Mesh fence arc press machine in car

A fence and automobile technology, applied in the field of arc presses, can solve problems such as low efficiency and complicated stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

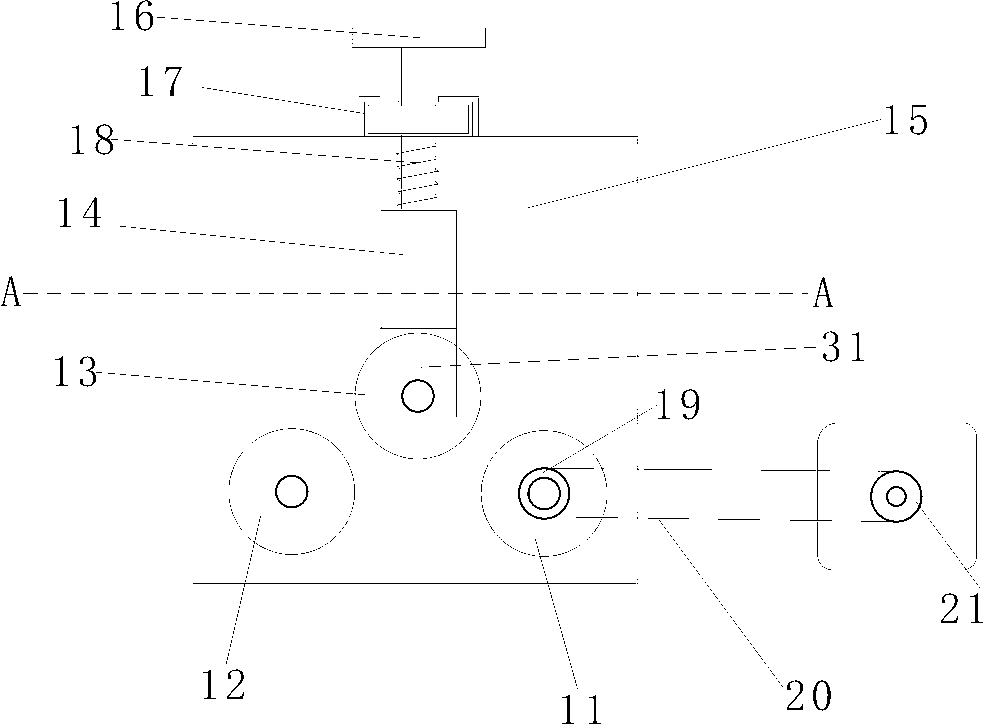

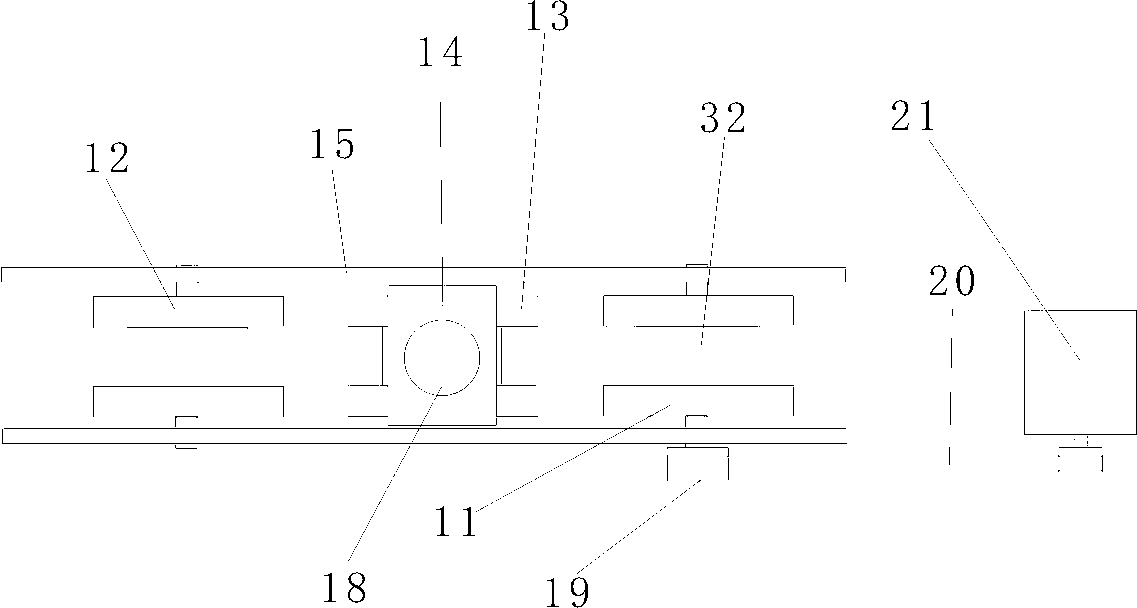

[0017] Embodiment 1: as figure 1 , figure 2 As shown in the figure, the arc pressing machine for the grid of automobiles includes an inlet roller 12, a middle roller 13, and an outlet roller 11; the three rollers are on the same plane; the inlet roller 12 and the outlet roller 11 are fixed on the mounting frame 15 At the same time, the mounting frame 15 also plays the role of a baffle, the middle pressure roller 13 is located above the middle position between the inlet pressure roller 12 and the outlet pressure roller 11, and the top of the middle pressure roller 13 is connected to the pressure roller longitudinal adjustment device; the outlet pressure roller 11 is connected to the transmission device; Grooves 32 are provided on the outer edges of each pressure roller.

[0018] The transmission device includes a motor 21 , a belt 20 , and a transmission wheel 19 ; one end of the belt 20 is connected to the motor 21 , the other end of the belt 20 is connected to the transmiss...

Embodiment 2

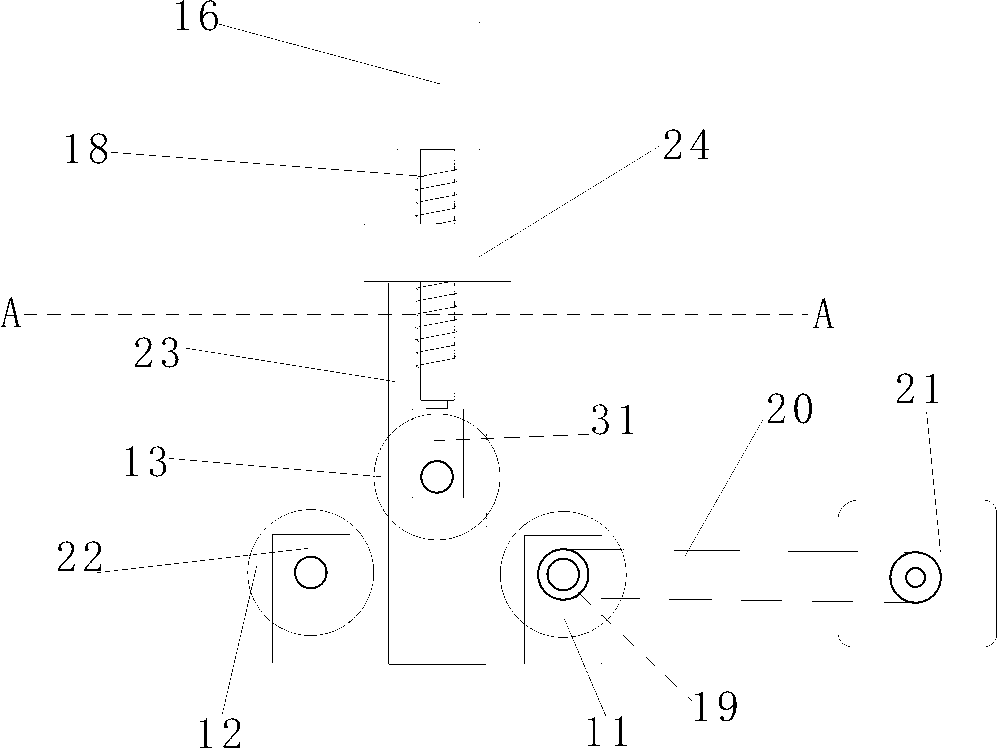

[0022] Embodiment 2: as image 3 , Figure 4 , Figure 5 As shown in the figure, the arc pressing machine for the grid of automobiles includes an inlet roller 12, a middle roller 13, and an outlet roller 11; the three rollers are on the same plane; the inlet roller 12 and the outlet roller 11 are fixed on the mounting frame 22 , the middle pressure roller 13 is located above the middle position between the inlet pressure roller 12 and the outlet pressure roller 11, the upper part of the middle pressure roller 13 is connected with the pressure roller longitudinal adjustment device; the outlet pressure roller 11 is connected with the transmission device; the outer edge of each pressure roller is provided with a groove 32 .

[0023] The transmission device includes a motor 21 , a belt 20 , and a transmission wheel 19 ; one end of the belt 20 is connected to the motor 21 , the other end of the belt 20 is connected to the transmission wheel 19 , and the transmission wheel 19 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com