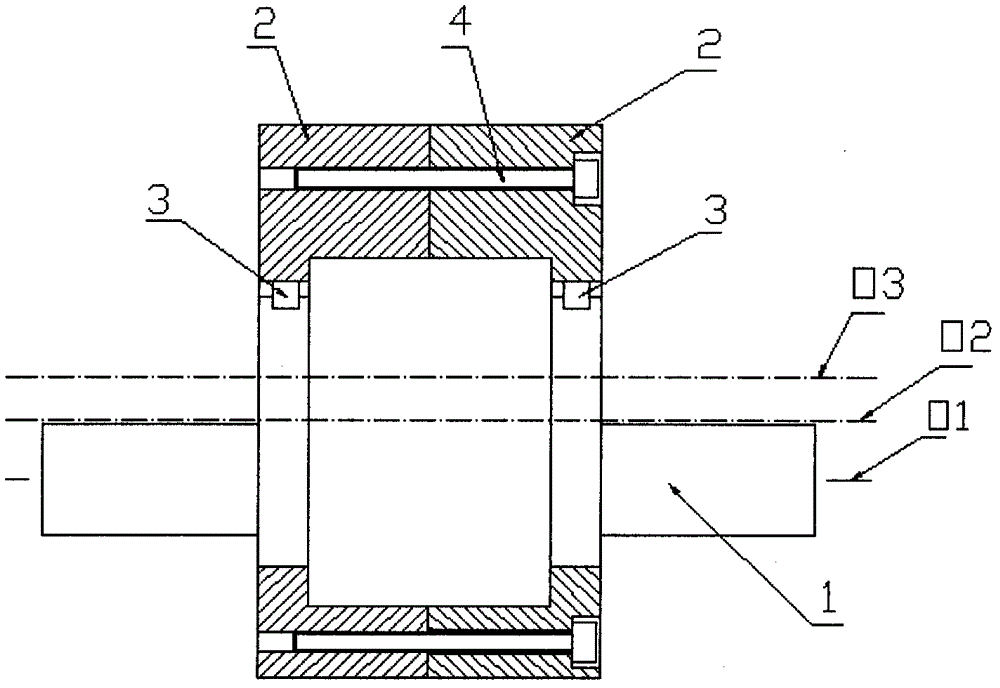

Structure of novel high-precision eccentric shaft

An eccentric shaft, high-precision technology, used in the structure of high-precision eccentric shafts and the structure of new high-precision eccentric shafts, can solve the problem of poor combining accuracy between eccentric sleeves and eccentric shafts, reducing the service life of parts, and easily causing large noises, etc. problems, to achieve the effect of not easy noise, eliminating gaps, and not easy to impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

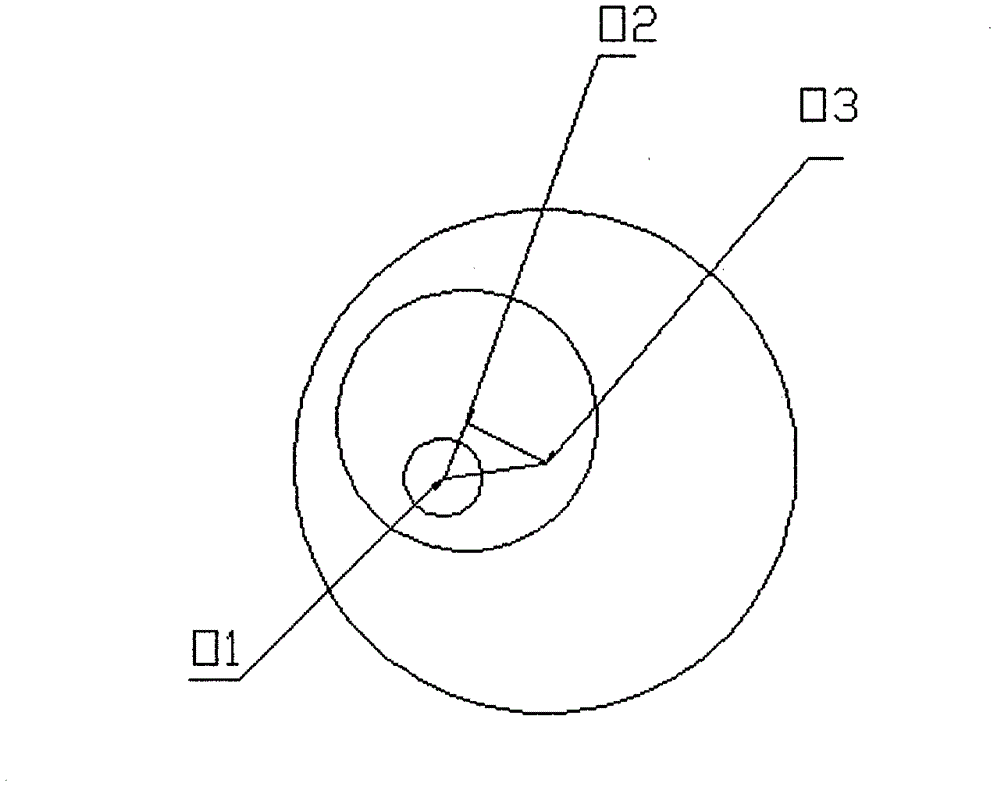

[0009] The eccentric shaft mechanism has two keys 3, and the two keys 3 are respectively installed in the key grooves at both ends of the eccentric shaft. The two eccentric sleeves 2 are connected together; when the eccentric distance needs to be adjusted, the bolt 4 is loosened, so that the left and right eccentric sleeves 2 are separated from the key 3, and the left and right eccentric sleeves 2 are rotated at the same angle relative to the eccentric shaft at the same time, due to the eccentric distance The size of O1-O3 is related to the size of the included angles O1, O2, and O3, so it can be realized only by adjusting the sizes of the included angles O1, O2, and O3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com