Belt-type tempering device for plastic floor

A technology of plastic floor and front conveyor belt, applied in the field of heat treatment equipment, can solve the problems of heavy boiler safety operation management, low boiler thermal efficiency, increase production cost, etc., and achieves convenient electric heating, stable tempering quality, and easy temperature adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

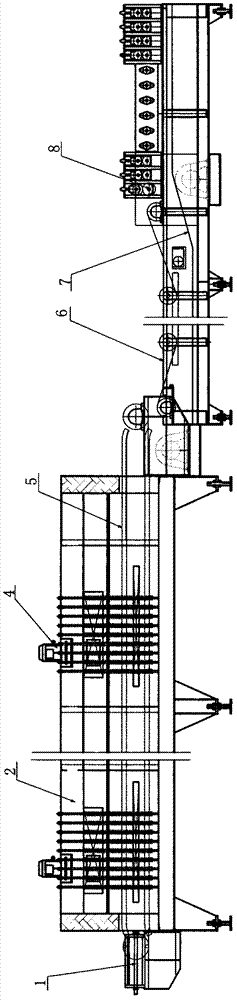

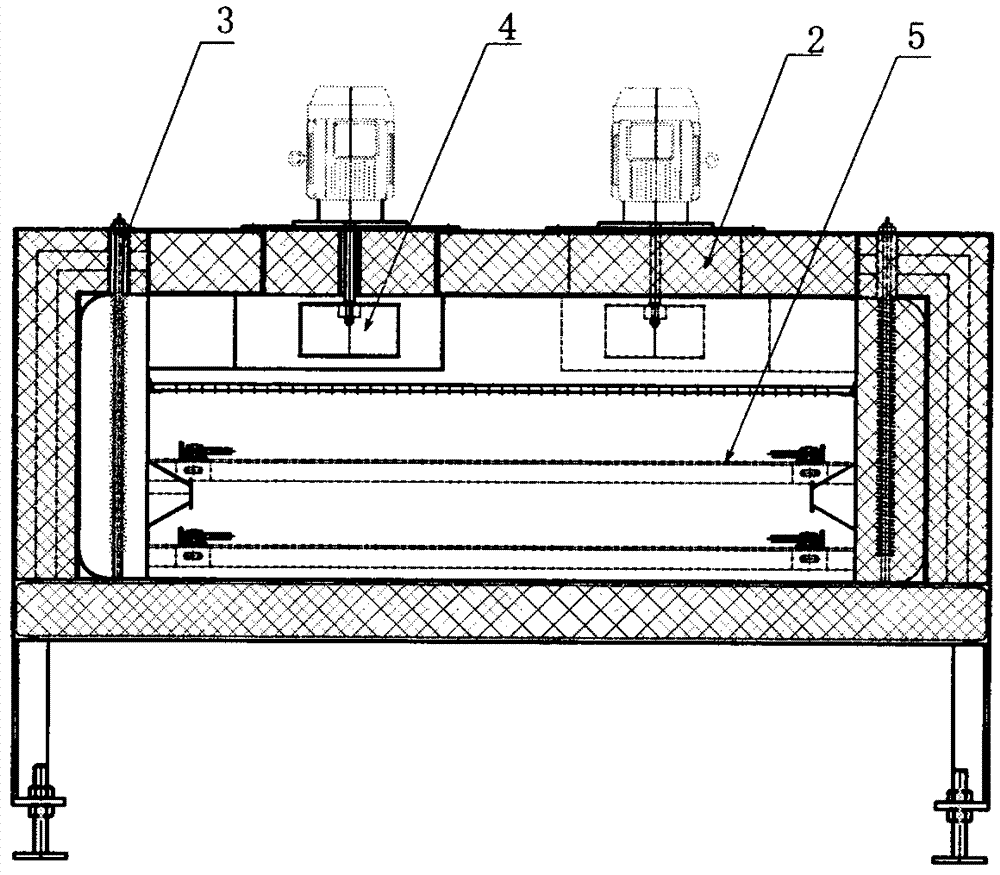

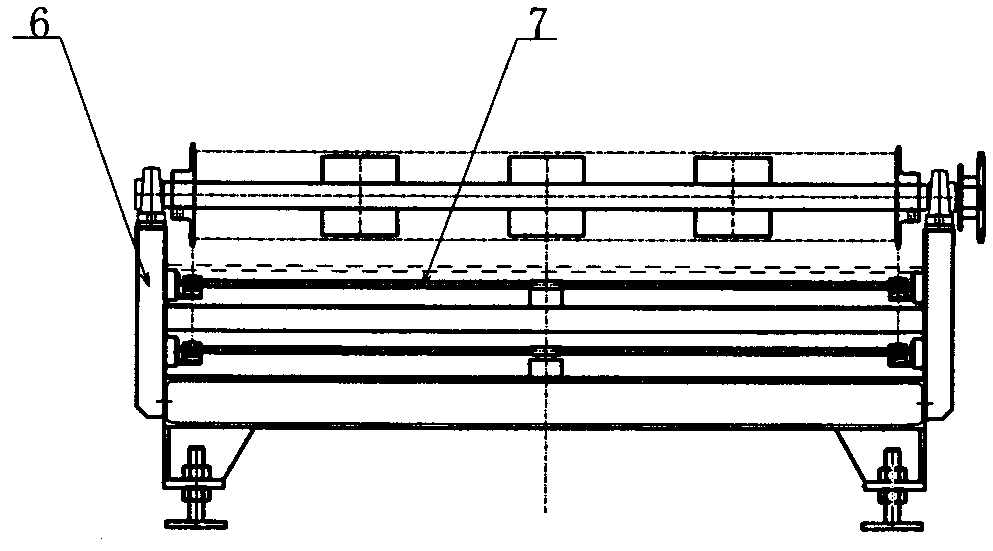

[0018] figure 1 The plastic floor belt type tempering machine shown is composed of sequentially connected heating device, water cooling device and water suction device. The front heating device includes a feeding table, a drying room 2, a heater 3, a hot air circulation machine 4 and a front conveyor belt 5. The water cooling unit starts at the outlet of the heating unit, which consists of image 3 The shown straight strip water tank 6 and the built-in rear conveyor belt 7 form the straight-ahead mechanism in water. The drying room 2 is a rectangular body made of thermal insulation material, with a total length of 8m, and is divided into 8 sections connected in the same direction in the same direction. Afterwards, the heater 3 and the hot air circulation machine 4 are uniformly arranged on the left side of the odd-numbered section ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap