Crash structure vehicle front subframe attachment

A front subframe, connecting to the technology, applied in the direction of the connection between the upper structure, the lower structure, the upper structure sub-assembly, etc., can solve problems such as the adverse effect of the steering performance of the car, and achieve the effect of solid connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

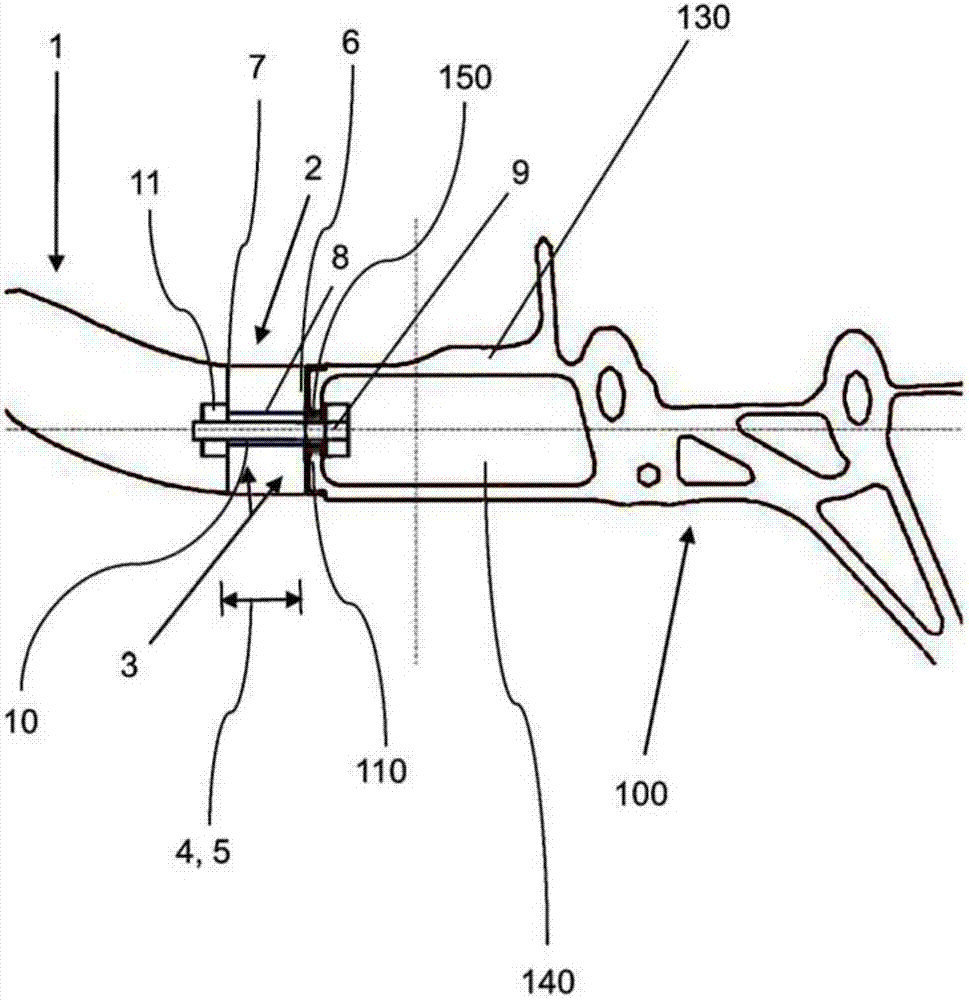

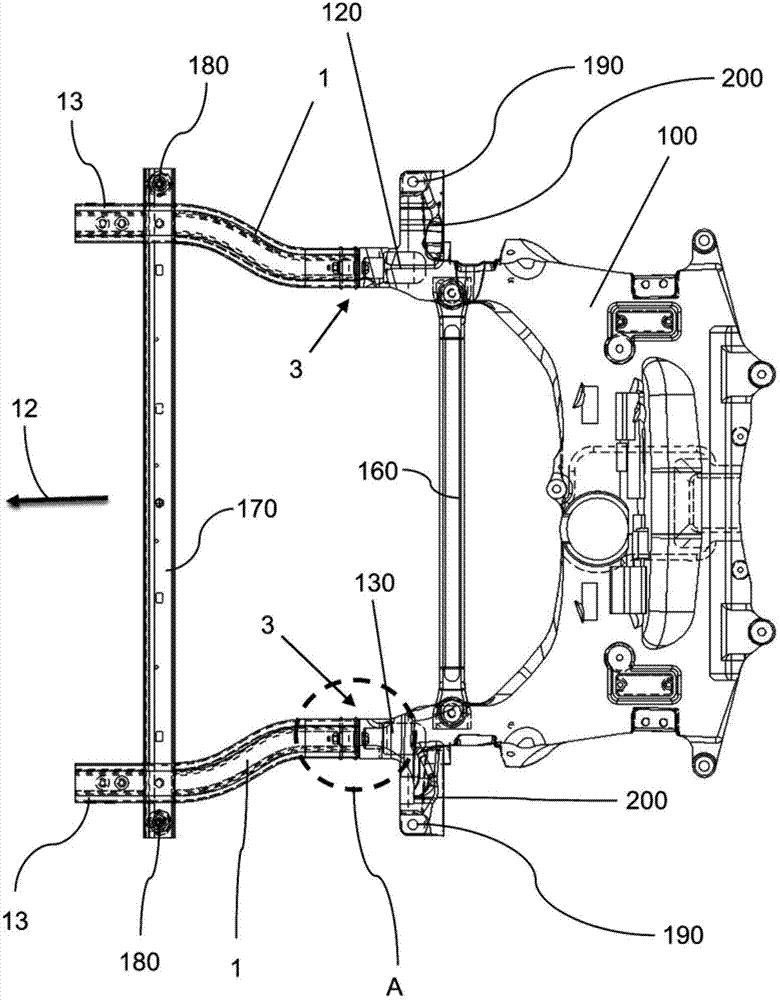

[0032] figure 1 A possible embodiment of a front subframe 100 , in particular a front axle subframe, is shown. The front subframe 100 is preferably U-shaped, wherein a possible embodiment of the crash structure 1 is fastened at the ends of its leg beams 120 , 130 .

[0033] The front subframe 100 serves, for example, to carry a steering gear of a vehicle steering system of a motor vehicle, at least one stabilizer, at least one bearing for the engine mount, a transverse link and an exhaust system. A tie rod 160 is preferably assigned to the front subframe 100 , via which the two leg members 120 , 130 of the front subframe 100 are connected to one another. The tie rods 160 are preferably hinged to the side beams 120 , 130 and serve to improve the rigidity of the front subframe 100 in the area of its side beams 120 and 130 .

[0034] The crash structure 1 , which is connected in each case to the ends of the side beams 120 , 130 of the front subframe 100 , is preferably elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com