Cavity bubble system of rubidium atom frequency standard

A technology of rubidium atomic frequency scale and cavity bubble, which is applied in the field of high-performance rubidium atomic frequency scale to achieve the effect of simple and effective adjustment of resonant frequency and reducing the volume of microwave cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

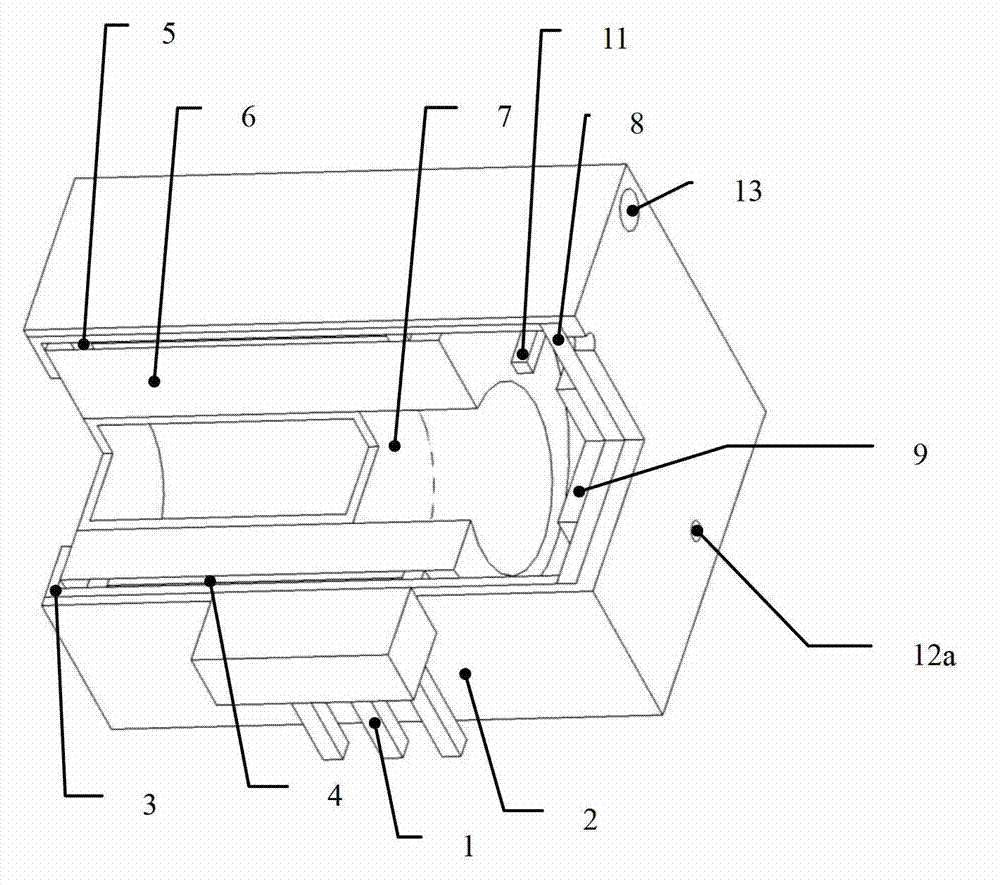

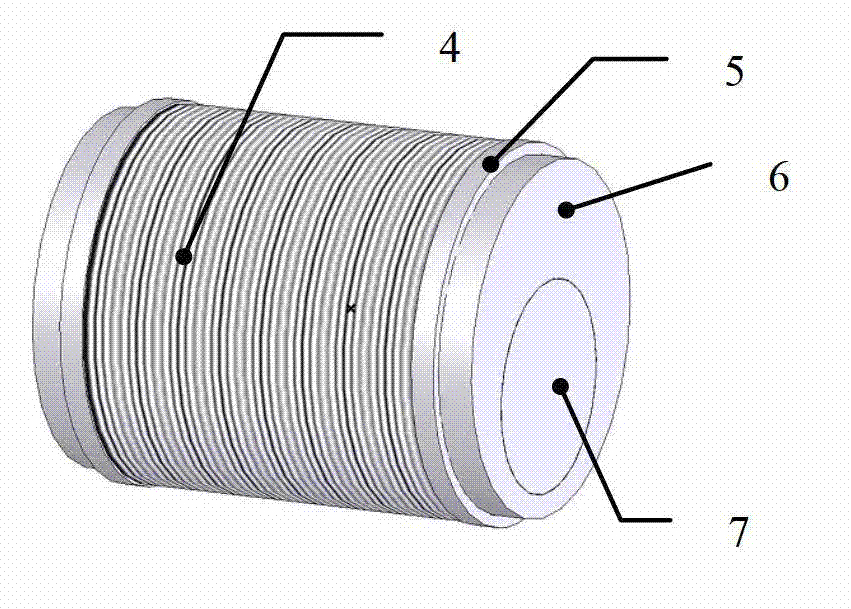

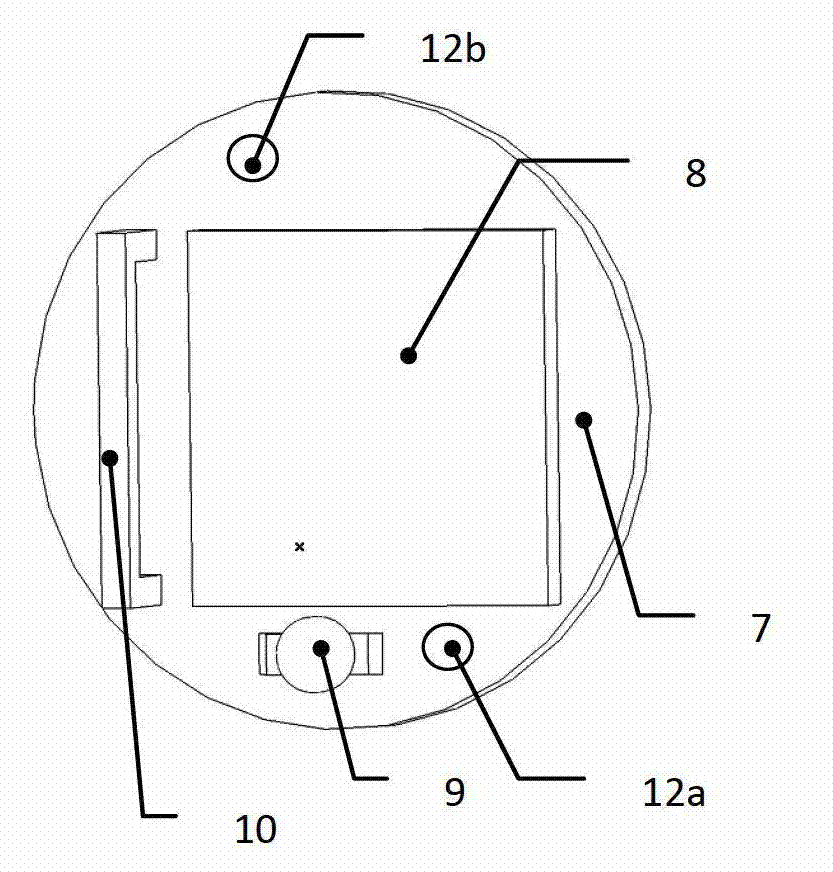

[0024] A rubidium atomic frequency standard cavity bubble system, which includes a heating power tube 1, a heating cylinder body 2, a microwave cavity body 3, a C field coil 4, an insulating snap ring 5, a dielectric cylinder 6, an integrated filter absorption bubble 7, and a microwave circuit plate 8, photocell 9, step diode 10 and coupling ring 11. It is characterized in that: the microwave cavity 3 is made of iron-nickel alloy or μ metal with high magnetic permeability, the microwave field type adopts TE111 mode, the coupling mode is magnetic coupling, and the direction of the microwave magnetic field is perpendicular to the coupling ring. In the entire integrated bubble, most of the microwave magnetic fields are directed along the direction of the quantization axis. The heating cylinder 2 has an outer square inner circle structure, and one end of the heating cylinder (2) is a fully closed end (only the RF cable, optical inspection line and C field coil outlet are left), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com