Nested composite filter core

A composite filter element and filter element technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve problems such as unfavorable installation, increased use area, and inability to meet specific filtering requirements, so as to prolong the service life, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

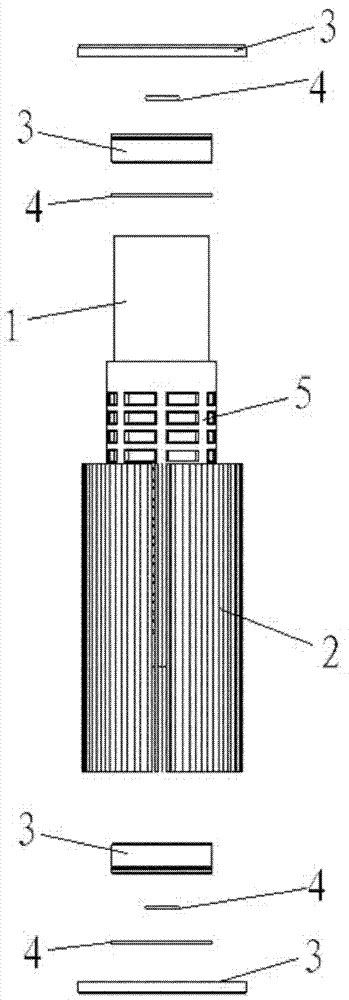

[0011] Embodiments of the stacked composite filter element of the present invention will be described in detail below with reference to the accompanying drawings.

[0012] The stacked composite filter element of the present invention includes first and second filter elements in the shape of hollow cylinders that are coaxially fitted to each other. equal height, and the outer diameter of the first-stage filter element matches the inner diameter of the second-stage filter element; both ends of the first and second-stage filter elements are provided with cover seals 3, and the cover seals 3 between the first and second-stage filter elements The gaskets 4 are tightly combined to form a whole, and then combined into a composite filter element, and the two-stage filter elements can be replaced separately.

[0013] The first-stage filter element is a compressed activated carbon filter element, and the second-stage filter element is one of a folded filter element and a fiber filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com