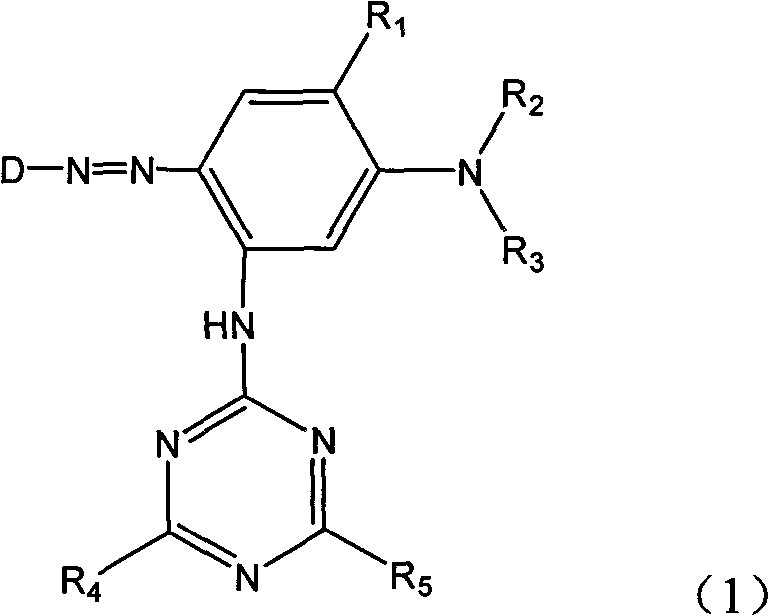

Triazine structure contained dye

A disperse dye and monoazo technology, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of difficult dyeing depth, poor washing fastness, etc., and achieve excellent moisture resistance, good temperature dependence, sublimation Good fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

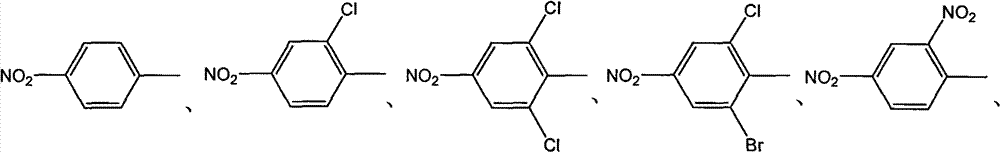

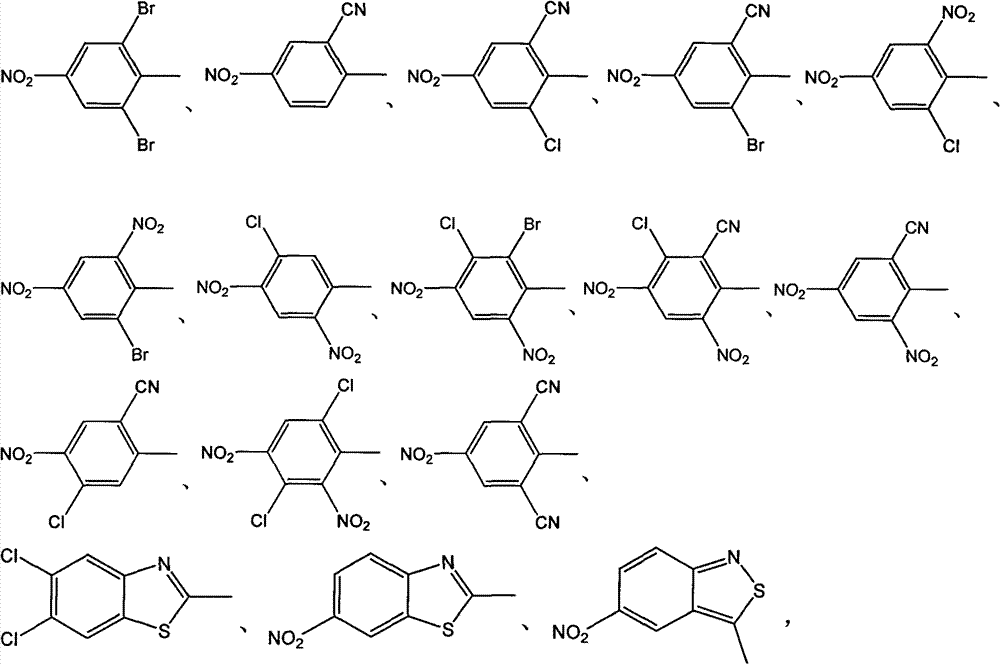

Method used

Image

Examples

Embodiment 1

[0025] Add 50 milliliters of sulfuric acid in the flask, add 34.5 grams of o-chloro-p-nitroaniline at room temperature, add 26 grams (100%) of nitrosyl sulfuric acid, and react with diazonium for 4 hours. After the reaction is completed, add 20 milliliters of sulfuric acid, 900 grams of In the mixture of ice water and 62 grams of compounds shown in formula (2),

[0026] Formula (2)

[0027] After the addition, continue to react for 2 hours, add 1000 milliliters of water, slowly rise to 60 ° C and keep warm for 2 hours, cool, and suction filter to obtain the monoazo compound containing triazine structure shown in formula (3):

[0028] Formula (3)

[0029] The polyester fiber is dyed to obtain a red dyed product with excellent fastness properties.

Embodiment 2

[0031] Add 50 ml of sulfuric acid to the three-necked flask, add 52.4 grams of 2,4-dinitro-6-bromoaniline at room temperature, add 26 grams of nitrosyl sulfuric acid (100%), and react with diazonium for 4 hours. After the reaction is completed, add In the mixture of 20 milliliters of sulfuric acid, 900 grams of ice water and 69 grams of compounds shown in formula (4),

[0032] Formula (4)

[0033] After the addition, continue to react for 2 hours, add 1000 milliliters of water, slowly rise to 60 ° C and keep warm for 2 hours, cool, and suction filter to obtain the monoazo compound containing triazine structure shown in formula (5):

[0034] Formula (5)

[0035] The polyester fiber is dyed to obtain a blue dyed product with excellent fastness properties.

Embodiment 3

[0037] Add 50 ml of sulfuric acid into a three-necked flask, add 26 grams of nitrosyl sulfuric acid (100%), add 41.6 grams of 2,4-dinitro-6-cyanoaniline below 10°C, and react with diazonium below 10°C for 4 hours , after the completion of the reaction, add in the mixture composed of 20 milliliters of sulfuric acid, 900 gram of ice water and 74 gram of compound shown in formula (6),

[0038] Formula (6)

[0039] After the addition, continue to react for 2 hours, add 1000 milliliters of water, slowly rise to 80° C. and keep warm for 1 hour, cool, and suction filter to obtain a monoazo compound containing a triazine structure as shown in formula (7):

[0040] Formula (7)

[0041] The polyester fiber is dyed to obtain a blue dyed product with excellent fastness properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com