Multi-core optical fiber discharging device

A multi-core optical fiber, fiber core technology, applied in the field of optical fiber production, can solve the problem of not being able to indicate fiber breakage in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

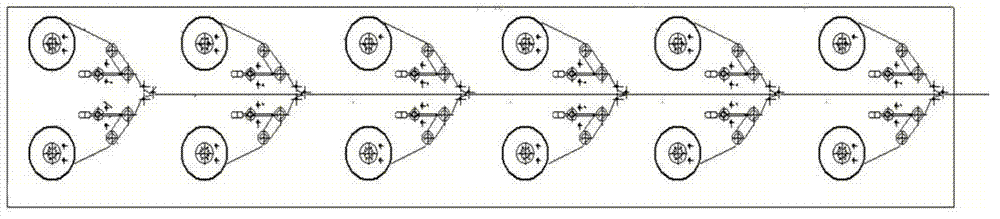

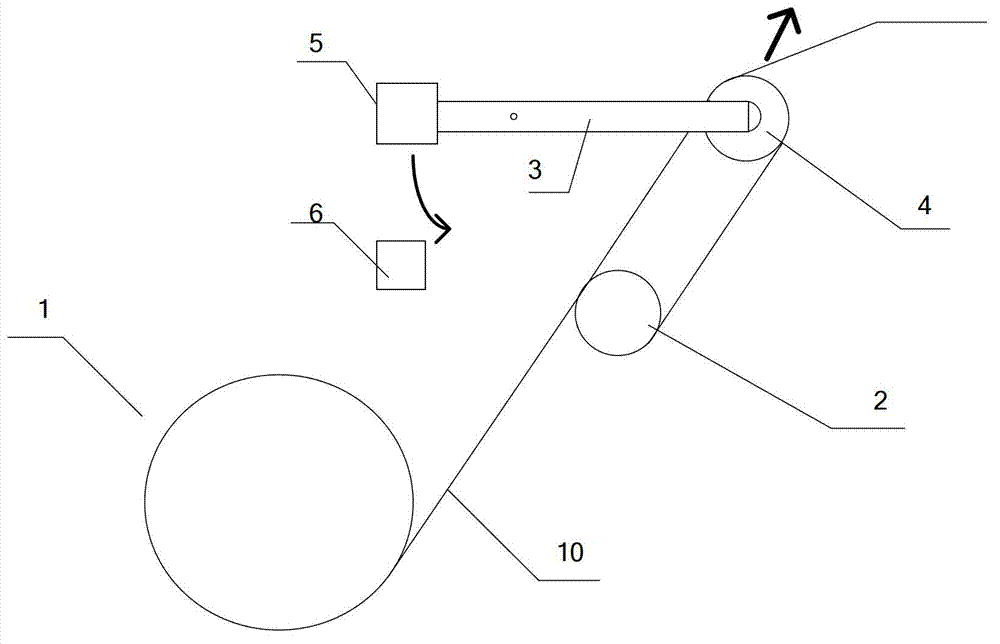

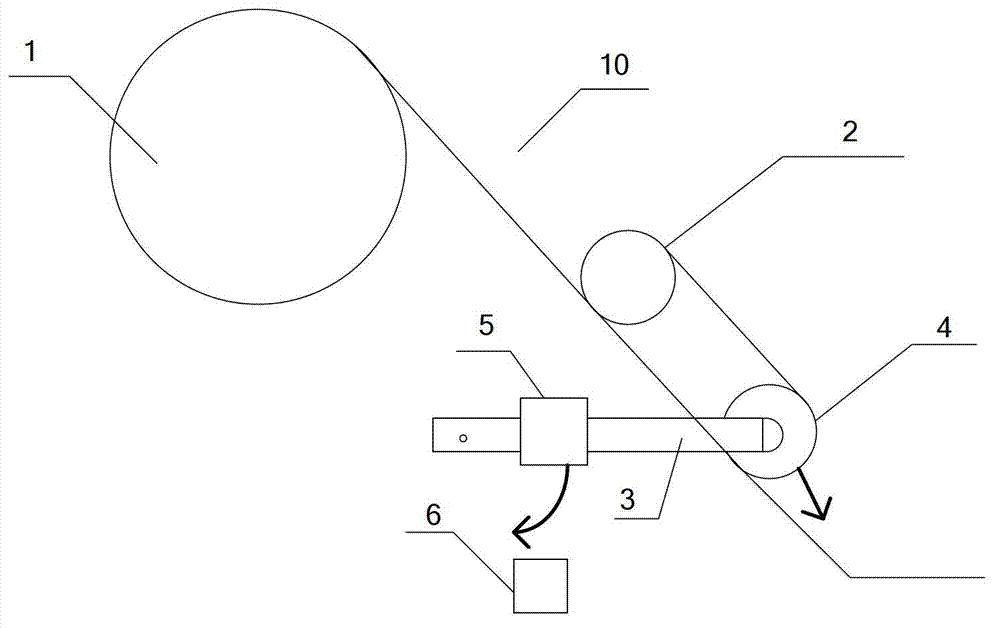

[0020] Such as figure 1 It is a 12-core fiber release device for secondary coated fibers. It is composed of 12 fiber cores to synthesize an optical fiber. Each fiber core comes from a tooth plate, and the number of tooth plates is the same as the number of fiber cores. Such as figure 2 , the crankset 1 is installed on the frame, and each crankset 1 is equipped with a pair of wire passing pulleys on the outlet side, one is the static pulley 2, and the other is the movable pulley 4, and the movable pulley 4 is connected with one to expand the distance between the movable pulley and the static pulley to increase the distance between the movable pulley and the static pulley. Tension device for fiber core tension, the tension device includes a tension swing rod 3 hinged on the frame, one end of the tension swing rod 3 is fixed on the rotating shaft of the movable pulley, and the tension swing rod 3 is connected with a driving tension swing rod to make the movable pulley and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com