Formwork-erecting-free self-bearing prefabricated ribbed beam concrete hollow laminated slab

A concrete and self-supporting technology, which is applied to floors, building components, buildings, etc., can solve the problems of unfavorable sustainable development and ecological civilization construction, noise, dust pollution, and long construction period, so as to reduce the binding work of steel bars and reduce the Energy consumption and environmental pollution, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

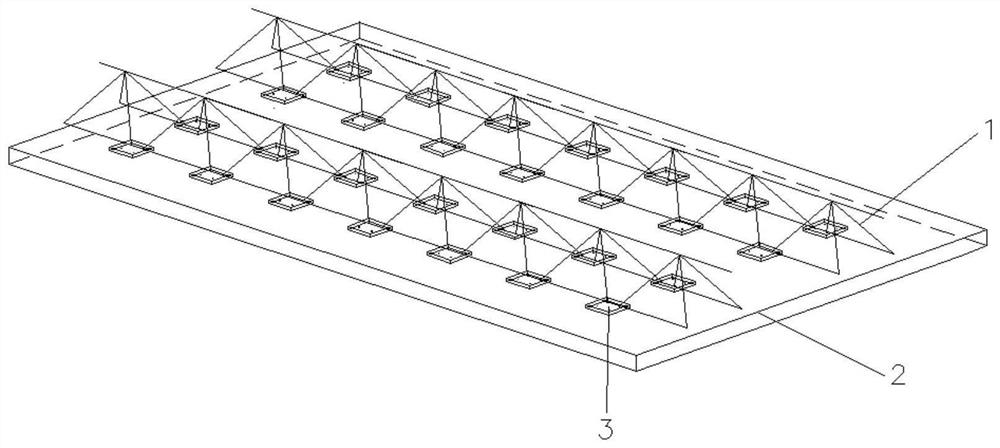

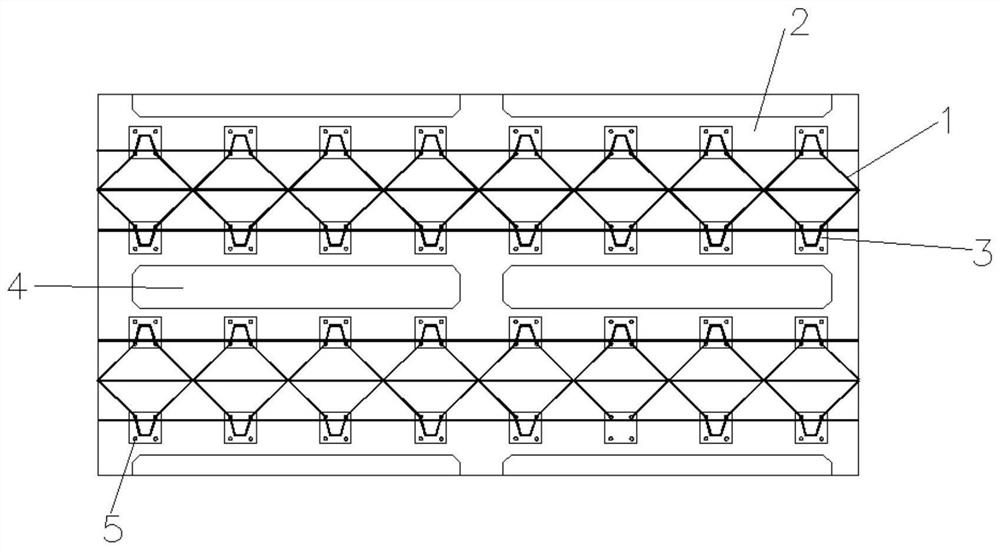

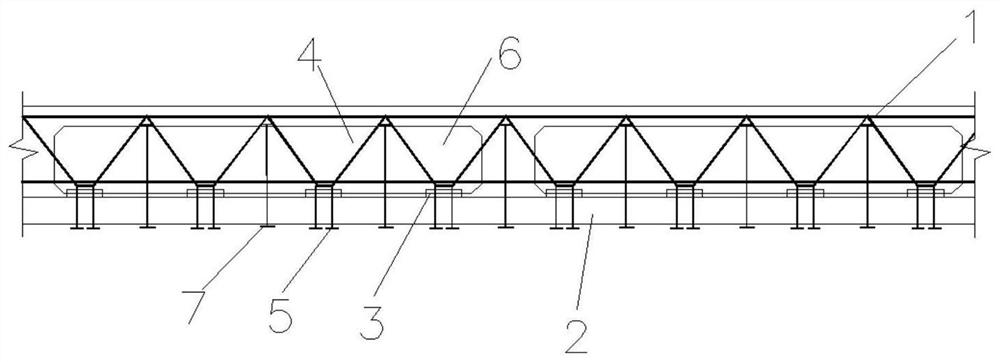

[0021] see Figure 1 to Figure 8 , a formwork-free self-supporting prefabricated rib beam concrete hollow laminated slab, comprising prefabricated cement fiber boards 2 and a plurality of prefabricated rib beams arranged at intervals along the transverse direction of the floor and extending longitudinally along the floor, and two adjacent prefabricated rib beams A hollow body 4 is arranged between them, and the hollow body 4 is fixed on the prefabricated cement fiber board 2 with an anchor 7, and the prefabricated rib beam is fixedly connected with the prefabricated cement fiber board 2 through the connecting plate 3 fixed at the bottom A concrete entity 6 is poured on the prefabricated cement fiber board 2 , and the hollow body 4 and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com