Bidirectional gear oil pump or motor provided with full-hydraulic floating packingless bidirectional shaft sleeves

A two-way gear, no seal technology, used in liquid fuel engines, pumps, mechanical equipment, etc., can solve problems such as reducing the mechanical efficiency of the gear oil pump (motor mechanical efficiency, not conforming to the design concept of energy saving and environmental protection, insufficient hydraulic thrust, etc., to eliminate the need for seals. Structure, unbalance torque reduction, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

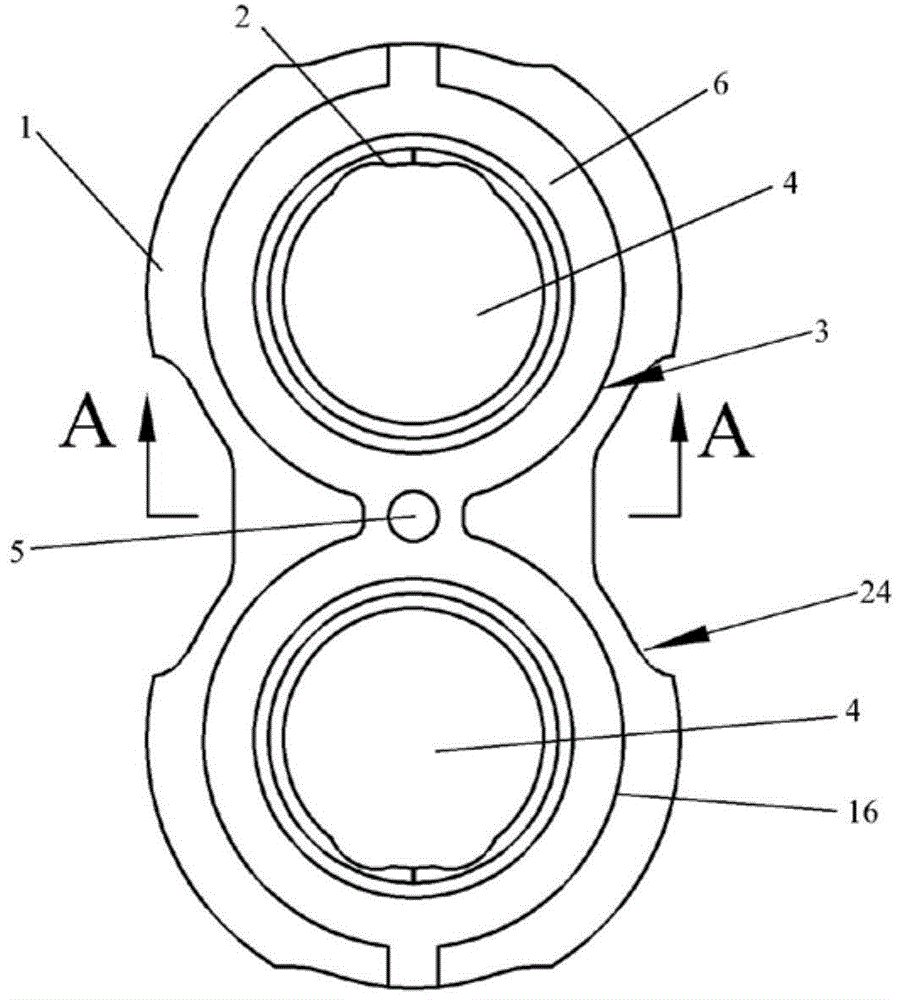

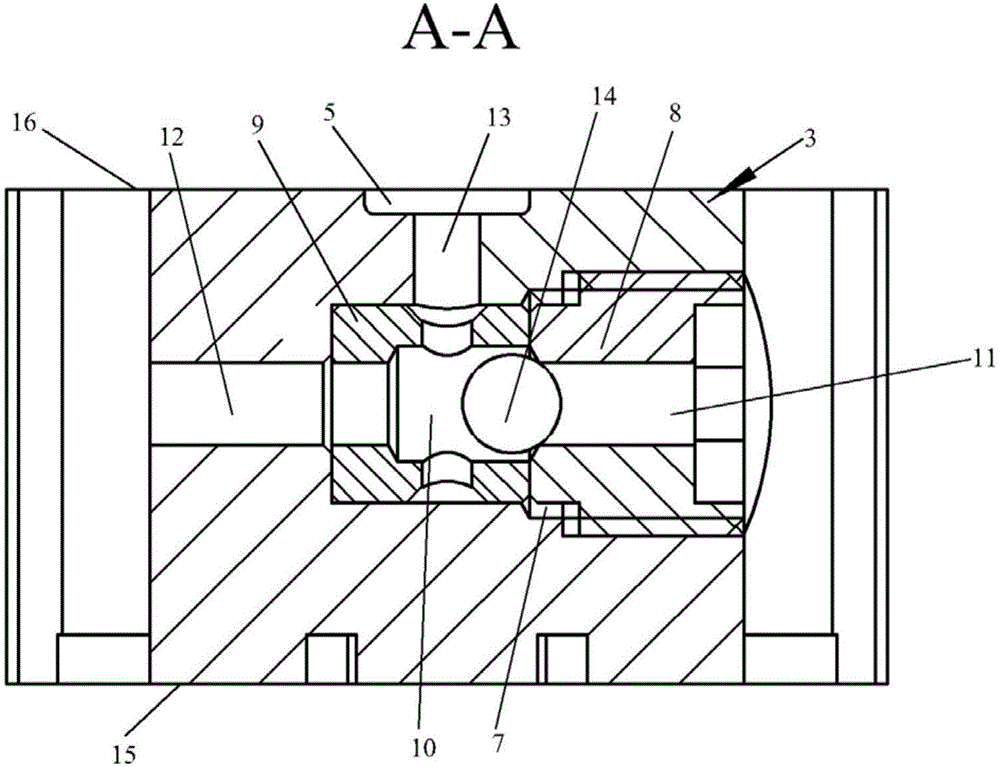

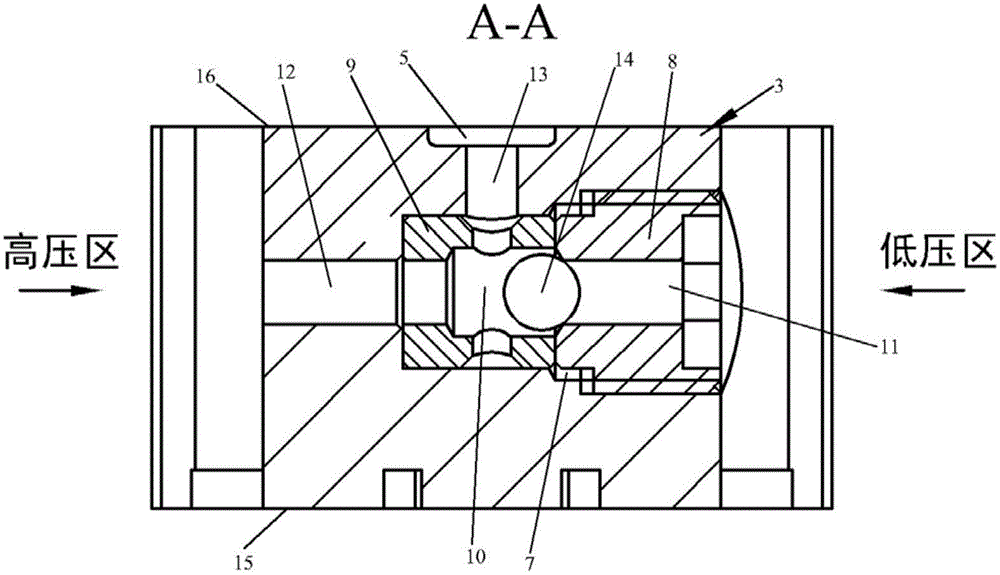

[0022] see Figure 7 , a bidirectional gear oil pump or motor with full hydraulic floating non-sealed bidirectional bushing, including a pump body 17, a gear shaft, a gear, two bushings 24, a front end cover 20 and a rear end cover 21; the front end cover 20 and the rear end cover End cover 21 is respectively arranged on the both sides of described pump body 17; Described gear comprises a driving gear 18 and a driven gear 19, and described driving gear 18 is meshed with described driven gear 19; Described gear shaft comprises A driving gear shaft 22 and a driven gear shaft 23; one end of the driving gear shaft 22 is inserted in the inner cavity of the pump body 17, and the driving gear 18, the driven gear 19 and the driven gear shaft 23 are all Set in the inner cavity of the pump body 17; the driving gear 18 and the driven gear 19 are respectively sleeved on the driving gear shaft 22 and the driven gear shaft 23; the two bushings 24 are respectively set On both sides of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com