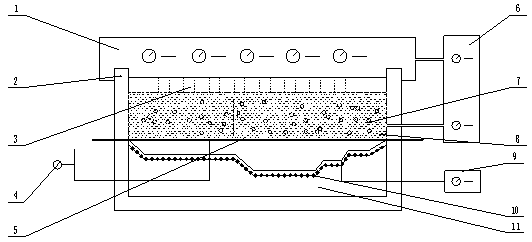

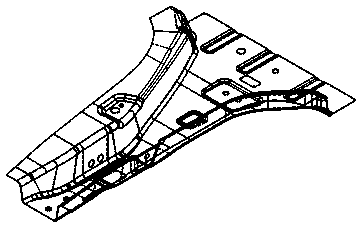

Rapid forming method and device of martensitic steel composite structure

A martensitic steel and composite structure technology, used in transportation, packaging, vehicle parts, etc., can solve the problems of low forming temperature and poor formability, and achieve the effects of improving formability, fatigue performance, and forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A rapid liquid-filled forming method for a martensitic steel composite plate structure, comprising the following steps:

[0039] 1) Surface treatment of martensitic steel: Use acetone to clean and degrease the surface of 0.5mm thick martensitic steel, and use phosphating solution for phosphating treatment after sandblasting. The formula of the phosphating solution used is: zinc oxide 12 g / L, sodium nitrate 4 g / L, surfactant OP-10 emulsifier 5 g / L, surfactant sodium dodecylbenzene sulfonate 5 g / L, hydrogen Sodium oxide and phosphoric acid adjust the pH to 2~4. The phosphating process is carried out at 25°C, the water temperature of the phosphating solution is 26°C, and the phosphating time is 10 minutes.

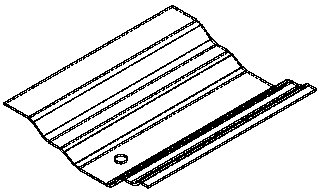

[0040] 2) Lay-up: Choose 0.25mm carbon fiber nylon prepreg, and use 2 / 1 structure to pave the surface-treated martensitic steel sheet and carbon fiber nylon prepreg. The specific structure is steel / 0° / 0° / 0° / 0° / steel.

[0041] 3) Heating and rapid transfer: Heat the...

Embodiment 2

[0047] Embodiment 2: An impact-liquid-filling-shot-peening integral forming method of a martensitic steel composite plate structure comprises the following steps:

[0048] 1) Surface treatment of martensitic steel: use acetone to clean and degrease the surface of 0.3 mm thick martensitic steel, and use phosphating solution for phosphating treatment after sandblasting. The formula of the phosphating solution used is: zinc nitrate 26g / L, zinc oxide 14g / L, sodium fluoride 8g / L, phosphoric acid 310m / L, nickel nitrate 6g / L, copper nitrate 0.03g / L, ethanol 7.5g / L, Surfactant OP-10 emulsifier 5g / L, surfactant sodium dodecylbenzenesulfonate 5g / L. The phosphating process is carried out at 25°C, the water temperature of the phosphating solution is controlled between 30°C, and the phosphating time is 10 minutes.

[0049] 2) Lamination: Choose 0.15mm carbon fiber reinforced nylon prepreg, and lay the surface-treated martensitic steel sheet and carbon fiber nylon prepreg in a 3 / 2 structur...

Embodiment 3

[0054] Embodiment 3: An impact-liquid-filling-shot-peening integral forming method of a martensitic steel composite plate structure, comprising the following steps:

[0055] 1) Surface treatment of martensitic steel: use acetone to clean and degrease the surface of 0.2mm thick martensitic steel, and use phosphating solution for phosphating treatment after sandblasting. The formula of the phosphating solution used is: zinc oxide 12 g / L, sodium nitrate 4 g / L, surfactant OP-10 emulsifier 5 g / L, surfactant sodium dodecylbenzene sulfonate 5 g / L, hydrogen Sodium oxide and phosphoric acid adjust the pH to 2~4. The phosphating process is carried out at 25°C, the water temperature of the phosphating solution is 26°C, and the phosphating time is 10 minutes.

[0056] 2) Lay-up: Choose 0.125mm carbon fiber nylon prepreg, and pave the surface-treated martensitic steel sheet and carbon fiber nylon prepreg in a 4 / 3 structure. The specific structure is steel / 0° / 90° / 0° / 90° / 0° / steel / 0° / 90° / 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com