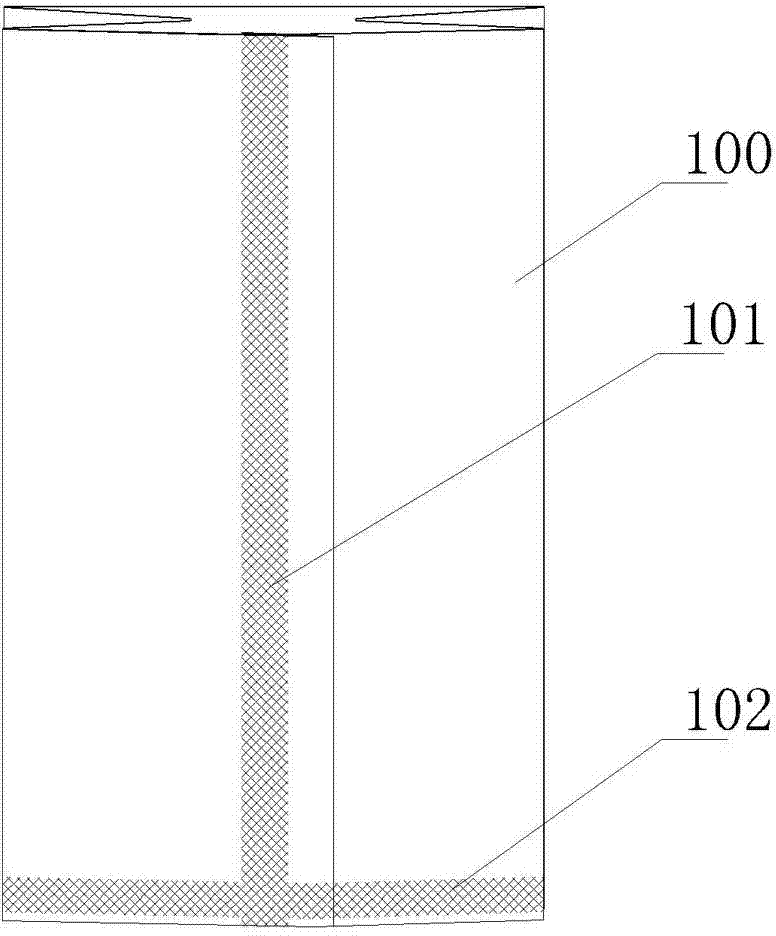

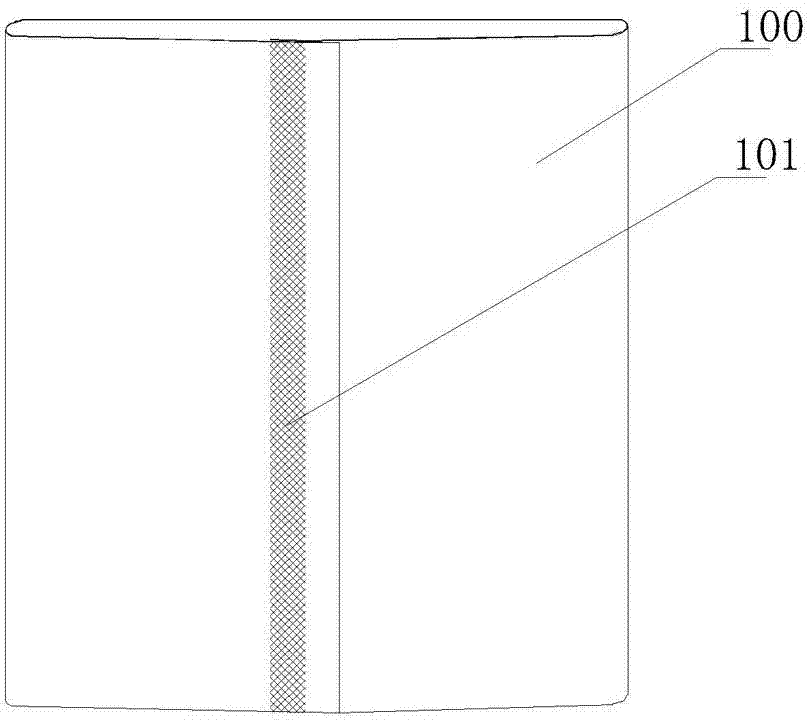

[0019] figure 1 As shown, the anti-blocking bag for washing funnel is made of thin non-woven sheet material 100, and its shape is square, with a middle sealing line 101 and a bottom sealing line 102, and M-shaped inserts on both sides. figure 2 Shown is the outline drawing of the non-woven fabric sheet 100 just after the single-sided center seal is completed, the center seal line 101, and the non-woven fabric sheet 100 becomes a cylinder after the single-side center seal is completed, and the inner circumference of the cylinder is Type non-woven tubular molding size.

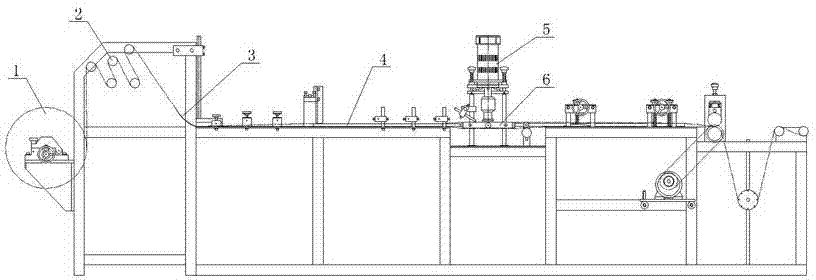

[0020] image 3 , 4 Shown is a fully automatic non-woven bag-making machine for the production of anti-blocking bags for scrubbing funnels, including an unwinding frame 1, a set of guide rollers 2, a turning mechanism 3 and a non-woven tubular forming center sealing mechanism.

[0021] Figure 5 , 6 As shown, the non-woven fabric tubular forming middle sealing mechanism of the present invention comprises a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com