Closed electrolytic pickling machine set

An electrolytic pickling and closed-type technology, which is applied in the direction of electrolytic components and electrolytic processes, can solve the problems of affecting the health of workers, the pickling liquid is easy to volatilize and escape, and the sealing effect is not good, so as to reduce the amount of waste acid water, Closed energy consumption, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

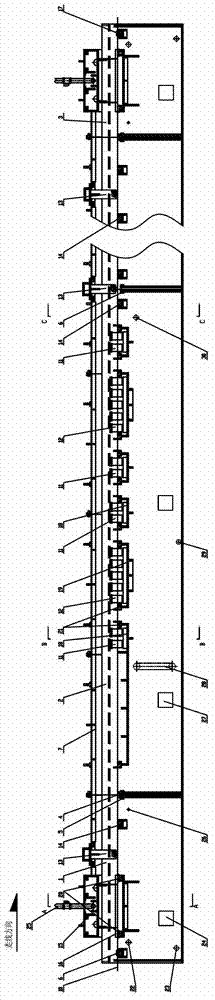

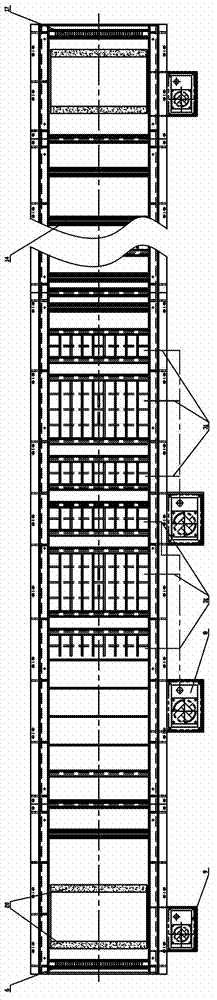

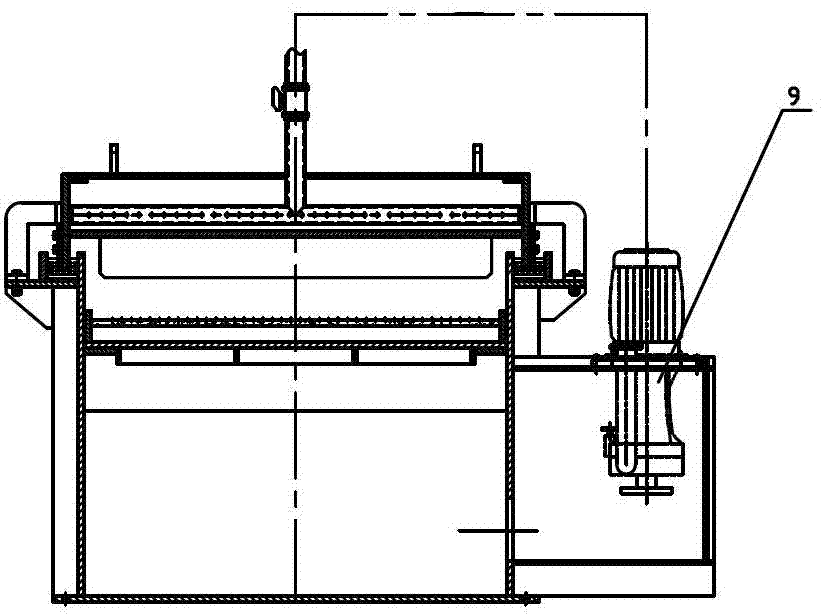

[0020] As shown in the figure: the closed electrolytic pickling unit in the embodiment is mainly composed of an incoming line water curtain tank 1, an electrolytic pickling tank 2, an outgoing line water curtain tank 3, a grinding stone at the connection point 4, a tank connecting plate 5, Line breakout grindstone 6, electrolytic pickling tank cover plate 7, acid pump box 8, water pump box 9, positive plate 11, negative plate 12, wire crimping cover 13, wire supporting grindstone 14, water curtain cover 15, Water curtain tank tray 16, outlet branch grinding stone 17, positive working tank 18, negative working tank 19, first grinding stone 20, second grinding stone 21, overflow pipe 22, drain pipe 23, suction pipe 24. It is composed of water inlet pipe 25, water adding pipe 26, acid pumping pipe 27, liquid level gauge 28, acid discharge pipe 29, acid adding pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com