Quantitative filling device and filling method thereof

A filling device and filling technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of not being able to meet the needs of filling large barrel containers, high cost of two-stage valves, limited flow, etc., and achieve easy control and maintenance, improve filling efficiency and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

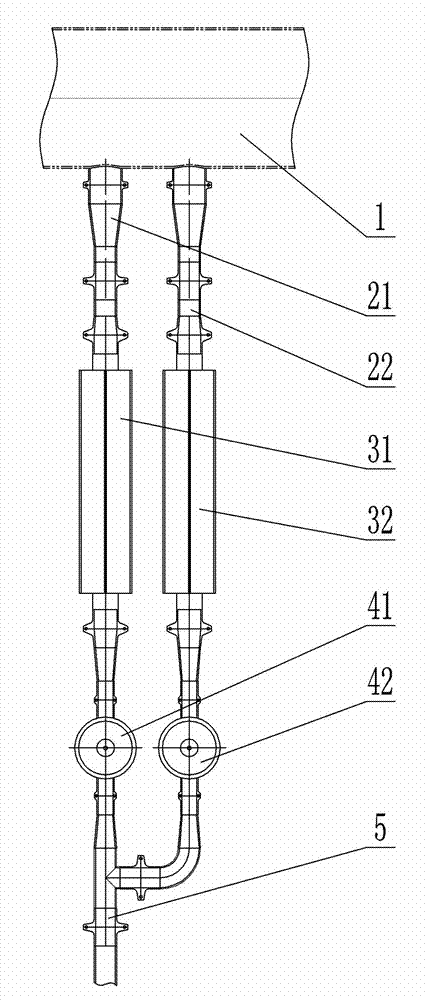

[0014] Embodiment one, such as figure 1 Shown is a two-channel quantitative filling device.

[0015] The quantitative filling device of the present invention has a liquid inlet pipe 1 for liquid to flow in, liquid flows out to a liquid outlet pipe 5 of the filling valve, and two circulation pipes 21 and 22 connecting the liquid inlet pipe 1 and the liquid outlet pipe 5, The liquid inlet ends of the flow pipes 21 and 22 are connected with the liquid inlet pipe 1, the liquid outlet ends of the flow pipes 21 and 22 are connected with the liquid outlet pipe 5, and the flow meters 31 and 32 and the control valve 41 are respectively installed on the flow pipes 21 and 22 , 42, the flow meters 31, 32 send the detected flow signals to the control valves 41, 42 to control the flow state of the flow pipes 21, 22, and the flow meters 31, 32 are in the front pipeline of the control valves 41, 42.

[0016] When the filling starts, the control valves 41 and 42 are opened, and the filling fl...

Embodiment 2

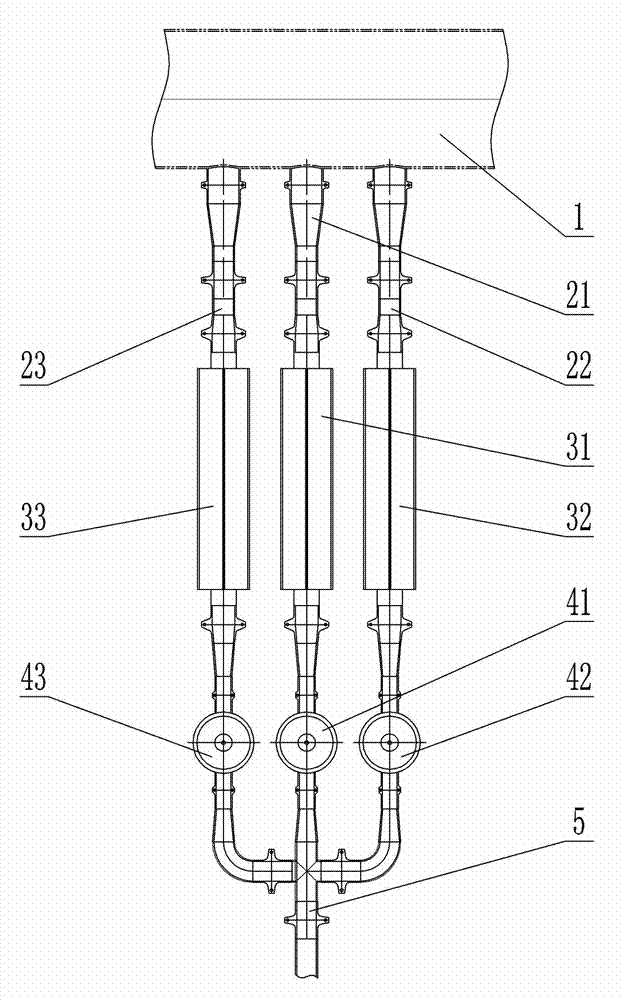

[0017] Embodiment two, such as figure 2 Shown is a three-channel quantitative filling device.

[0018] There are three flow pipes 21, 22, 23 connecting the liquid inlet pipe 1 and the liquid outlet pipe 5, and flow meters 31, 32, 33 and control valves 41, 42, 43 are respectively installed on each pipe. All the other are the same as the first embodiment.

[0019] When filling, the control valves 41, 42, 43 are opened, and the filling flow reaches the maximum. When the flow meters 31, 32, 33 detect the first value signal, the control valve 43 is closed, while the control valves 41, 42 remain open. state, the filling flow decreases. When the flow meters 31 and 32 detect the second value signal, the control valve 42 closes, while the control valve 41 remains open, and the filling flow is minimum. When the flow meter 31 detects the second value signal When the three-value signal is used, the control valve 41 is closed, and the filling stops.

[0020] The beneficial effect is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com