End cap modification device

A technology of end cap and drive device, applied in the field of component processing, to achieve the effect of the same height, the same bevel angle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

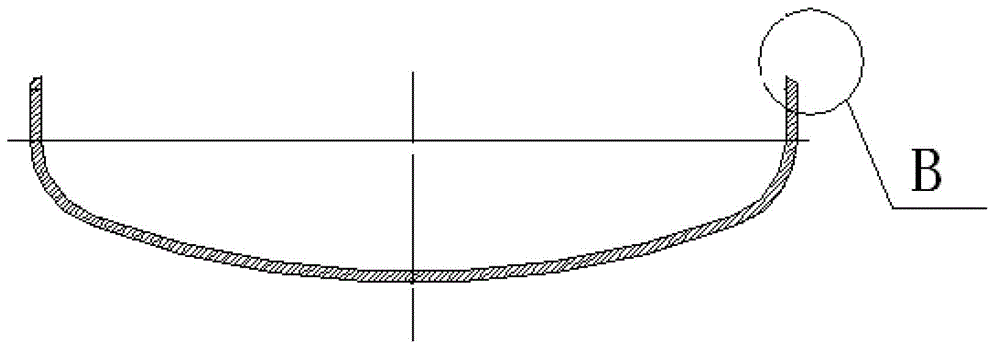

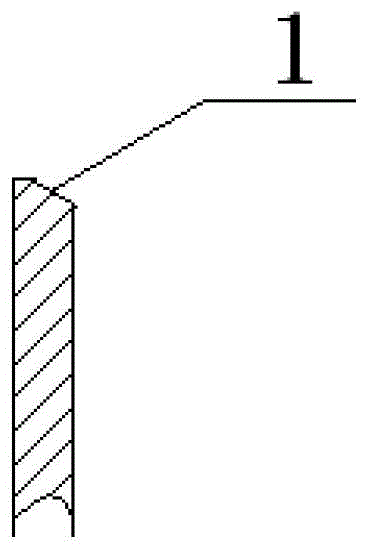

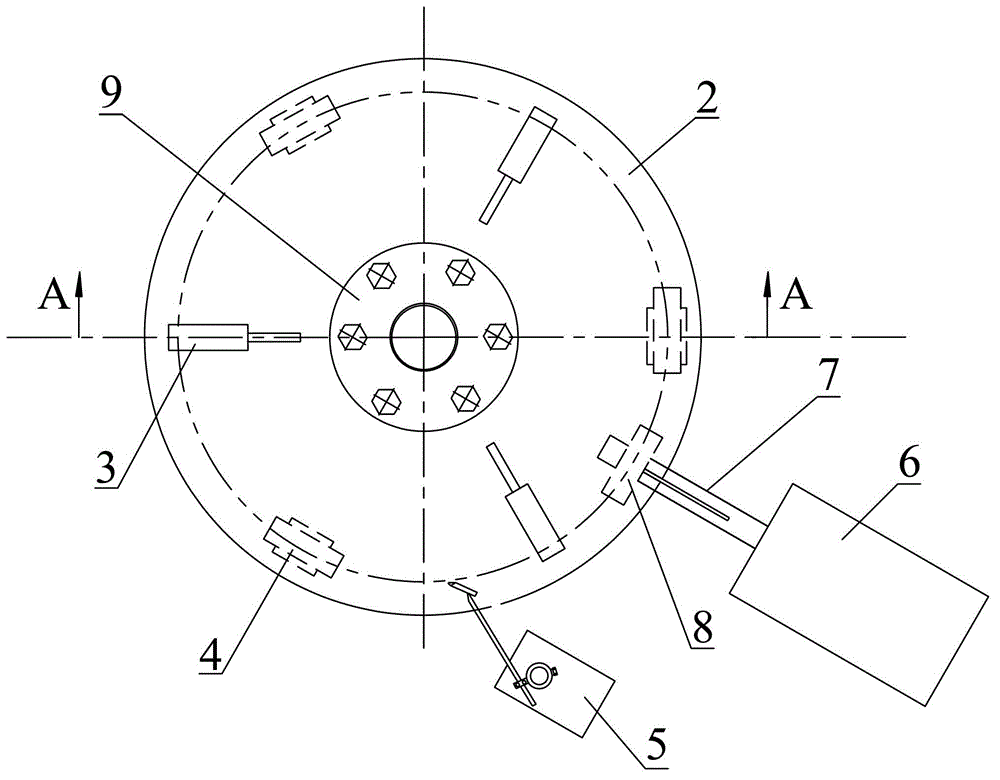

[0026] image 3 It is a top view of the end cap modification device of the present invention; Figure 4 for image 3 AA sectional view of ; Figure 5 It is a schematic diagram of the connection between the connecting shaft and the driving wheel; Figure 6 Schematic diagram of the height adjustment device.

[0027] This embodiment provides a device for modifying end caps, such as image 3 and Figure 4 As shown, it includes a turntable 2, a limit post 10, a support post 12, a torch support 5 and a driving device.

[0028] The turntable 2 used in this embodiment is a ring-shaped metal disk, and the top of the turntable 2 is provided with a support for fixing the end cover that matches the end cover; A support block 3 matched with the outer edge of the end cover.

[0029] The center of the turntable 2 is pierced with a limit pillar 10, and the inner ring of the turntable 2 close to the limit pillar 10 is provided with a bearing 11; the position above the turntable 2 close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com