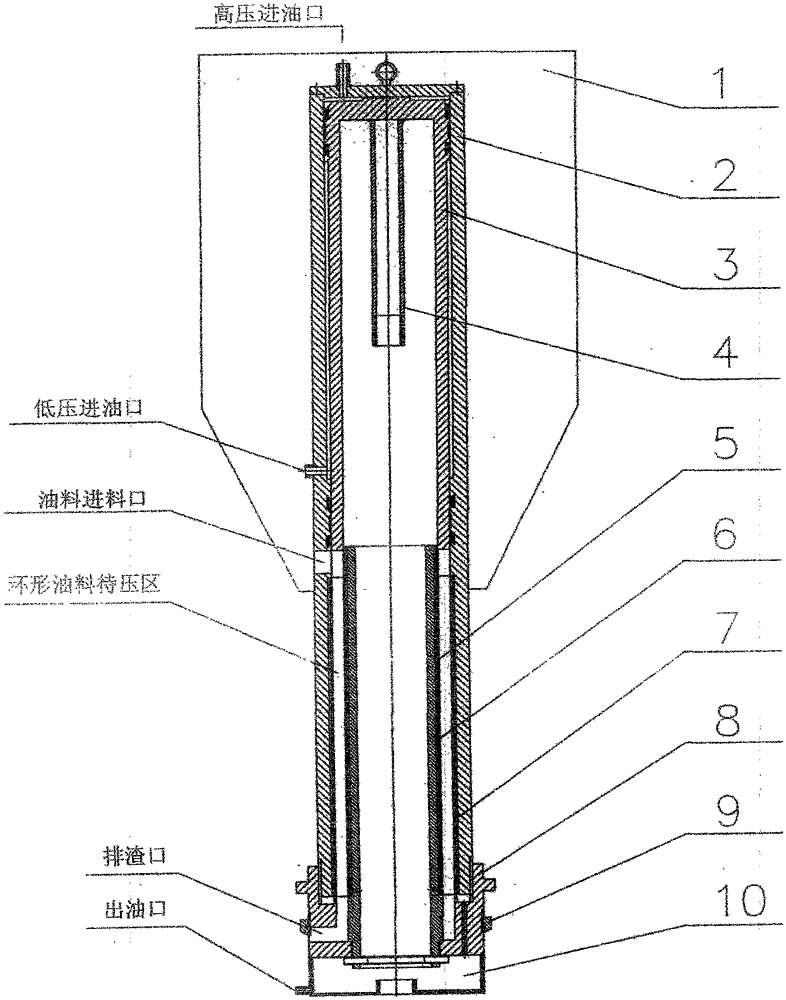

Fully automatic hydraulic oil press with double-sided oil output and automatic slag discharge

A technology of automatic slag discharge and hydraulic oil extraction, applied in the direction of presses, manufacturing tools, etc., can solve the problems of complicated operation, toxic residues, etc., and achieve the effect of exquisite structure, pure oil and fast oil extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the accompanying drawings, the oil storage bin (1) stores the oil after initial processing, and the oil is automatically injected into the ring-shaped waiting pressure between the inner filter tube (6) and the outer filter tube (7) through the oil feed port under the action of its own gravity. area. After starting the machine, the raw material pressure hollow plunger rod (3) moves from top to bottom to perform work, squeezing the oil in the annular area to be pressed, forcing the physical form and internal structure of the oil to change. ) there is a dense oil residue layer in the memory, and the oil that is splashed out can only seep out after being filtered through the slits on the inner filter tube (6) and the outer filter tube (7) from both inside and outside directions, and then go along the oil discharge channel on the filter tube It flows into the oil outlet and slag removal assembly (8), and then flows into the oil collection box (10). Simultaneously with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com