Automatic sludge conveying device for pressure filter

A conveying device and filter press technology, applied in conveyors, transportation and packaging, filtration and separation, etc., can solve the problems of high labor intensity, dirty ground, poor working environment, etc., to reduce labor intensity, and the ground will not be dirty. chaos, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

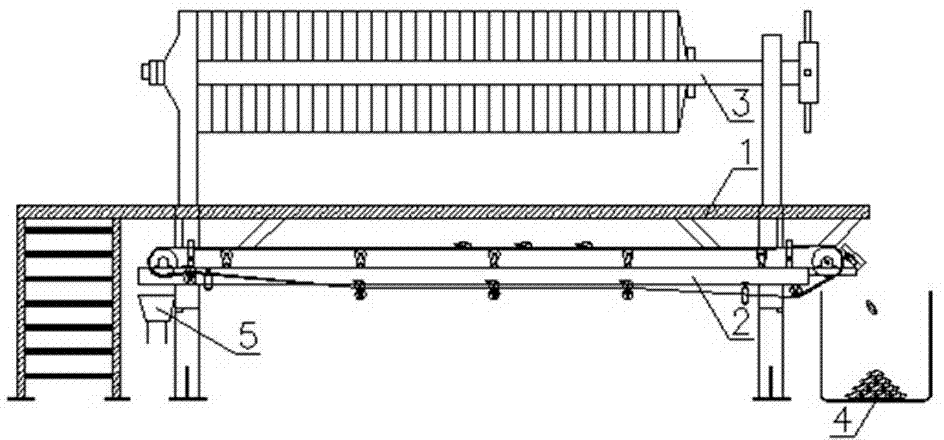

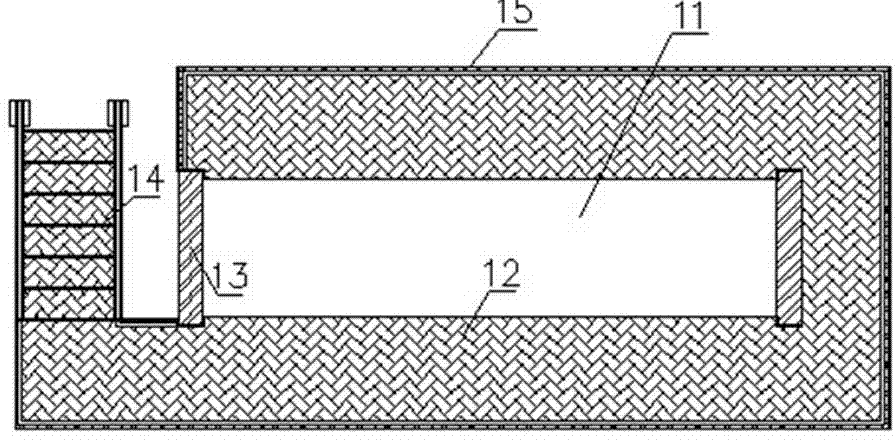

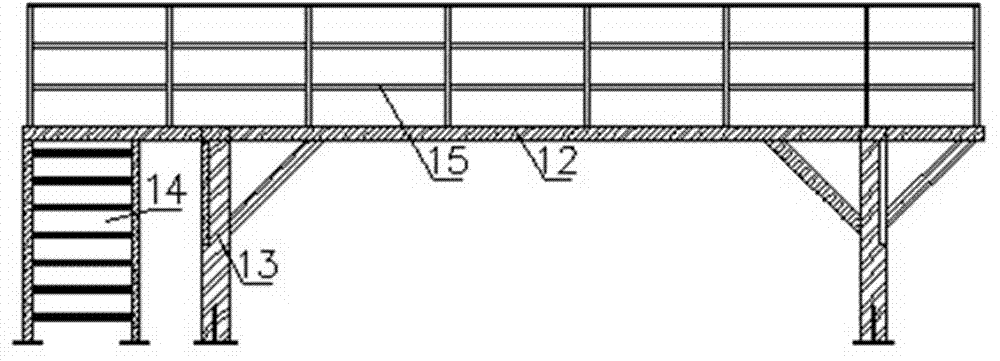

[0022] Embodiment: an automatic sludge conveying device for a filter press, including an operating platform 1 and a sludge conveying device 2, the filter press 3 is installed on the operating platform, and the operating platform 1 has a The mud leakage opening 11, the mud leakage opening 11 corresponds to the sludge discharge position of the filter press 3, the sludge conveying device 2 is installed under the operating platform 1, and the sludge discharging device 2 of the sludge conveying device 2 A mud loading device 4 is provided below the end 21. When the sludge of the filter press is ready to be unloaded, the filter press will automatically pull the plate, and the sludge will fall out of the filter press and onto the sludge conveying device, and the sludge conveying device will transport the sludge to the device. The sludge is bagged and packaged in the sludge device, so as to realize automatic sludge unloading and loading. The sludge does not need to be unloaded on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com