A device and method for in-situ catalytic gasification of biomass to produce hydrogen-rich gas

A catalytic gasification and biomass technology, applied in the direction of granular/powdered fuel gasification, chemical recovery, etc., can solve difficult problems, difficult to control the air volume of secondary gasification agent, and large amount of heat carrier used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

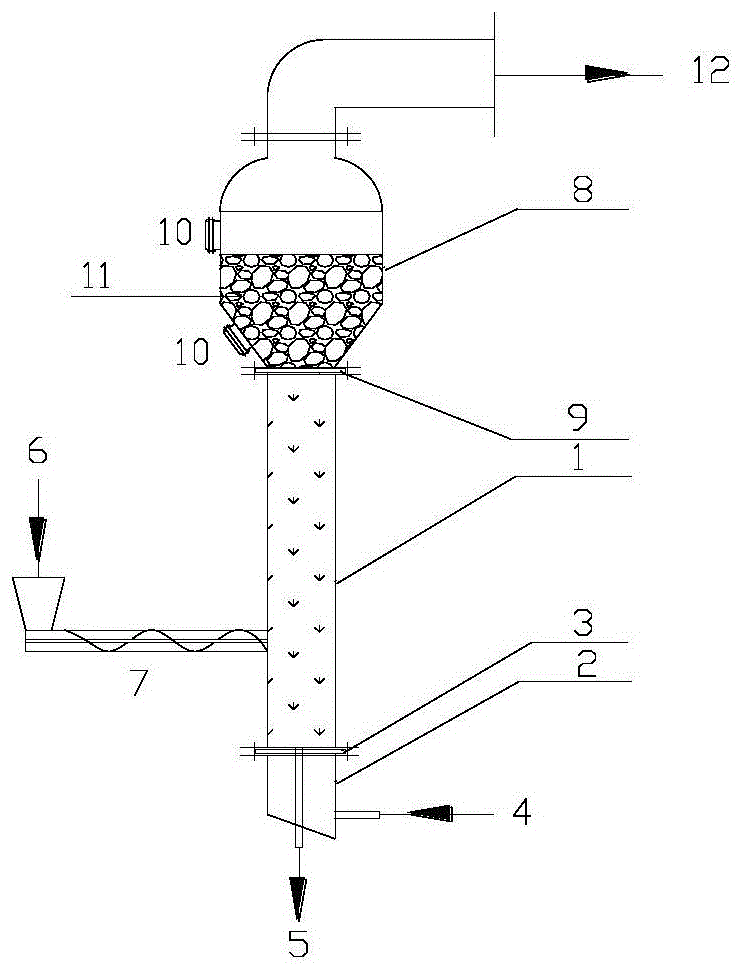

[0029]Biomass wood powder with a particle size of 5 mm and nickel catalyst mixture 6 with a particle size of 5.31 μm and 2% of the wood powder mass are fed into the lower fluidized section 1 of the biomass in-situ catalytic gasification reactor through a screw feeding device 7 , the gasification medium is air, which enters the equal-pressure air chamber 2 through the gasification agent inlet 4, and then enters the interior of the fluidization section 1 through the air distribution plate 3, and controls the feeding rate and the amount of the gasification medium so that the air-fuel ratio is Under the condition of 0.23, the oxidation-reduction reaction occurs in the biomass gasification section at 600°C-750°C, generating flammable gas and accompanied by the formation of tar, which undergoes in-situ catalytic cracking under the action of the catalyst to form small molecules Gas, hydrogen-rich combustible gas entrained with fly ash, as well as incompletely reacted biomass particles...

Embodiment 2

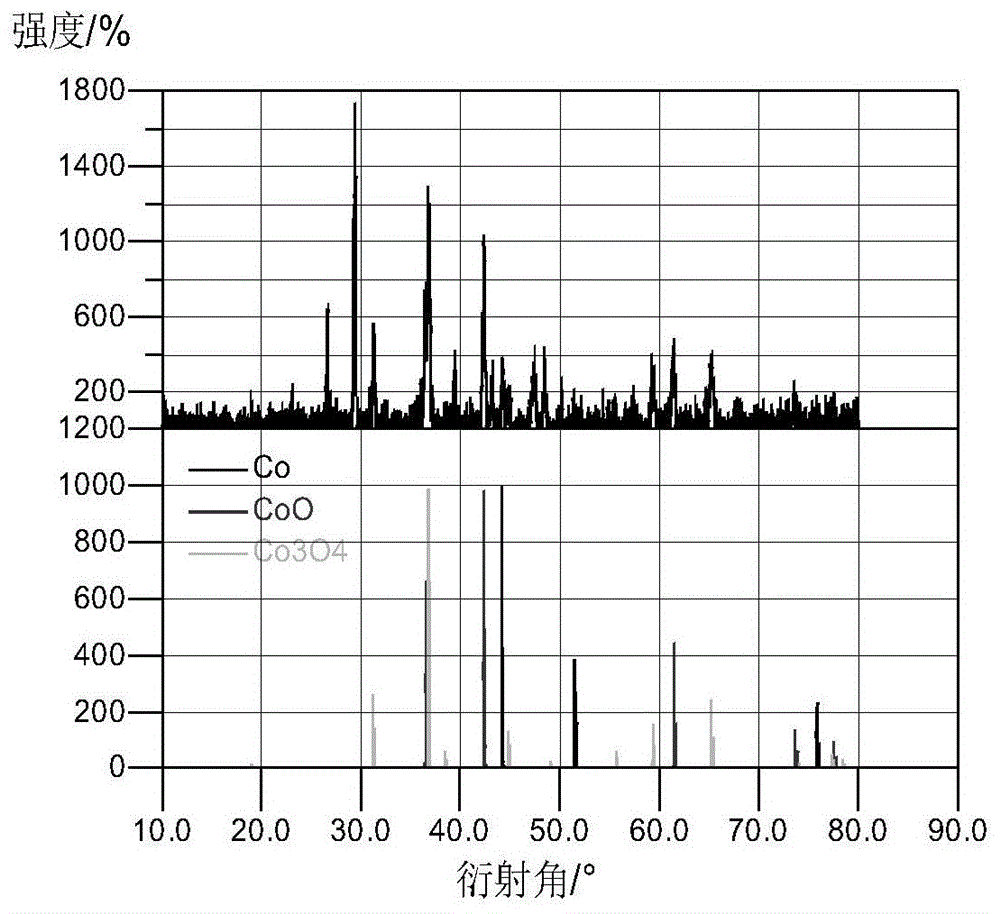

[0031] The 8mm biomass chaff and the cobalt catalyst 6 with 2% of the chaff mass and a particle size of 6 μm are fed into the lower fluidization section 1 of the biomass in-situ catalytic gasification reactor through the screw feeding device 7, and the air gasification medium passes through The gasification agent inlet 4 enters the equal pressure air chamber 2, and then enters the interior of the biomass fluidization gasification section 1 through the air distribution plate 3. By controlling the feeding rate and the amount of gasification medium added, the air-fuel ratio is 0.23, and the biomass In the material gasification section, oxidation-reduction reactions occur at 600°C-750°C, and flammable gases are produced, accompanied by the generation of tar. Under the action of the catalyst, the tar undergoes in-situ catalytic cracking to generate small molecule gas, which is hydrogen-rich and flammable. The gas entrains fly ash, as well as incompletely reacted carbon particles and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com