Safety monitoring method and monitoring system for wind generating set tower and processing terminal

A technology for wind turbine safety monitoring, applied in the monitoring of wind turbines, control of wind turbines, wind turbines, etc., can solve problems such as performance failure, structural damage, and no monitoring, so as to increase safety and reduce waste of human resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

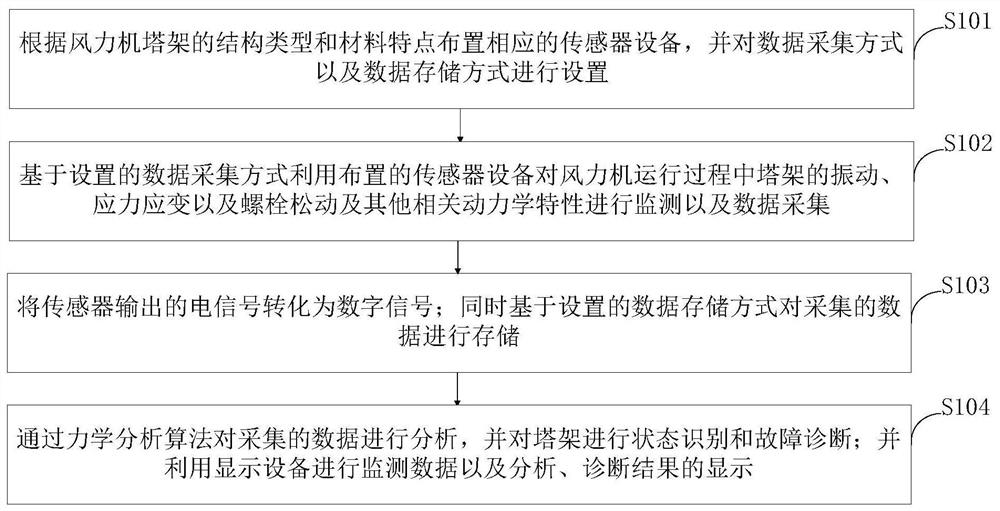

Method used

Image

Examples

Embodiment 1

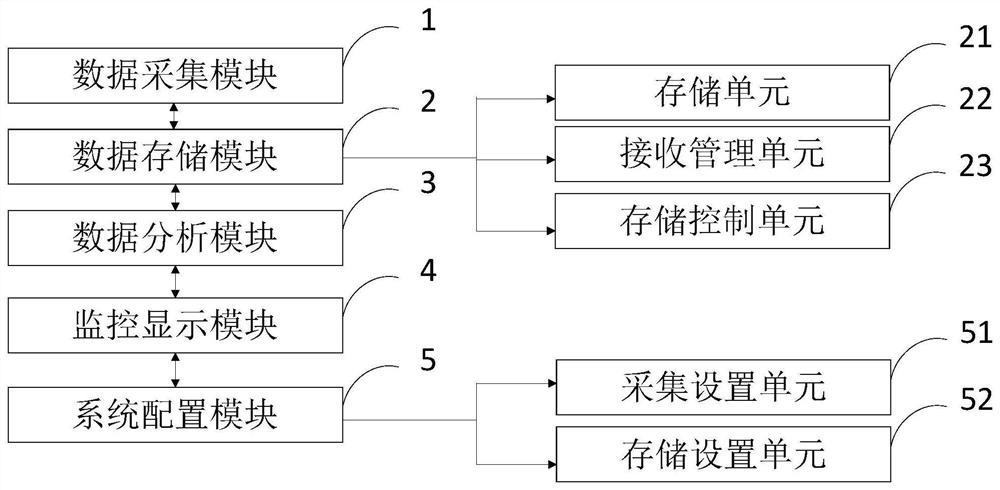

[0084] The safety monitoring system of the tower of the wind power generating set includes a data acquisition module, a data storage module, a data analysis module, a monitoring display module and a system configuration module.

[0085] The data acquisition module mainly realizes the communication control of the sensor equipment installed in the wind turbine, and collects the real-time data of the sensor according to the configured acquisition parameters and data storage strategy; it also includes a data communication interface, which can be connected through a wireless or wired LAN Send the collected data to the data storage module.

[0086] The data storage module obtains the monitoring data from the data acquisition module and stores them in the tower safety status monitoring database, and stores the basic information of the wind turbine and system configuration information at the same time. Manage the stored data and respond to the data query requirements of the monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com