Wire tensioning mechanism for automatic wire winding and binding equipment and use method thereof

An automatic winding and equipment technology, applied to the parts of the strapping machine, etc., can solve the problems of difficult maintenance, high maintenance costs, low efficiency, etc., to facilitate automatic winding and bundling operations, low maintenance costs, and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

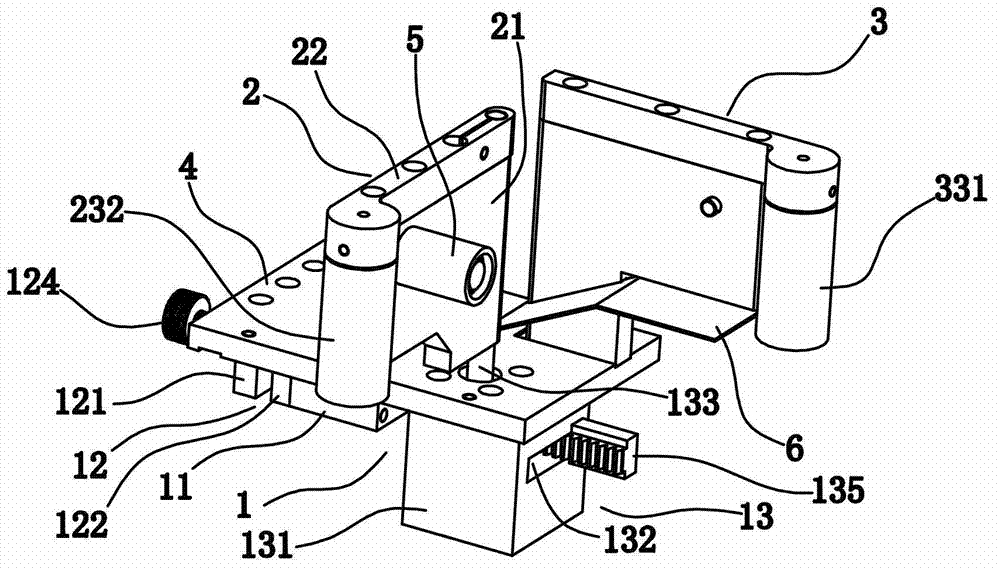

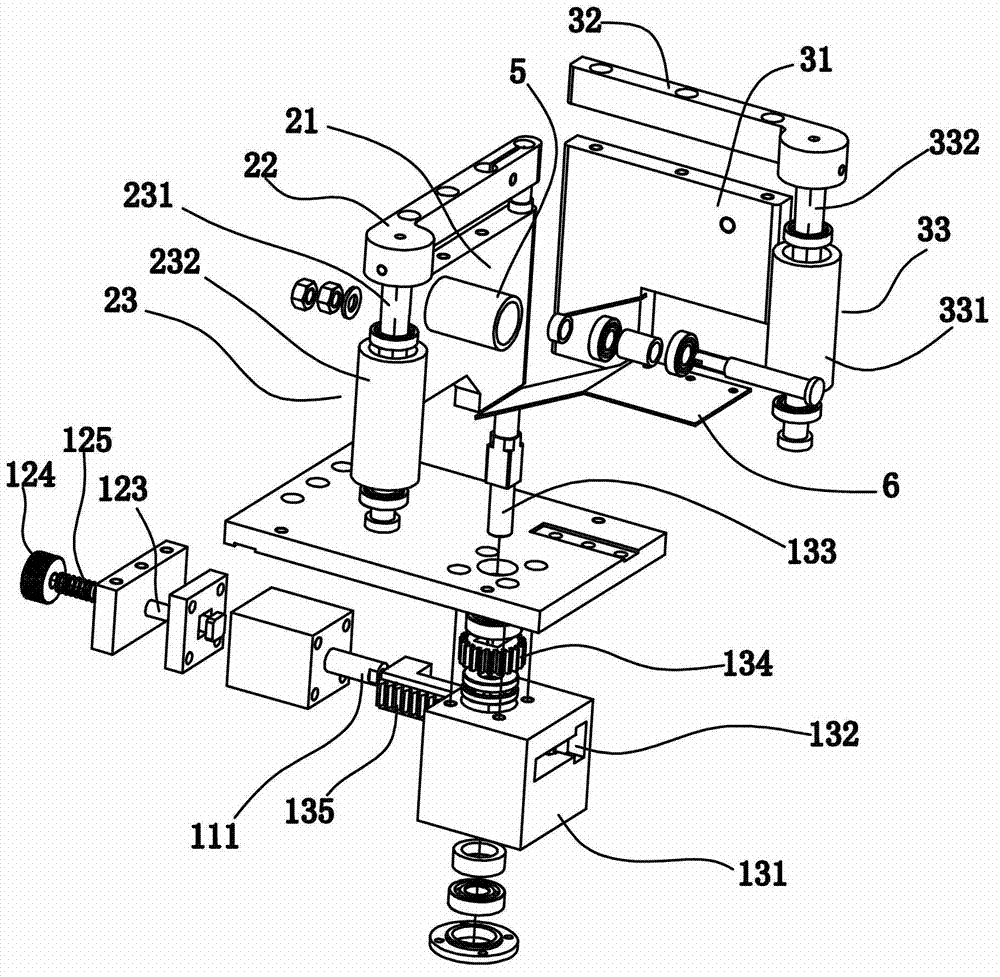

[0024] Example: see figure 1 and figure 2 , the present invention is a wire tensioning mechanism for automatic winding and binding equipment, which includes a power device 1, a movable splint 2 and a certain splint 3, the power device 1 is arranged under a bottom plate 4, and the movable splint 2 is rotatable It is arranged on the bottom plate 4 and connected with the power device 1, the power device 1 drives the movable splint 2 to swing, the fixed splint 3 is fixedly arranged on the bottom plate 4 and corresponds to the movable splint 2, when the movable splint 2 When swinging towards the fixed splint 3 and reaching the set position, the gap formed between the end of the movable splint 2 and the end of the fixed splint 3 will place the connecting wire ends between the movable splint 2 and the fixed splint 3 snapped and secured.

[0025] The power device 1 includes a cylinder 11, an adjustment assembly 12 and a gear assembly 13, the adjustment assembly 12 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com