High-power IGBT drive circuit

A high-power, high-resistance technology, applied in the field of high-power IGBT drive circuits, can solve the problems of low drive power, low switching frequency, and high price, and achieve the effect of strong drive capability and high switching frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0007] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

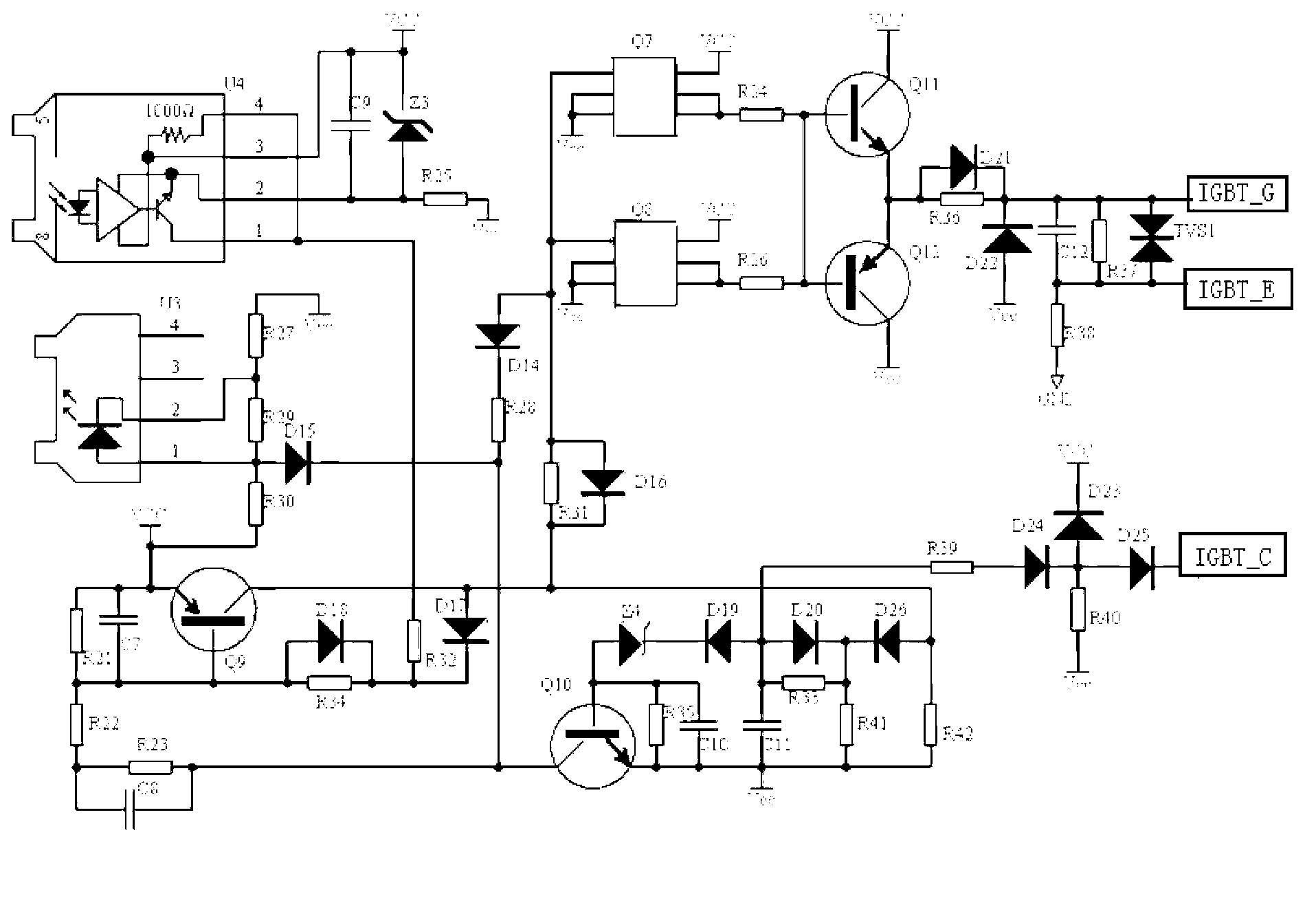

[0008] Such as figure 1 As shown, the high-power IGBT drive circuit of the present invention includes a seventh integrated transistor array Q7, an eighth integrated transistor array Q8, a ninth transistor Q9, a thirteenth transistor Q10, an eleventh transistor Q11, and a twelfth integrated transistor array Q7. Transistor Q12, 22nd resistor R22, 23rd resistor R23, 24th resistor R24, 26th resistor R26, 28th resistor R28, 31st resistor R31, 30th resistor Three resistors R33, thirty-ninth resistor R39, forty-second resistor R42, fourteenth diode D14, twenty-first diode D21, twenty-fourth diode D24, twenty-fifth diode The tube D25, the twenty-sixth diode D26, the eighth capacitor C8, the tenth capacitor C10, the eleventh capacitor C11, the fourth voltage regulator Z4, and the ninth transistor Q9 are c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap