Emergency braking and rheostatic braking combined control device for locomotive brake

A technology of resistance braking and emergency braking, which is applied in electric braking systems, railway braking systems, electric vehicles, etc., can solve the problems of unequipped trains, locomotive wheels locked, non-recoverable, etc., to improve safety and reliability , the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

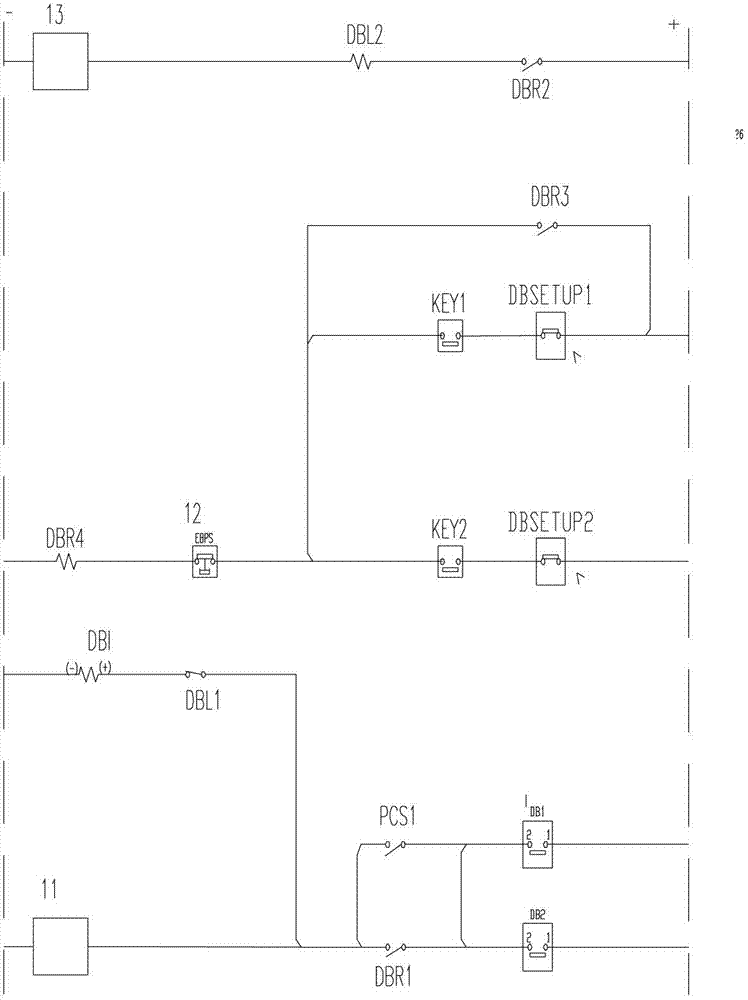

[0032] The invention discloses a joint control device for emergency braking and resistance braking of a locomotive braking machine. After braking, add a logic circuit for resistance braking, and a logic circuit for automatically judging whether to remove the air brake of the locomotive itself according to the magnitude of the resistance braking force.

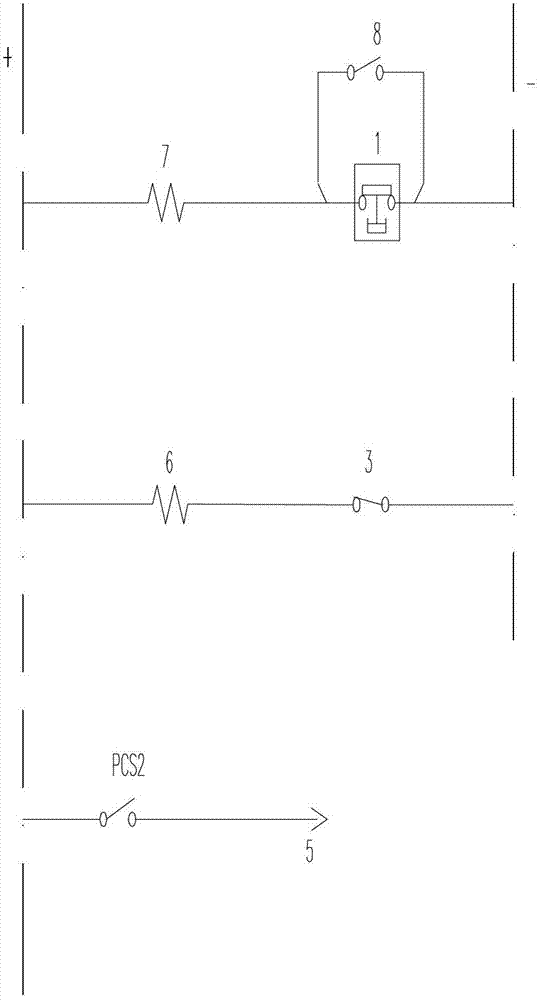

[0033] like figure 1 As shown, the logic circuit for automatically cutting off locomotive traction and resistance braking after emergency braking is composed of emergency braking pressure switch 1, wiring switch 8 for outputting the stop signal TJ of the train operation monitoring device, intermediate relay and power cutting Composed of relay PCS; the emergency braking pressure switch 1 is used to judge whether the locomotive has implemented emergency braking. When the locomotive is running normally, the pressure switch 1 is in the disconnected state; 1 is closed; after the emergency brake pressure switch 1 is connected in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com