Air-conditioning outdoor unit condenser and air-conditioning outdoor unit with condenser

A technology for outdoor units and condensers of air conditioners, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of low-temperature heating capacity and low energy efficiency ratio in all seasons, and achieve the effect of increasing APF value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

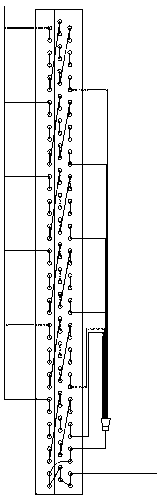

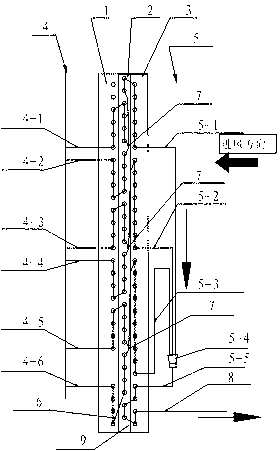

[0034] refer to figure 2 , an air conditioner outdoor unit condenser, including three rows of condenser components composed of aluminum foil fins and 40 U-shaped internal thread copper pipes, an inlet pipe assembly 4, an elbow 6, a U-shaped tee assembly, and an air outlet pipe assembly 5 And the total outlet pipe 8, the three rows of condenser assemblies are the inner row 1 located on the leeward side of the condenser, the middle row 2 and the outer row 3 located on the windward side of the condenser, wherein the intake pipe assembly 4 located on the leeward side of the condenser includes 6 branch routes, namely the first branch route 4-1, the second branch route 4-2, the third branch route 4-3, the fourth branch route 4-4, and the fifth branch route 4 -5. The sixth branch inlet 4-6, correspondingly, the air outlet pipe assembly 5 located on the windward side of the condenser includes three branch outlets, which are respectively the first branch outlet 5-1, the second branch ...

Embodiment 2

[0047] Such as image 3 As shown, the difference from Embodiment 1 is the arrangement of three process branches,

[0048] Such as Figure 7 As shown, the flow arrangement of the first flow branch is as follows:

[0049] The first branch route 4-1 connects the two U-shaped internal thread copper pipes located in the inner row 1 of the condenser from bottom to top, connects to the middle row 2 through the elbow 6, and connects the three U-shaped internal threads of the middle row 2 The copper pipes are connected from top to bottom to form a " ”-shaped process, the second branch route 4-2 connects the two U-shaped internal thread copper pipes located in the inner row 1 of the condenser from top to bottom, connects to the middle row 2 through the elbow 6, and connects the middle row 2 Two U-shaped internal threaded copper pipes are connected from bottom to top to form a "U"-shaped process. The first and second branch routes 4-1 and 4-2 are aggregated into one road through the ...

Embodiment 3

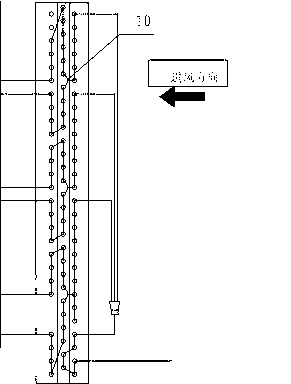

[0055] Such as Figure 4 As shown, the only difference from Embodiment 1 is that the third branch approach 4-3 and the fourth branch approach 4-4 in the second process branch are aggregated into one road through the claw-shaped tee 10 in the middle row, and the aggregate To the outer row 3, the four U-shaped internal thread copper pipes of the outer row 3 are connected from bottom to top, and finally aggregated to the second branch outlet 5-2.

[0056] The processes of the first and third process branches are the same as those of the first and third process branches in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com