Method and device for producing a parylene coating

A parylene and cladding technology, which is applied in the field of manufacturing parylene cladding and devices, can solve the problems of long manufacturing time, cost, high technology and economy of cladding equipment, and achieve high output and realize output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] exist figure 1 A method 100 for producing a parylene coating on at least one surface of at least one component according to one embodiment is shown in .

[0047] In a first method step 101 of method 100 a first gas with parylene monomer is provided. In a further method step 102 a component arranged in an environment with atmospheric pressure is provided, and in a further method step 103 a first gas with parylene monomer is directed to at least one of said components by means of a first nozzle surfaces such that parylene monomer is deposited on at least one surface.

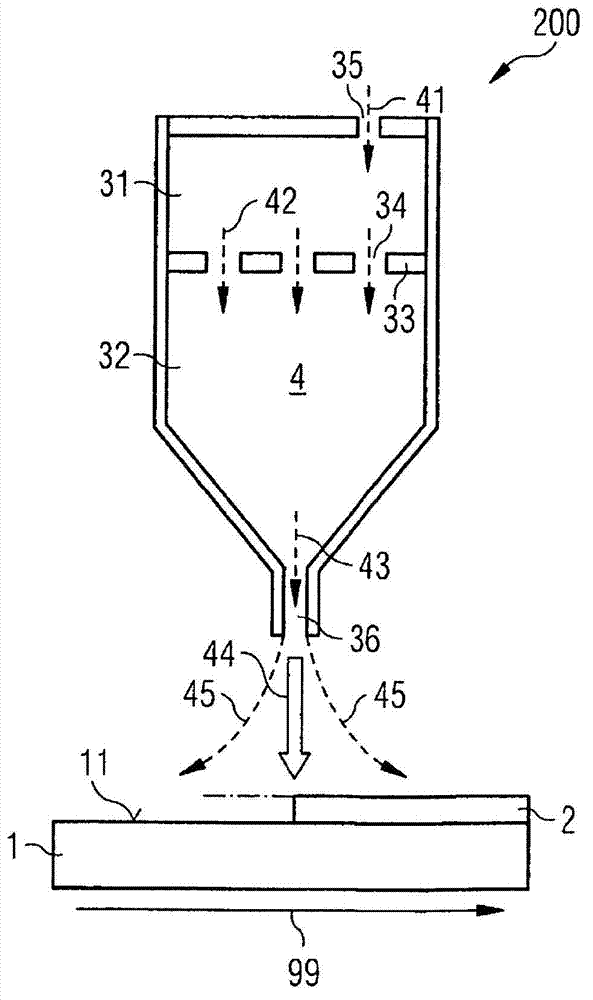

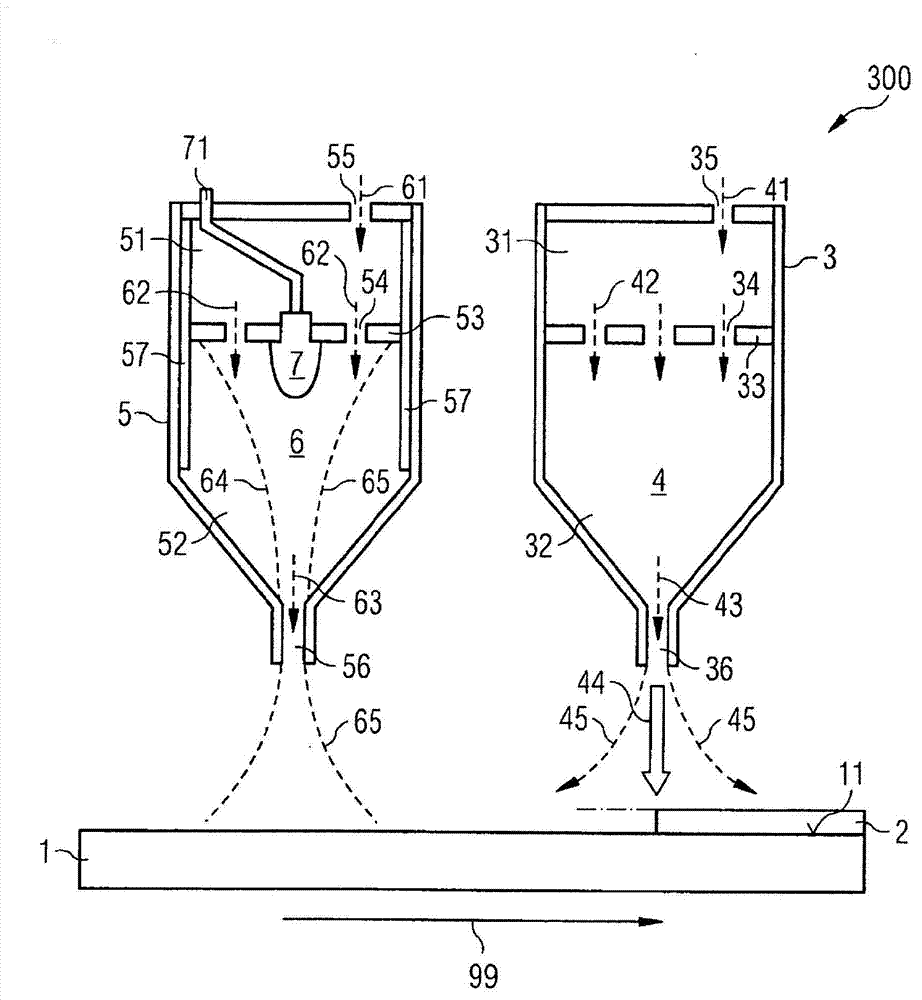

[0048] Embodiments of the method and other features are incorporated below Figures 2 to 5 The devices in the examples are illustrated.

[0049] exist figure 2 An exemplary embodiment of a device 200 for carrying out a method for producing a parylene coating 2 on at least one surface 11 of at least one component 1 is shown in FIG.

[0050] In the exemplary embodiment shown, the component 1 to be coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com