Wall thickness detecting device and wall thickness detecting method for transparent and semitransparent glass bottles

A detection device and glass bottle technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of inaccurate bottle wall thickness, affecting identification, and inability to accurately measure the 41-pixel distance of the light spot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

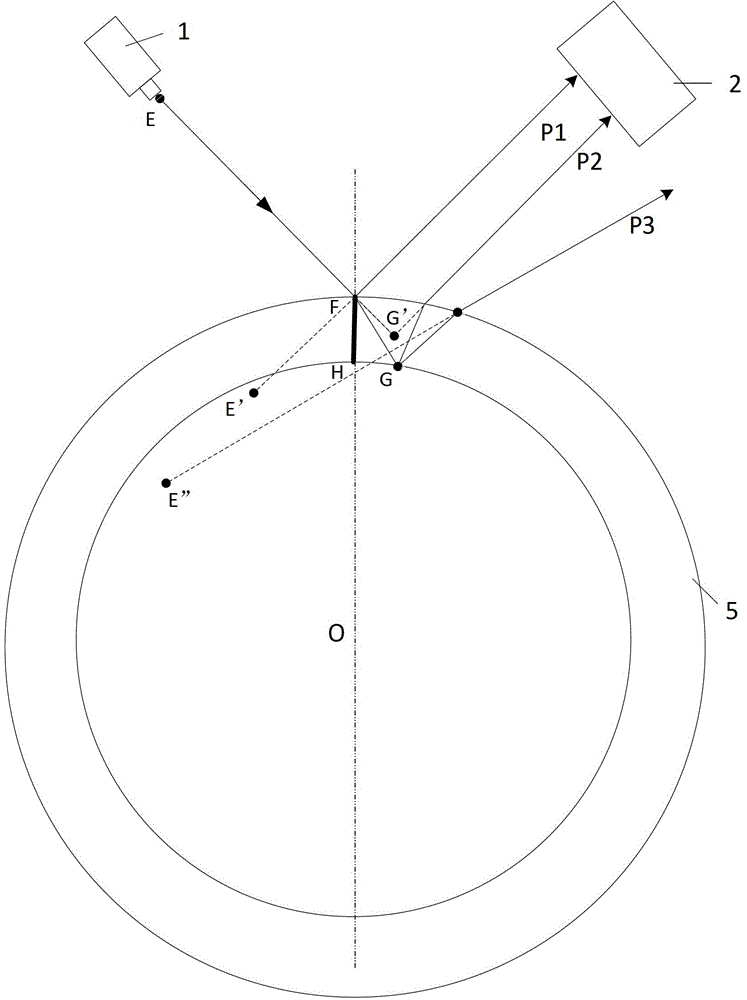

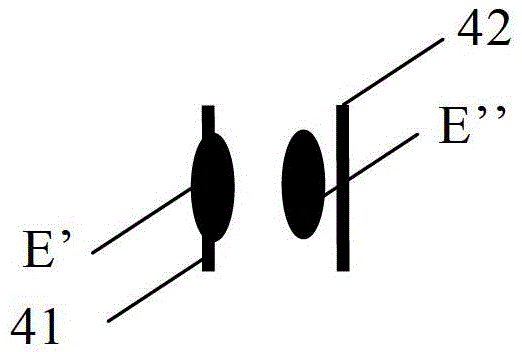

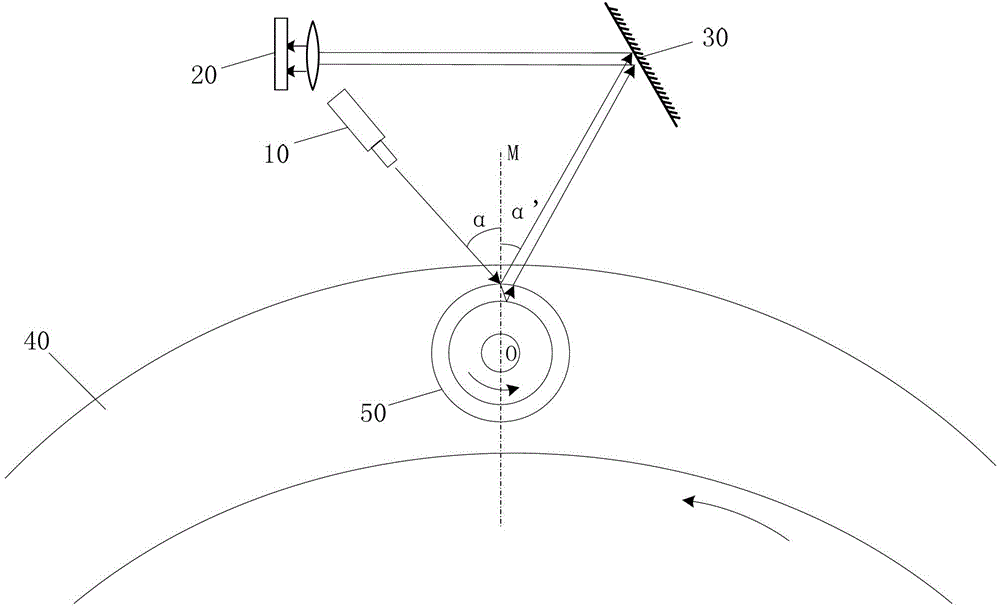

[0023] Such as Figure 3 to Figure 5 As shown, the present invention proposes a transparent and translucent glass bottle wall thickness detection device, which includes a laser emitter 10, an image pickup device, and the laser emitter 10 and the image pickup device are relative to the glass bottle 50 to be detected. Detection point (the wall thickness at this detection point position is the wall thickness to be measured) 60 normal line MO (point O is the cross-sectional center of the glass bottle to be detected, and normal line MO is the outer wall where the light is located at the detection point 60 The normal line when reflecting on the upper surface) is correspondingly set, wherein: the emitting end of the laser emitter 10 faces the detection point 60 on the glass bottle 50 to be detected and the central axis 11 of the emitting end of the laser emitter 10 is in a horizontal plane An acute angle β, the angle α between the central axis 11 of the emitting end of the laser emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com