Ferromagnetic shape memory alloy with ultra high strength and its preparation method

An ultra-high-strength, memory alloy technology, applied in the field of metal alloys, can solve problems such as low restoring force, limiting the development of material engineering applications, and high brittleness of Ni-Mn-Ga bulk materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the atomic percentage, take 52 parts of Ni, 29 parts of Mn, 15 parts of Ga and 4 parts of Cu and put them into a vacuum non-consumable electrode electric arc furnace, wherein the placement order from top to bottom is Ni, Ga, Mn, Cu, Ni; under argon protection, 100A smelting current, 8A magnetic stirring current, arc melting for 20min, suction casting into a rod-shaped sample of Φ10mm×75mm in the device at the bottom of the water-cooled copper crucible, and then mechanical polishing, with Clean the alloy rod body with acetone, and then put it into a vacuum of 10 -2 In the quartz tube of Pa, it is kept at 850°C for 24 hours, and then quenched into water; that is, high-strength Ni 52 mn 29 Ga 15 Cu 4 Ferromagnetic shape memory alloys.

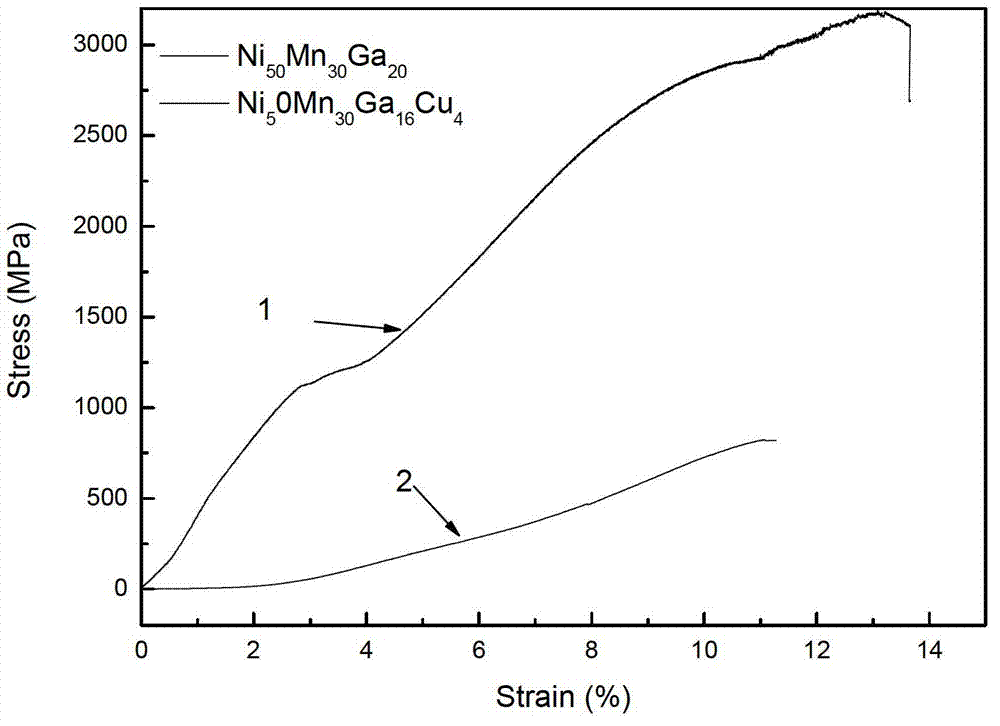

[0023] The Ni prepared in this example 52 mn 29 Ga 15 Cu 4 Alloys and Existing Ni 50 mn 30 Ga 18 Cu 2 The alloy was tested for fracture strength and fracture strain, and the test results were as follows: figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com