Measurement system and method for measuring height of surface of micro object on basis of digital fringe projection technology

A fringe projection and technical measurement technology, applied in the field of measurement, can solve the problem that the optical microscope can only obtain the two-dimensional information of the measured object, etc., and achieve the effect of high utilization value, high precision and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

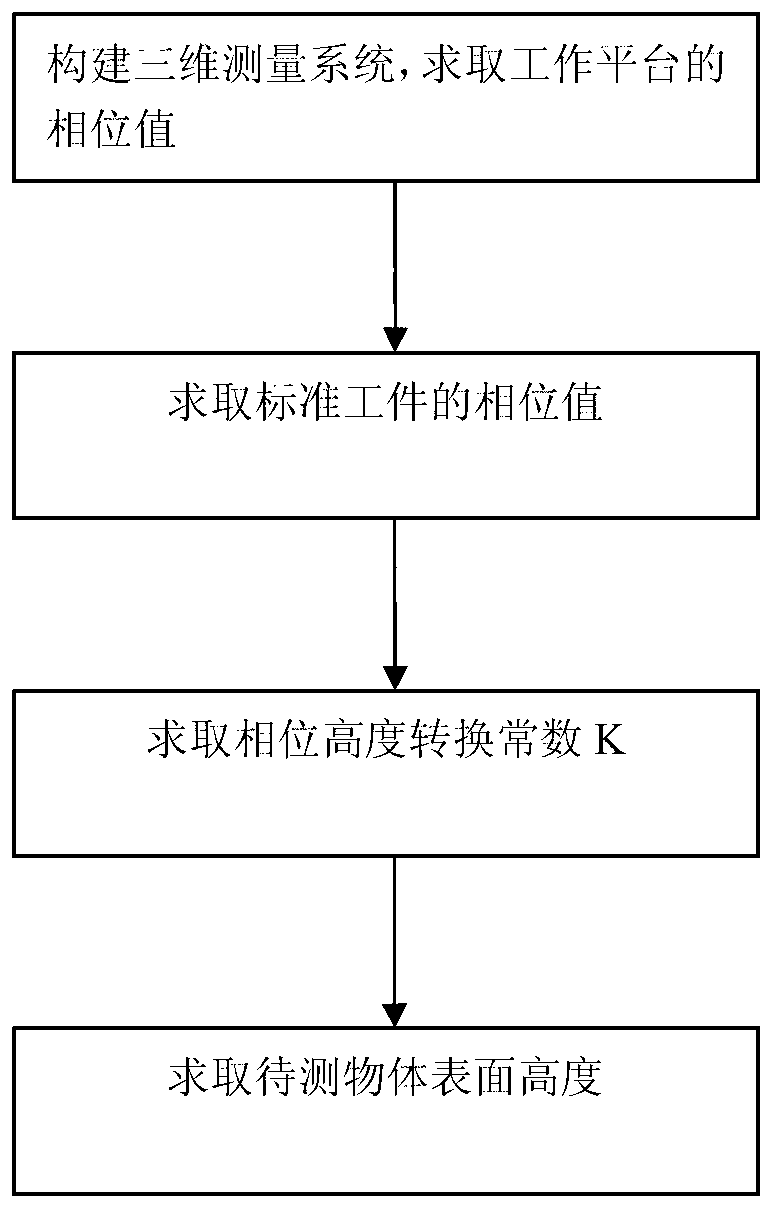

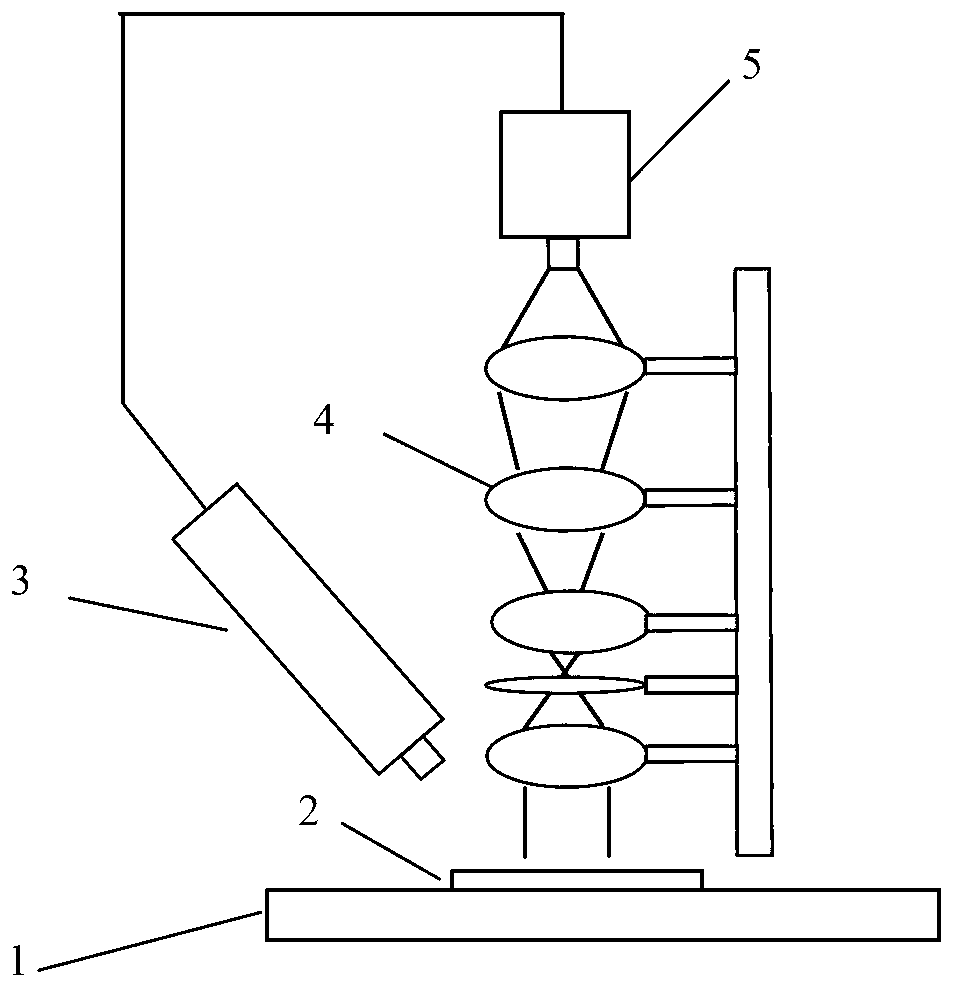

[0019] combine figure 2 , the present invention is based on digital fringe projection technology to measure the measurement system of the surface height of tiny objects, comprising a working platform 1, a TV microscope lens 3, a lens group 4 and a micro projector 5, and the TV microscope lens 3 is vertically placed downwards on the working platform 1, The lens of the micro-projector 5 can be placed on the same plane at an angle of 10°-30° downwards with the television microscope lens 3, and the lens group 4 is placed in front of the lens of the micro-projector 5 to focus the micro-projector 5 to project The sinusoidal fringe image of , the object 2 to be measured is placed on the working platform 1 . The order of the lenses of the lens group 4 from top to bottom is a biconvex lens with a focal length of 50.8mm, a biconvex lens with a focal length of 100mm, a doublet lens with a focal length of 75mm, a polarizer, and a focal length Be the biconvex lens of 100mm, take the lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com