Gasoline engine base with underneath-type oil tank

A gasoline engine and fuel tank technology, applied in the field of gasoline engines, can solve the problems of short service life of the fuel tank, deformation or wear of the fuel tank, and poor stability, and achieve the effects of prolonging the service life, preventing deformation or wear, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

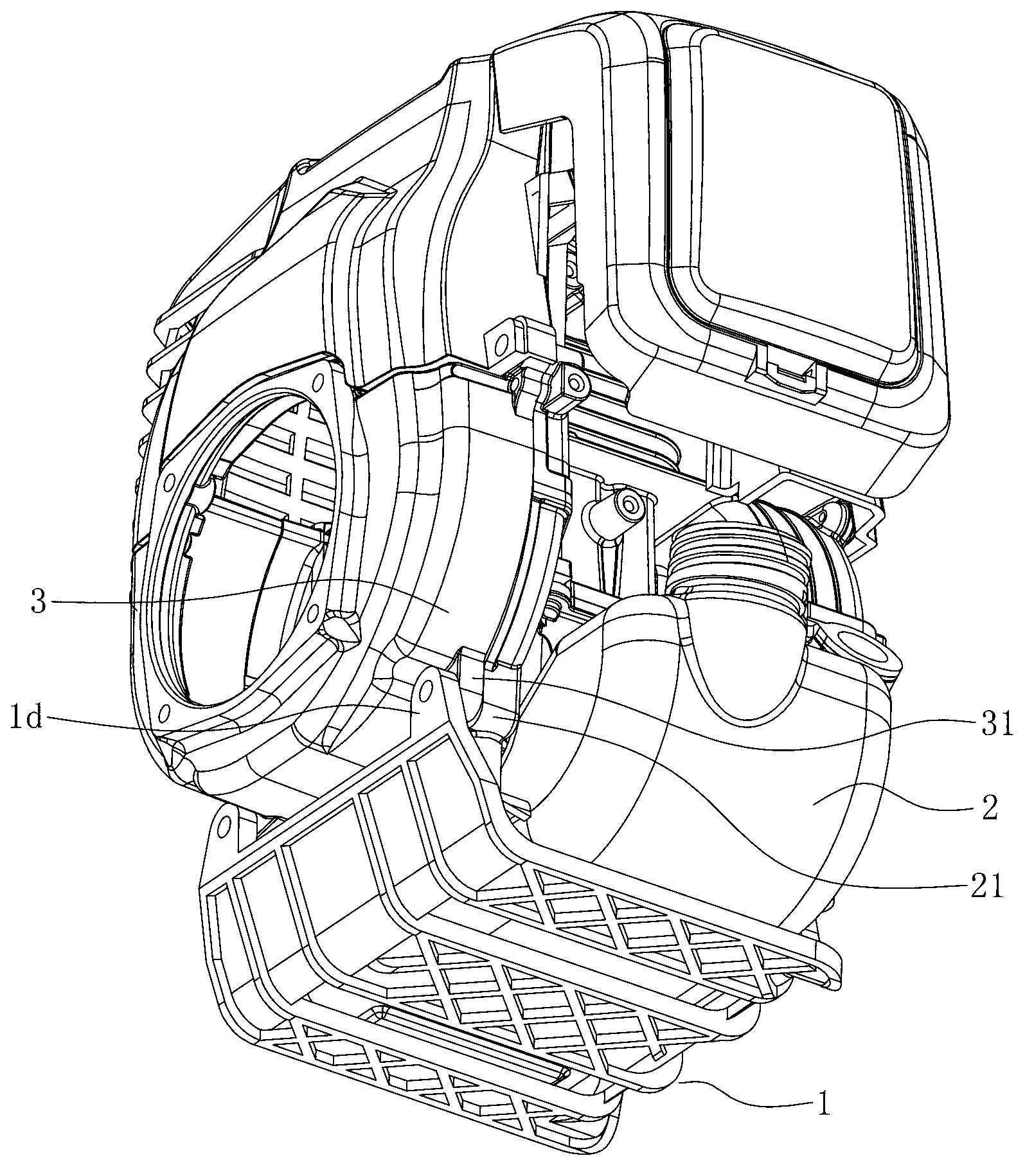

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

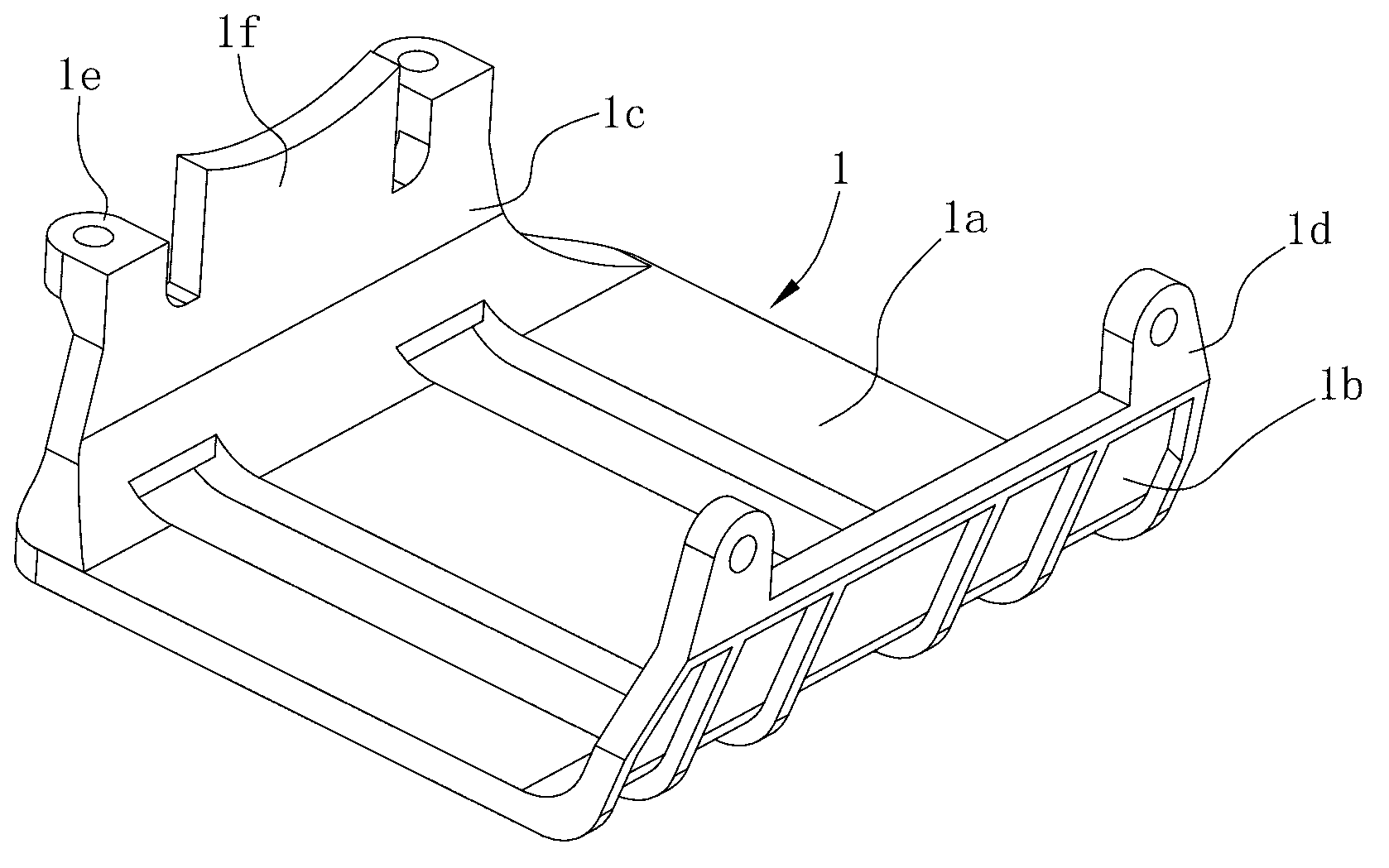

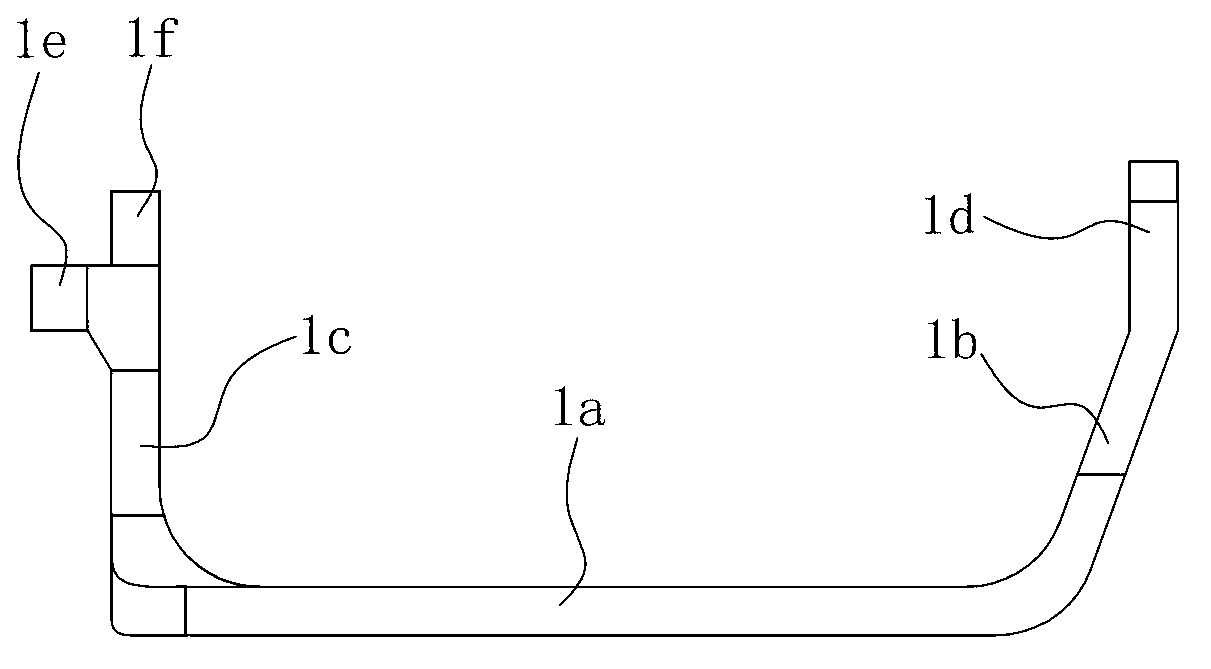

[0018] Such as figure 1 , figure 2 As shown, the present invention has a seat body 1, which is integrally formed by injection molding, and the material is preferably PP plastic. The seat body 1 is in the shape of a flat bottom "U" and is composed of a bottom plate 1a, a front side plate 1b and a rear side plate 1c. as one. There is an included angle of 110-120° between the front side panel 1b and the bottom panel 1a, and the specific size of the included angle can be determined according to actual needs. The left and right ends of the top of the front side plate 1b are symmetrically provided with lugs 1d, the lugs 1d are arranged in the vertical direction, the bottom of the lugs 1d is integrated with the top of the front side plate 1b, each lug 1d Via holes are opened along the front and rear directions.

[0019] Such as figure 1 , figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com