High-power pulse smoke sprayer

A fog machine, high-power technology, applied in the device of capturing or killing insects, application, animal husbandry, etc., can solve the problems of not being able to meet various spraying operations, single operation mode, slow spraying speed, etc., and achieve coverage Wide range, long spraying range and enhanced spray pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

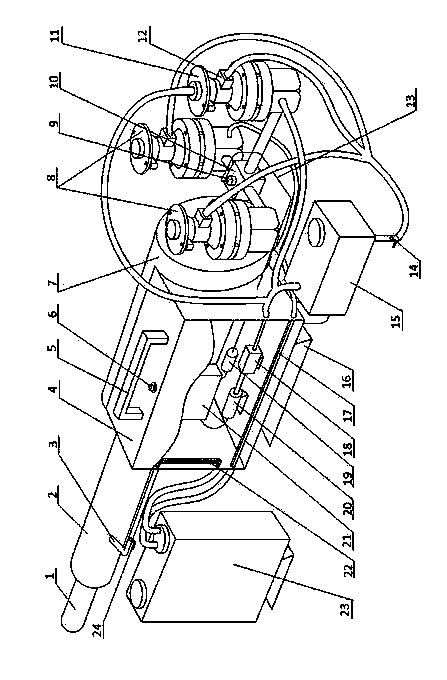

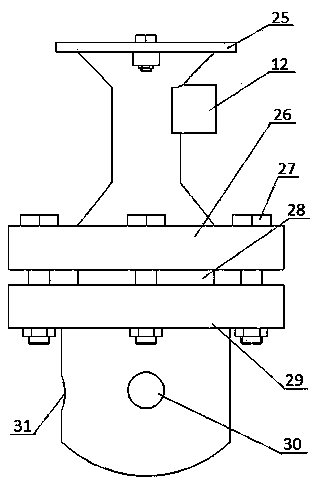

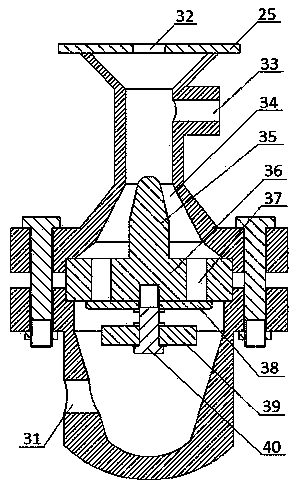

[0016] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention relates to a high-power pulsed fog machine, which is provided with a power supply system, an air supply system, an oil supply system, a carburetor system, an ignition system, and an injection system. A power supply 21 is provided, and the power supply 21 is controlled by a switch 6 located on the top of the chassis. The top of the chassis is provided with a handle 5 and the bottom is provided with a base 16; Connected to the power supply 21, the main shaft on the motor 20 drives the air pressure pump 18, and the exhaust holes on the air pressure pump 18 are respectively connected with the top of the oil tank 15 and the main carburetor 11 through pipes; the oil supply system is an oil tank installed outside the chassis. 15. The bottom of the fuel tank 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com