Biomass gasification catalytic cracking process and integral gasification catalytic reactor

A catalytic cracking and biomass technology, applied in the field of biomass energy utilization, can solve the problems of gas being burned and easy to block gas pipelines, etc., to avoid sensible heat loss, overcome complex process route problems, and overcome fine carbon particles or flying Difficult to separate gray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

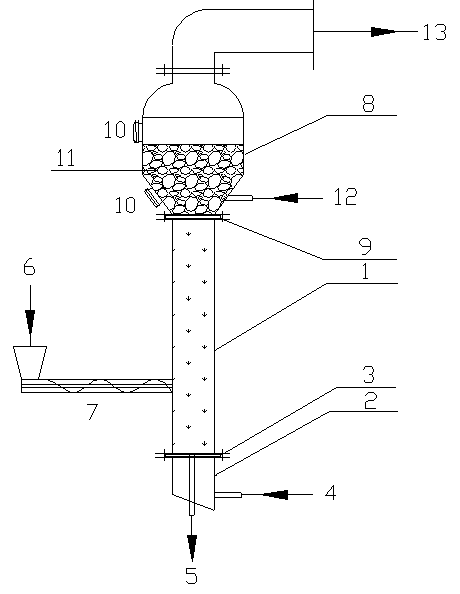

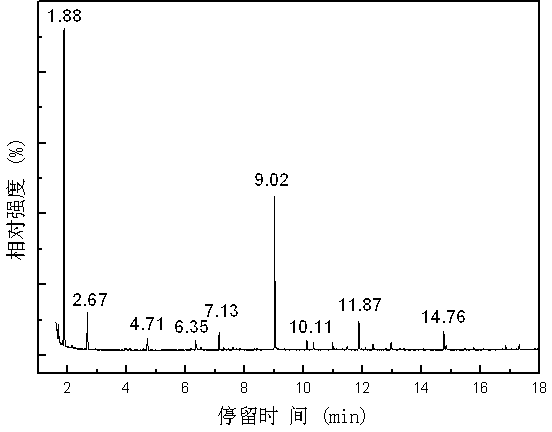

[0020]Biomass wood powder is fed into the biomass gasification section 1 of the lower part of the integrated biomass gasification catalytic reactor through the biomass feeding device 7, and the primary gasification agent (air) 4 enters the equal pressure air chamber 2, and then passes through the air distribution The plate 3 enters the biomass gasification section 1, and by controlling the feed rate and the amount of the primary gasification agent 4, when the standard superficial cross-sectional flow velocity of the primary gasification agent in the gasification section is 0.3-0.5m / s, the biomass The temperature of the substance gasification section is controlled at 600-750 for oxidation-reduction reaction to generate flammable gas (referred to as gas) accompanied by the generation of tar, and the generated flammable gas entrains tar and incompletely reacted charcoal Particles flow upwards, through tar catalytic cracking section 8, (cobalt-based composite catalyst is housed in ...

Embodiment 2

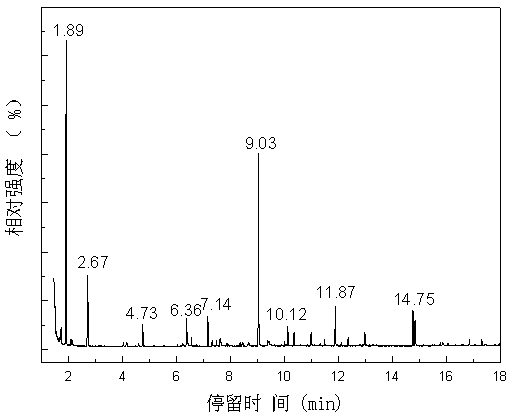

[0024] The biomass chaff is fed into the biomass gasification section 1 at the lower part of the integrated biomass gasification catalytic reactor through the biomass feeding device 7, and the primary gasification agent (air) 4 enters the equal pressure air chamber 2, and then passes through the air distribution The plate 3 enters the interior of the biomass gasification section 1, and by controlling the feed rate and the amount of the primary gasification agent 4, the primary gasification agent can be used when the standard superficial cross-sectional flow velocity of the gasification section is 0.3-0.5m / s , under the temperature control of the biomass gasification section, oxidation-reduction reaction occurs at 600-750 ℃, and flammable gas is generated, accompanied by tar formation, and the flammable gas generated entrains tar and incompletely reacted carbon particles to flow upward. After the tar catalytic cracking section 8, under the action of the tar cracking catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com