Picture frame structure of heavy-calibre combined lens

A combined lens, large-diameter technology, used in instruments, installation, optics, etc., can solve the problems of difficulty, small center deviation of optical components, and high processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

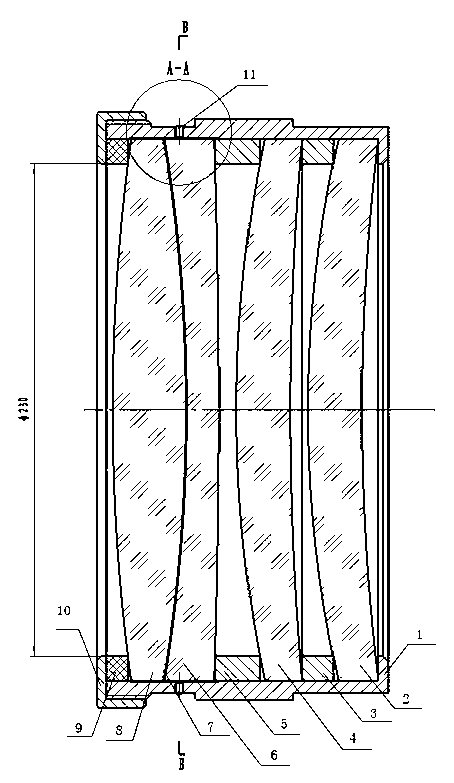

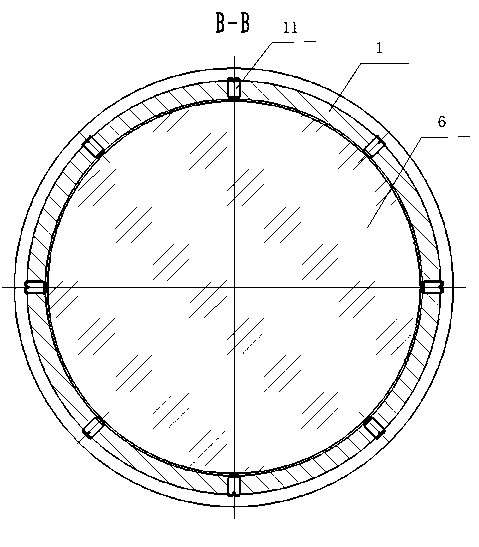

[0022] The structure of the present invention will be described below by taking the picture frame of four large-diameter combined lenses as an example. In this embodiment, the combined lens has a diameter of 250 mm and a clear aperture of 230 mm.

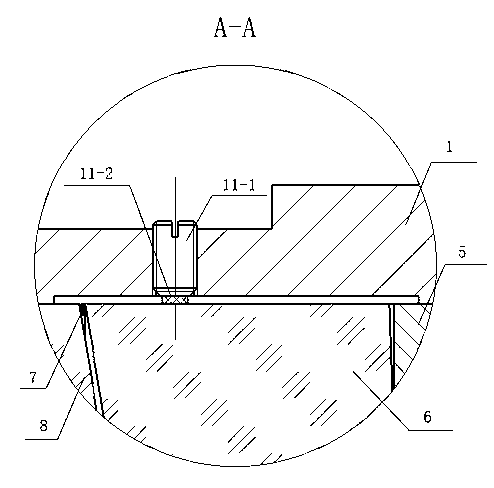

[0023] see first figure 1 , figure 1 It is the front view of the picture frame structure embodiment of the large-caliber composite lens of the present invention, which embodiment consists of picture frame 1, lens one 2, spacer one 3, lens two 4, spacer two 5, lens three / adjustable lens 6, spacer Ring 3 7, lens 4 8, washer 9, thread pressure ring 10, and adjustment screw structure 11. The combined lens of this embodiment is four circular lenses, and its feature is that the adjustment screw structure 11 is added to the picture frame 1. , the positional relationship of the above components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com