Lifting appliance for turning cylindrical objects

A cylindrical, object technology, applied in the field of spreaders, can solve problems such as difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] In this embodiment, the stator of the turning motor is taken as an example to illustrate the structure of the spreader and the action of the spreader turning over a cylindrical object.

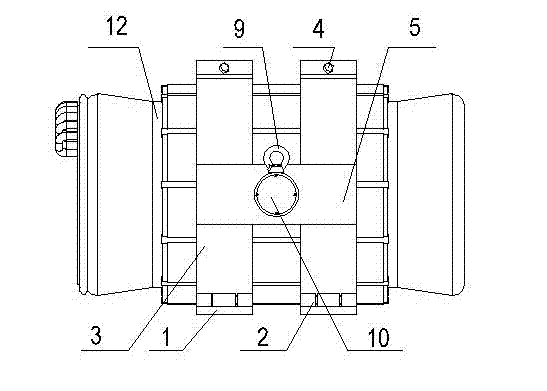

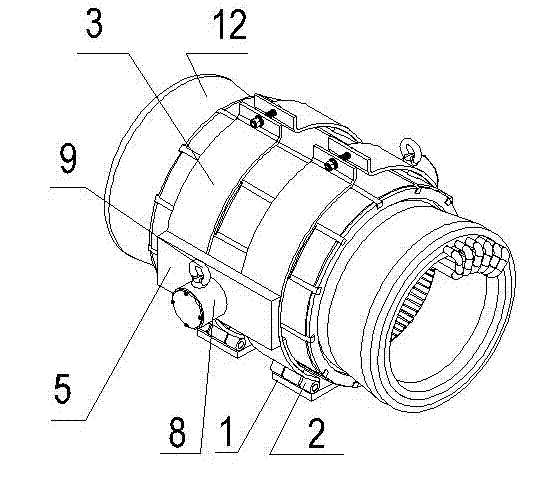

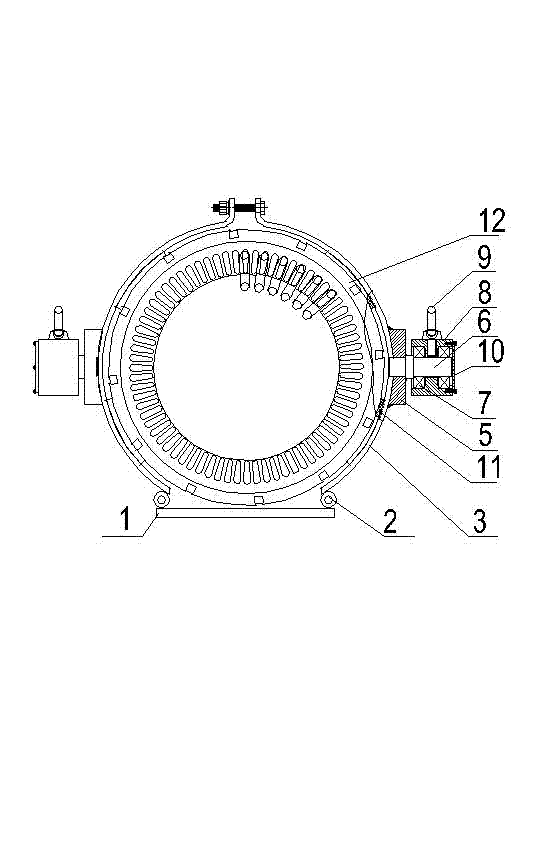

[0016] like figure 1 As shown, a lifting tool for turning cylindrical objects includes a bottom plate 1 for supporting cylindrical objects. The number of bottom plates 1 is reasonably selected according to the length of the cylindrical objects. If the object is short, one bottom plate is Yes, if the object is longer, the number of bottom plates can be appropriately increased. In this embodiment, the number of bottom plates is 2. The number of bottom plates in actual production is preferably 1-3, so as to facilitate the closing and alignment of the tire plates on both sides of the bottom plate as described below.

[0017] like figure 1 As shown, a tire plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com