Novel reinforced composite wall body of detachable template

A technology for dismantling templates and composite walls, applied to walls, building components, buildings, etc., can solve the problems of slow construction progress, short construction period, and high efficiency, and achieve the effects of simple construction, convenient wall decoration, and reduced cost

Inactive Publication Date: 2012-11-21

北京京诚华宇建筑设计研究院有限公司

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the walls commonly used in steel structure buildings are block walls. Because the walls are masonry, they have good integrity, sound insulation and rainwater penetration resistance, but they also have certain shortcomings. If they want to achieve the current residential energy saving Standard, requires a thicker wall, or needs to add a layer of insulation material outside the wall

In addition, the block wall requires on-site wet work, and the construction progress is slow, which is inconsistent with the short construction period and high efficiency of the prefabricated steel structure system.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

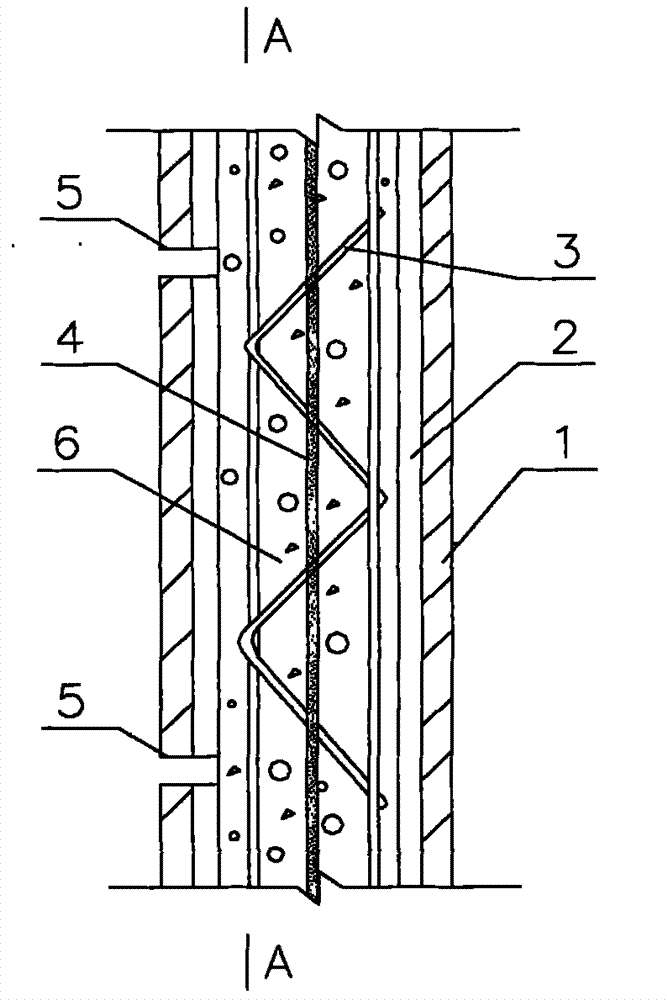

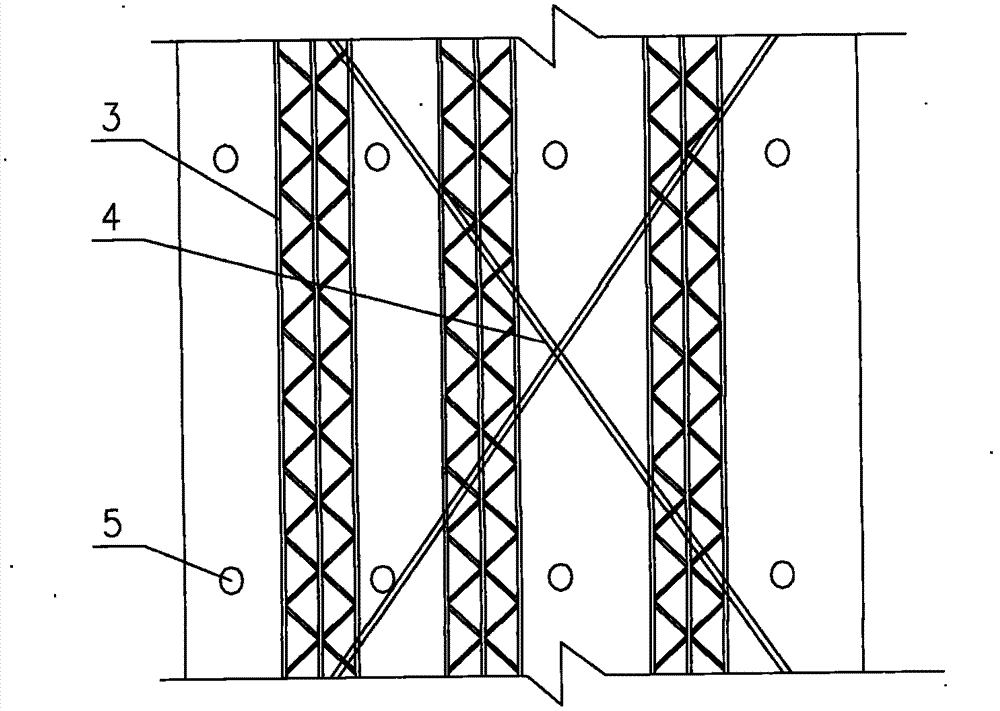

[0014] Embodiment: first use detachable formwork (1), gypsum inner formwork (2) and steel bar truss (3) to build the wall skeleton, set steel support (4) in the wall skeleton, and reserve perfusion on the wall formwork holes (5), lap the prefabricated wall skeleton on site, and finally pour lightweight concrete (6).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a novel reinforced composite wall body of a detachable template, belonging to the technical field of building structure engineering. The novel reinforced composite wall body of the detachable template mainly comprises a detachable outer template (1), a gypsum inner template (2), a steel bar truss (3), an inner support (4), and light concrete (5). The novel reinforced composite wall body of the detachable template is characterized in that a wall body skeleton is built by the detachable outer template (1), the gypsum inner template (2) and the steel bar truss (3); the steel support (4) is arranged inside the wall body skeleton, and a pouring hole (5) is preserved on the wall body template; the prefabricated wall body skeleton is lapped at the scene; and finally the light concrete (6) is poured. Compared with the common wall body, the novel composite wall body has the advantages of being low in construction cost and good in heat and sound insulation effects, capability of industrialization and being used for multiple times and being convenient to construct, energy-saving and environment-friendly and the like.

Description

technical field [0001] The invention is a novel reinforced detachable template composite wall, which belongs to the technical field of structural engineering. Background technique [0002] At present, the walls commonly used in steel structure buildings are block walls. Because the walls are masonry, they have good integrity, sound insulation and rainwater penetration resistance, but they also have certain shortcomings. If they want to achieve the current residential energy saving Standard, thicker walls are required, or a layer of insulation material needs to be added outside the wall. In addition, the block wall requires on-site wet work, and the construction progress is slow, which is inconsistent with the short construction period and high efficiency of the steel structure system assembly. [0003] The new reinforced detachable formwork composite wall combines detachable formwork, steel trusses and internal steel supports and other technologies, making full use of the c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B2/84E04B2/86

Inventor 余海群孙雅欣谭晋鹏贾凡李弢李虎

Owner 北京京诚华宇建筑设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com