Dual-layer dual-face eyelet fabric and weaving method thereof

A mesh cloth, double-sided technology, applied in textiles and papermaking, fabrics, textiles, etc., can solve single problems, achieve the effect of improving grades, improving hand feeling, and improving anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0015] The weaving method of double-layer double-sided mesh cloth: specifically:

[0016] (1) Use 75D / 36F glossy polyester FDY plus 8 twists / S as the warp, 80S / 1 polyester viscose blended yarn 55 / 45 and 75D / 36F glossy polyester FDY plus 8 twists / S as the weft 3: 1 permutation, interweaving.

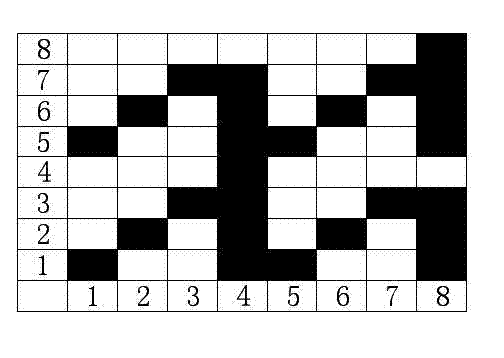

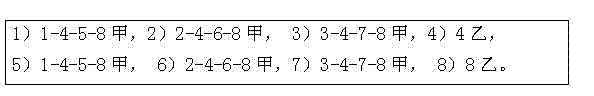

[0017] (2) Design 8*8 weft double weaving rules, such as figure 1 shown in figure 1 Among them, the longitudinal direction is the warp, and the horizontal direction is the weft. The numbers represent the position numbers of the warp and weft in each cycle, the black grid represents the warp floating point, and the white grid represents the weft floating point. When weaving the 1st, 2nd, 3rd, 5th, 6th, and 7th wefts, put in the first weft to weave the inner layer cloth, and lift all the surface warps 4 and 8 each time; When silk, drop into the second ki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com