Environment-friendly type fine-denier composite filament stripe-derivative mixed fabric and weaving method thereof

A composite silk, environmentally friendly technology, applied in the direction of embossed fabrics, textiles and papermaking, fabrics, etc., can solve the problems of fineness, lightness, luster, environmental protection gap, etc., to enhance wearing comfort, promote progress, and good environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0015] The weaving method of environment-friendly fine-denier composite silk stripe transformation interweaving cloth is specifically:

[0016] (1) Use 20D / 12F nylon matte FDY as the warp thread, and 20 / 26 polyester composite yarn as the weft thread for interweaving. The composite yarn is obtained by compounding fine denier polyester 20FDY and 26DPOY.

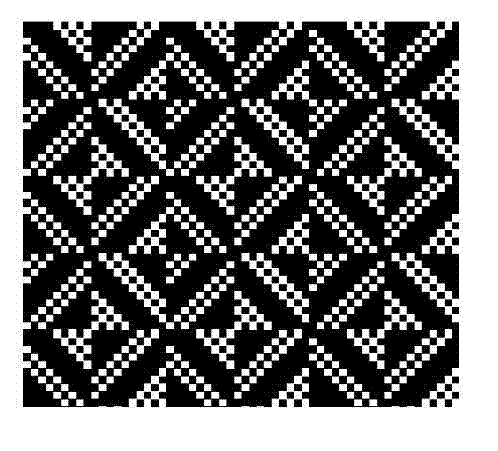

[0017] (2) Design the 20*20 new changing weaving pattern, through the alternating change of warp and weft floating length, the striped and changing texture of the fabric appearance is formed, with a strong three-dimensional effect.

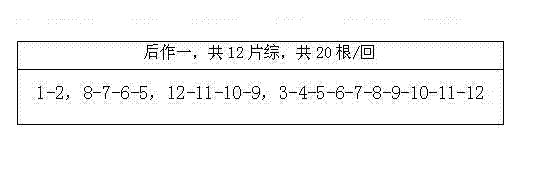

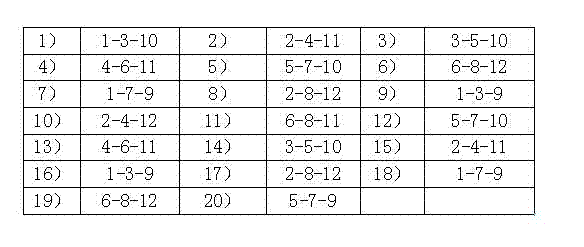

[0018] (3) The design of the weaving process is as follows: total warp: 13350 reeds, 25# steel reeds are used for 3 reeds, the reed width of the upper machine is 178cm, the weft density of the upper machine is 52 pcs / cm, and the sides are on the same ground; heavy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com