Non-contact type human body height measuring method based on optical imaging

A non-contact technology of human body height measurement, which is applied in the field of human body height measurement, can solve the problems of difficult flexible application, inflexibility, and large limitations, and achieve the effect of high concealment, fast speed, and flexible measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

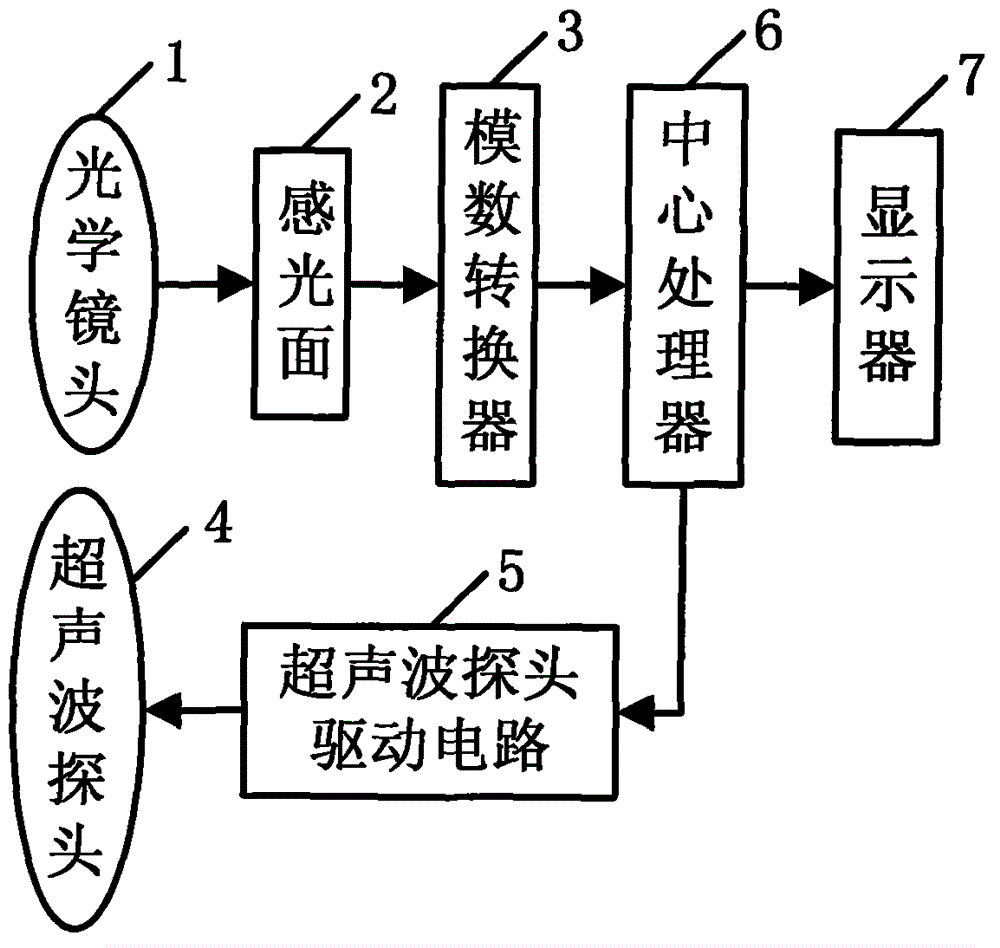

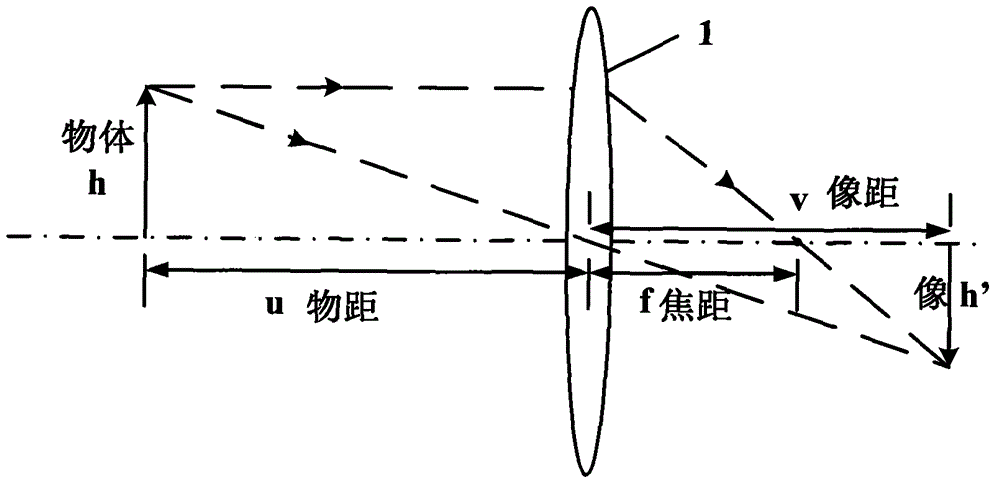

Method used

Image

Examples

Embodiment 1

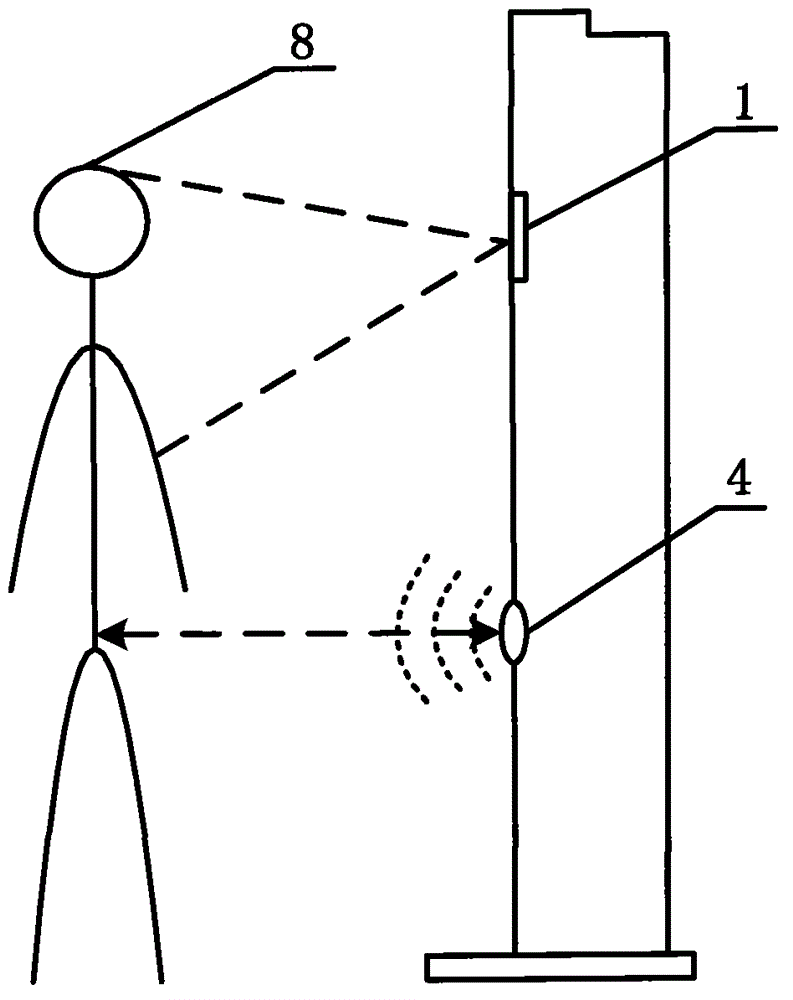

[0041] In some application occasions, it is necessary to take a relatively clear image of the human body face, the optical lens 1 is installed at a position corresponding to the upper body of the human body 8, and the photosensitive surface 2 can receive the image of the upper body of the human body including the entire head. see image 3 As shown, in this embodiment, the central axis of the optical lens 1 is placed along the horizontal direction, and the optical lens 1 and the ultrasonic probe 4 are located in the same vertical plane. In this case, a reference object 9 must be introduced, and the position of the reference object 9 and its image on the imaging surface shall be calibrated once during the production process of the non-contact measuring device. During normal use, only measurement The actual height of the human body 8 can be obtained by calculating the distance between the top of the head of the image of the human body 8 and the image of the reference object 9 . ...

Embodiment 2

[0052] In practical applications, in some occasions, the optical lens is installed higher than the top of the human head, and the axis of the optical lens 1 cannot be placed along the horizontal direction, but placed at a certain angle with the horizontal plane, see Figure 6 As shown, the center points of the ultrasonic probe 4 and the optical lens 1 may or may not be located in the same vertical plane. When the center point of the ultrasonic probe 4 and the optical lens 1 are not in the same vertical plane, the offset needs to be measured during the calibration process, and the offset is used when the central processor 6 reads the data of the ultrasonic probe 4 Just make corrections.

[0053] If the center point of the ultrasonic probe and the optical lens are not in the same vertical plane, it is necessary to calculate the distance u from the human body to the optical lens and the distance u from the reference object to the optical lens 1 Correction: When the ultrasonic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com