Polymer electrolyte based on ionic liquid and preparation method and application thereof

A technology of ionic liquid and polymer, which is applied in the direction of solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte, etc., can solve environmental damage and other problems, and achieve the effects of strong solid-state performance, high safety performance, and high solid-state performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of an ionic liquid-based polymer electrolyte and a solid-state battery:

[0045] 1. Preparation of lithium lanthanum titanyl oxide (LLTO)

[0046] First weigh 1g lithium nitrate (LiNO3) and 6g lanthanum nitrate hexahydrate (LaNO3) 3 ·6H 2 (0), after it is packed into a beaker, dissolve with 10g absolute ethanol to obtain solution 1.

[0047] Then take another beaker, weigh 6g of tetrabutyl titanate and 2g of acetylacetone, and stir at 600r / min for 0.5h to obtain solution 2.

[0048] Solution 1 and solution 2 were mixed, and the mixed solution was stirred for 1 h.

[0049] The yellow solution obtained after the stirring was completed was dried in a blast drying oven at 70 degrees Celsius for 5 days, and then dried in a vacuum drying oven at 70 degrees Celsius for 24 hours to obtain a khaki xerogel.

[0050] The xerogel was put into a covered crucible and calcined at 900 °C for 2 h to obtain LLTO as a white powder.

[0051] The obtained white pow...

Embodiment 2

[0084] A preparation method of an ionic liquid-based polymer electrolyte and a solid-state battery:

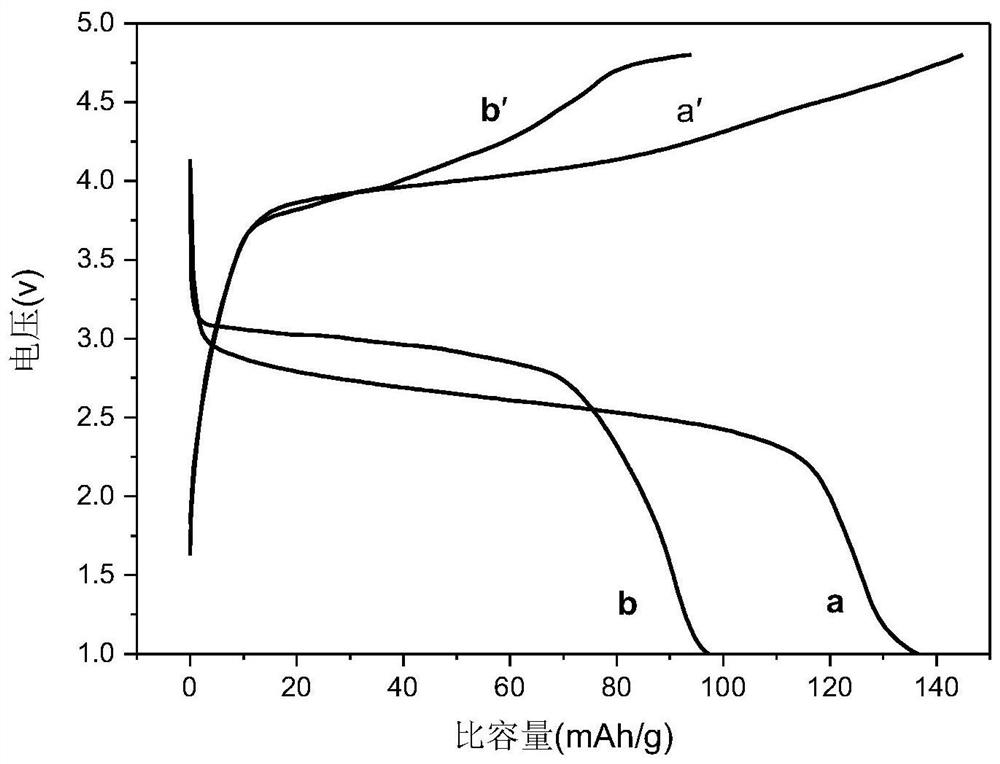

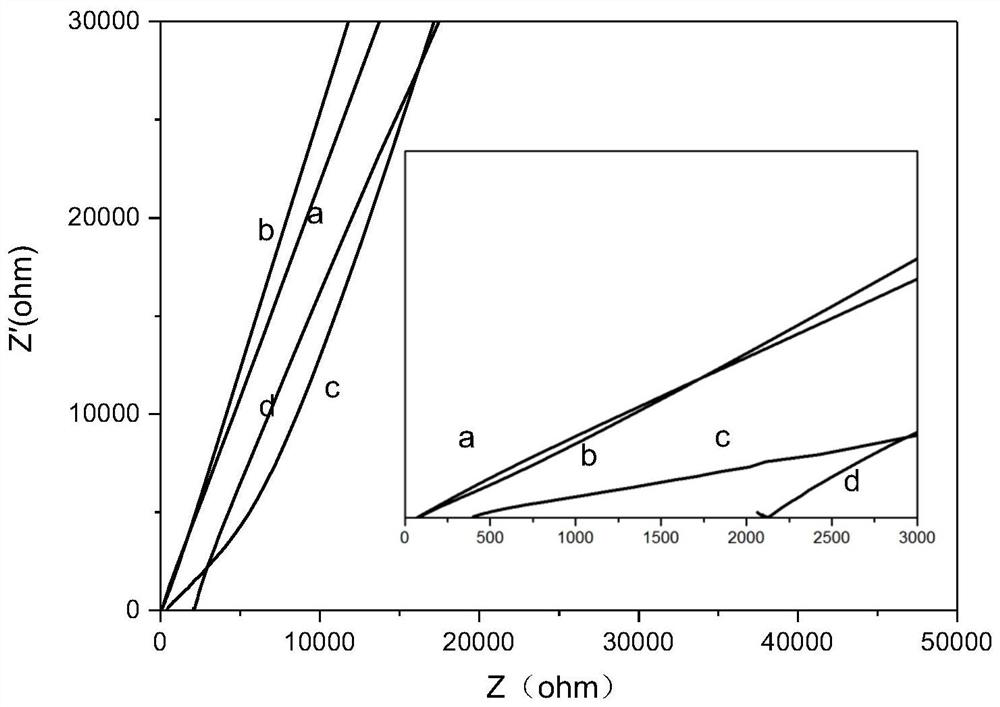

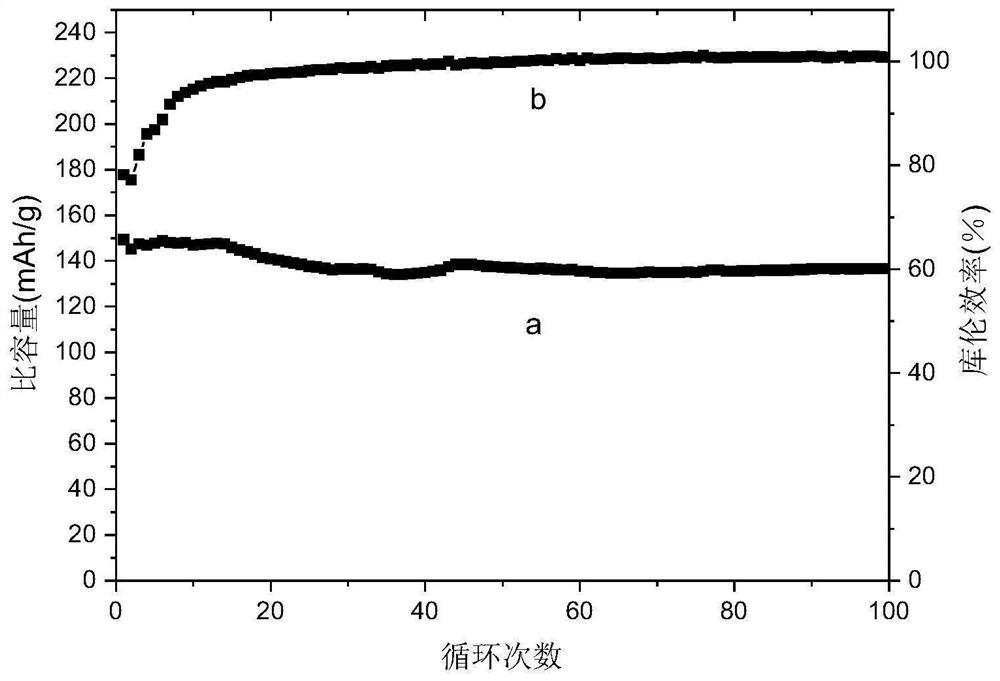

[0085] Other experimental conditions are the same as in Example 1, and the difference from Example 1 is that in the preparation process of the polymer electrolyte in step 3, 0.2231g of nano-scale SiO is weighed 2 0.2231g of lithium lanthanum titanyl oxide (LLTO) and 0.1g of azobisisobutyronitrile (AIBN) were put into a 5ml glass bottle. Then add 0.3346g lithium salt LiTFSi and 0.35g ionic liquid [Py14]NTf2. The battery impedance test results are as follows figure 2 As shown, the ionic conductivity results are shown in Table 2.

Embodiment 3

[0087] A preparation method of an ionic liquid-based polymer electrolyte and a solid-state battery:

[0088] Other experimental conditions are the same as in Example 1, and the difference from Example 1 is that in the preparation process of the polymer electrolyte in step 3, 0.2071g of nano-scale SiO is weighed 2 , 0.1036g of lithium lanthanum titanyl oxide (LLTO) and 0.1g of azobisisobutyronitrile (AIBN) were put into a 0.5ml glass bottle. Then add 0.3107g lithium salt LiTFSi and 0.35g ionic liquid [Py14]NTf2. The battery impedance test results are as follows figure 2 As shown, the ionic conductivity results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com