Unidirectional servo-type centrifugal clutch

A centrifugal clutch and self-energizing technology, which is applied in the field of clutches, can solve problems such as slippage of friction plates, inability to transmit power, and reduction of contact pressure, so as to achieve the effect of eliminating slippage and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

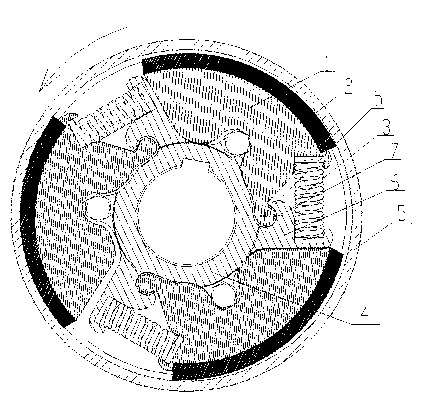

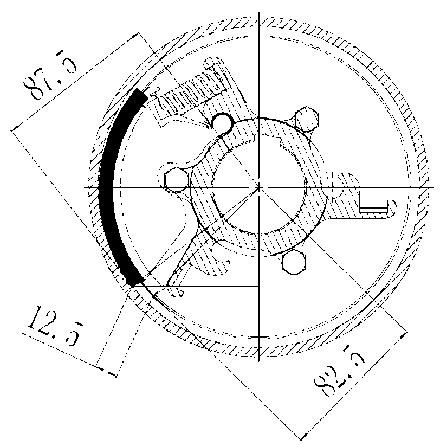

[0012] Embodiment 1, a kind of one-way self-energizing type centrifugal clutch, refer to figure 1 , the outer circumference of the active shell 4 is evenly provided with lugs 6, each lug 6 is provided with a joint socket 7, and the joint head 8 provided at one end of the centrifugal block 1 is movably installed in the joint fossa 7, and the spring 3 The two ends of the centrifugal block 1 and the bump 6 are respectively fixed on the outer side of the centrifugal block 1. The friction plate 2 is fixed, and the passive shell 5 is surrounded by the centrifugal block 1. When it is at rest, the spring 3 is in a compressed state. The centrifugal block 1 and the passive A gap is formed between the shells 5, and the number of the bumps 6 can be set as required. In this embodiment, three bumps 6 are used, which constitutes a structure of the present invention.

Embodiment 2

[0013] Embodiment 2, a kind of one-way self-energizing type centrifugal clutch, refer to figure 1 , on the basis of Embodiment 1, two springs 3 fixed on the centrifugal block 1 and the protruding block 6 are arranged side by side, and the others are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com