Bicycle pneumatic tyre used for irregular road surfaces

A pneumatic tire, irregular technology, applied to tire parts, tire tread/tread pattern, vehicle parts, etc., can solve problems such as increased inertia, high energy loss, and reduced groove volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

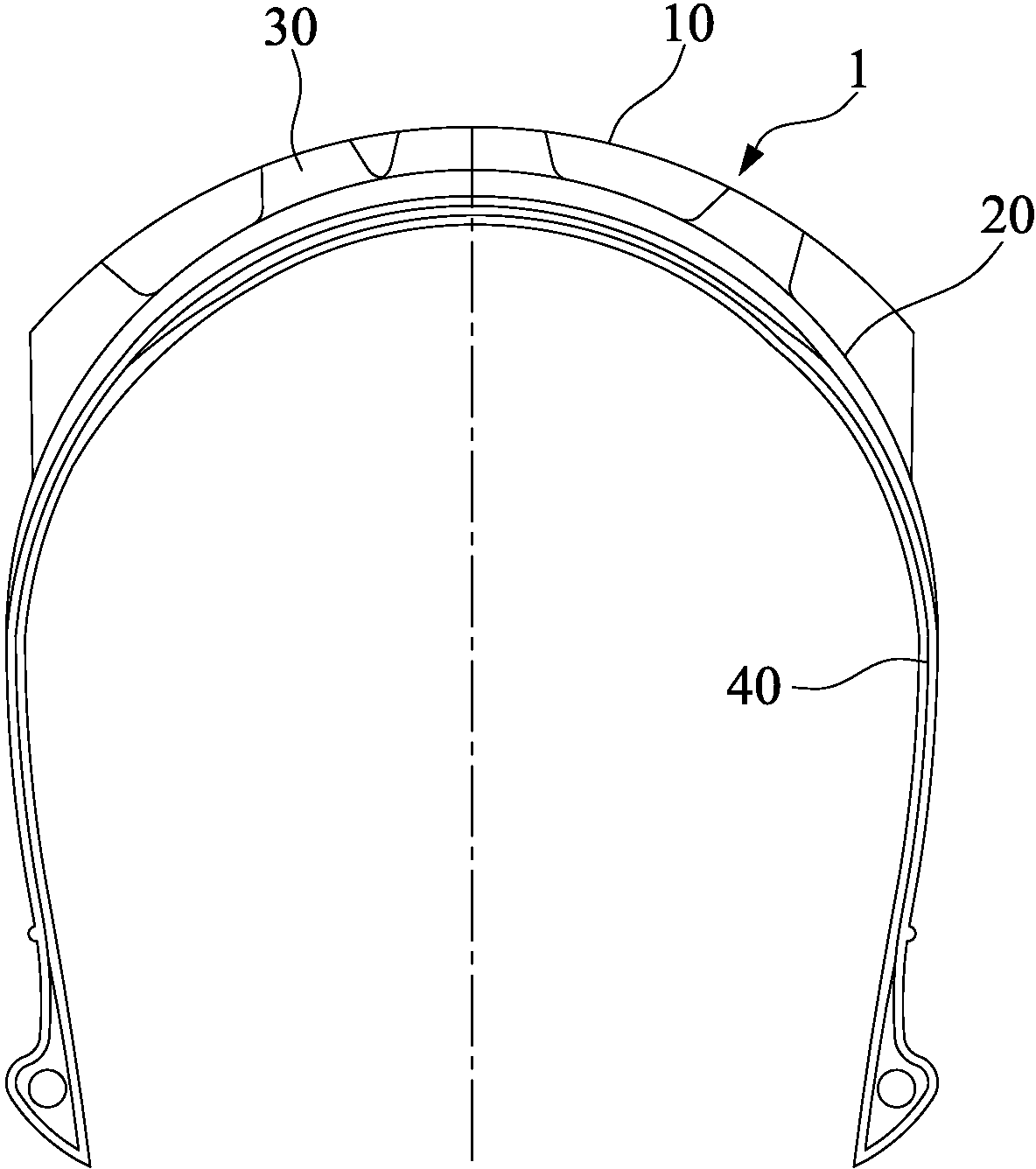

[0036] like Figure 1 to Figure 10 As shown, the present invention discloses a tread pattern and carcass structure of an off-road bicycle tire used on irregular road surfaces. exist figure 1 In , the vertical direction of the tire section is set as the tire radial direction, the lateral direction is set as the tire axial direction, and the single dotted line (tread centerline) represents the equatorial plane.

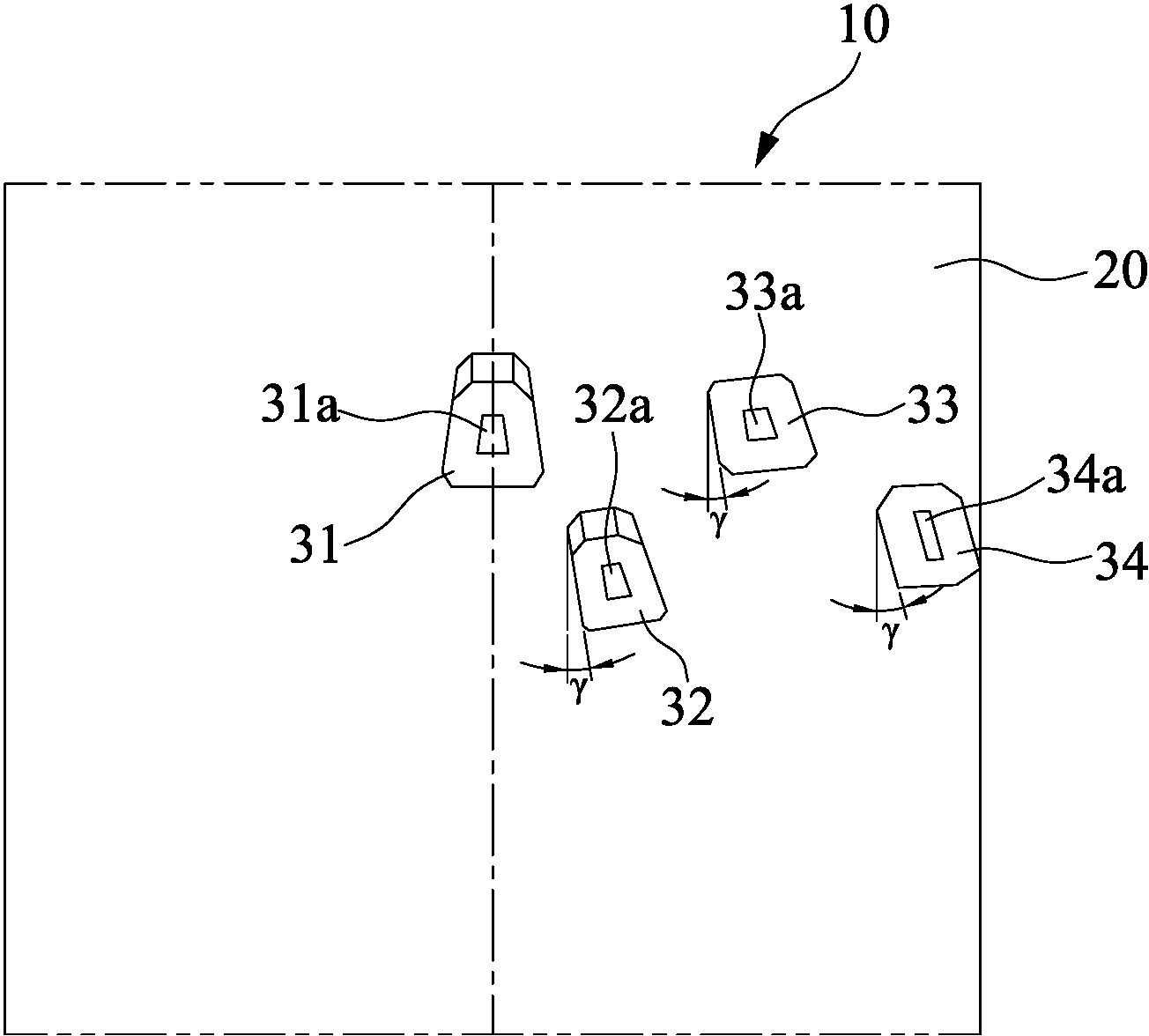

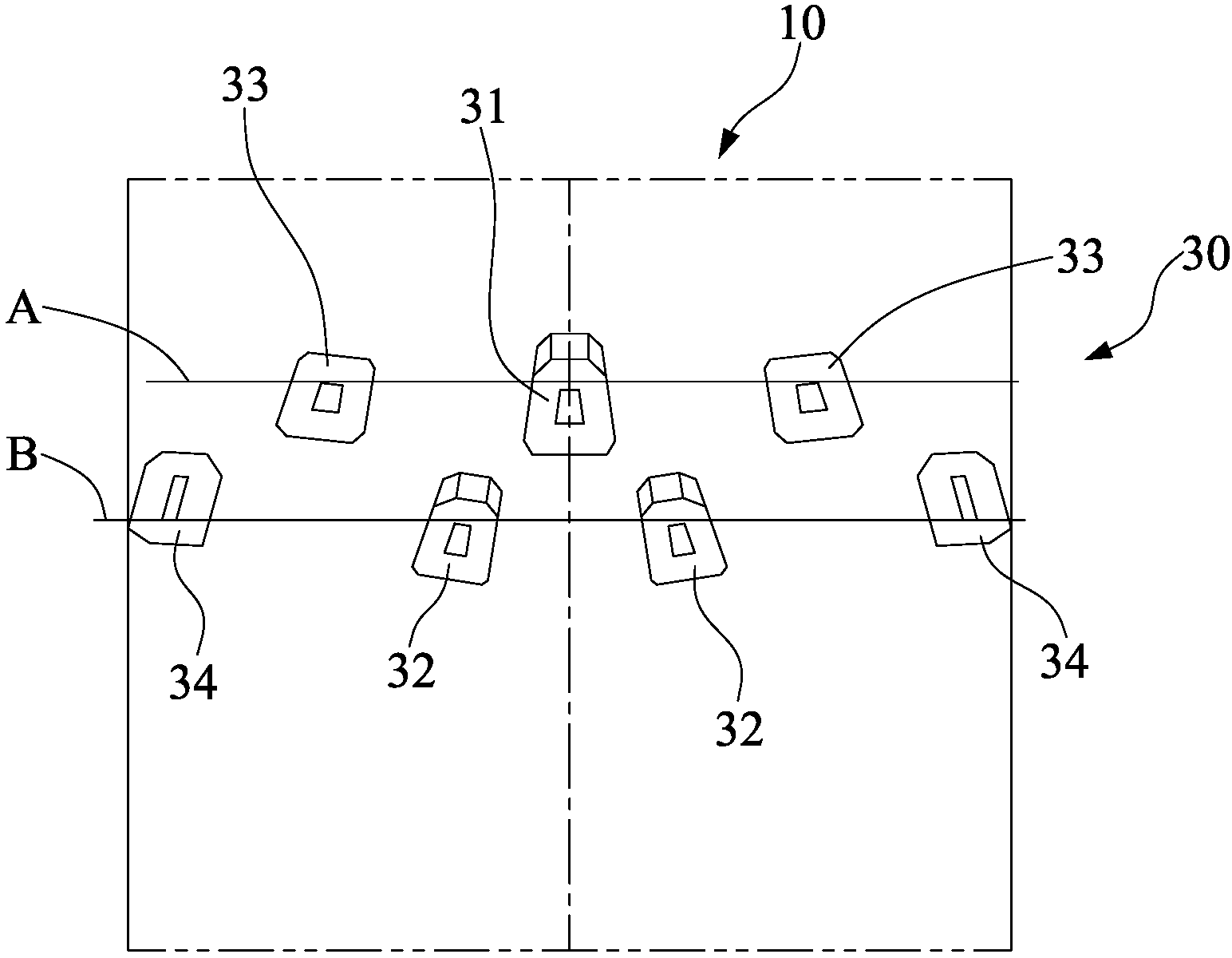

[0037] like figure 2 , image 3 As shown, a plurality of unit block groups 30 are evenly distributed on the tire tread 10, and each block group 30 includes an isosceles trapezoidal central main pattern block 31; The transitional blocks 33 in the same tire axial direction, that is, the central main block 31 and the transitional blocks 33 on both sides are arranged in alignment with each other in the axial direction of the tire to form part A arranged side by side. The transitional blocks 33 is roughly trapezoidal; in addition, between the middle main pattern block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com