Full-hydraulic floating sealing-free bidirectional shaft sleeve

A sealless, two-way shaft technology, applied in the direction of machines/engines, rotary piston type/oscillating piston type pump components, pump elements, etc., can solve the problem of reducing gear oil pump (motor mechanical efficiency, not in line with energy Insufficient thrust and other problems can save the sealing structure, reduce unbalanced torque and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

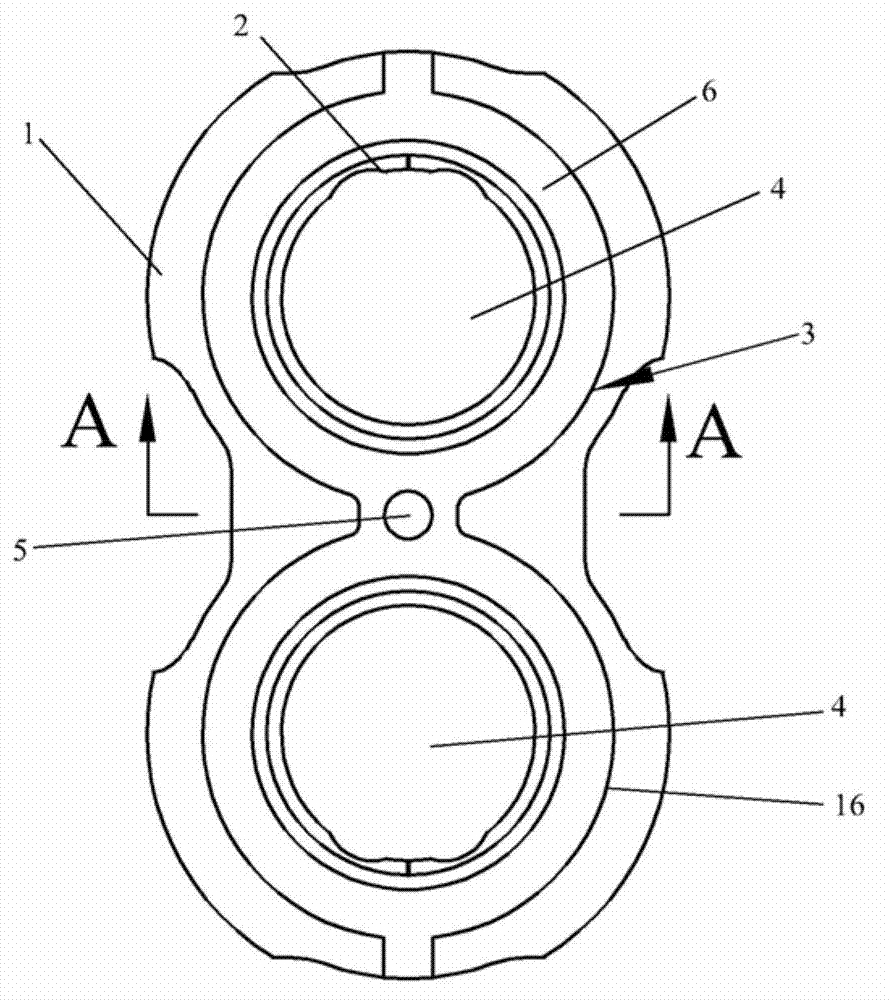

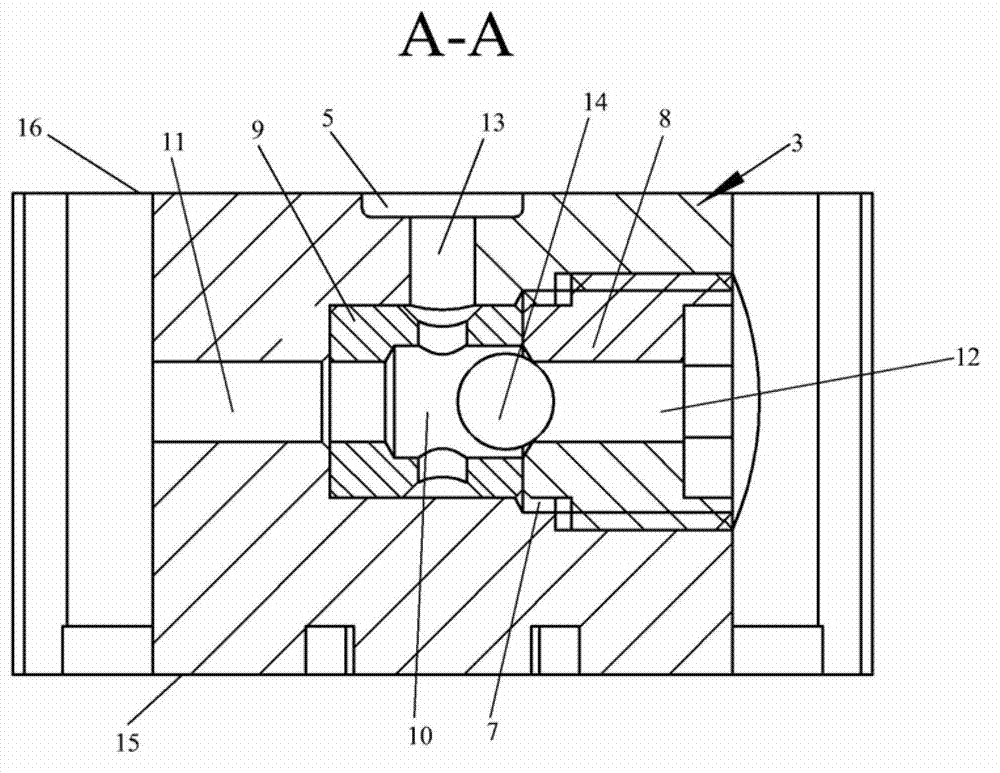

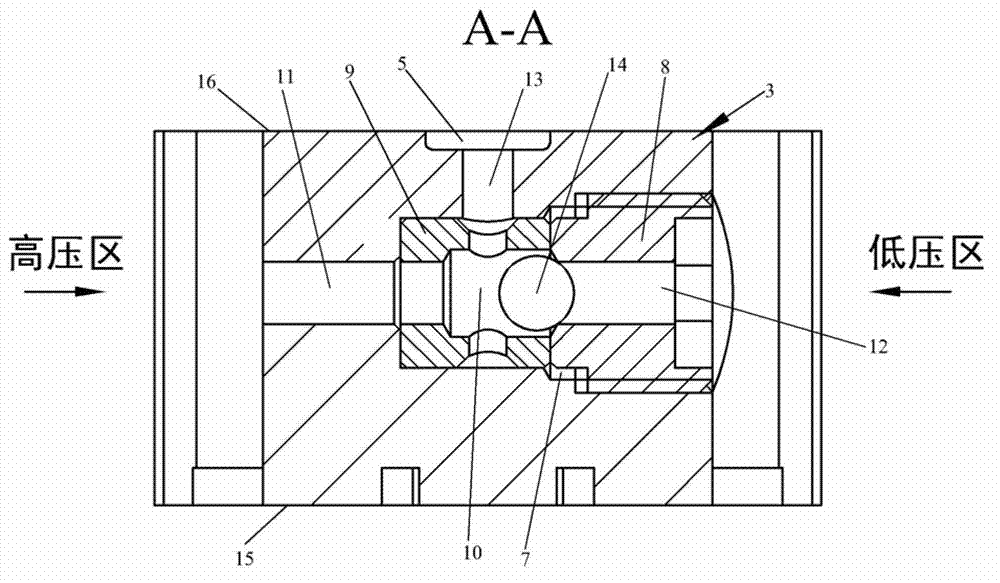

[0019] see attached picture figure 1 ~ attached Figure 4 , a fully hydraulic floating non-sealed two-way bushing, including an aluminum sleeve 1, a bushing 2 and a bushing body 3; the bushing body 3 is provided with two shaft bushings that penetrate the bushing along the thickness direction of the bushing body The through hole 4 of the body 3; on one side of the bushing body 3, an oil outlet 5 is provided between the two through holes 4; the side of the bushing body 3 with the oil outlet 5 is also provided There is an oil groove 6, and the oil groove 6 communicates with the oil outlet 5; a cavity 7 is arranged inside the sleeve body 3, and a valve seat 8 is arranged at the left end of the cavity 7, and the cavity 7 The right end is provided with a valve sleeve 9, and a valve cavity 10 is provided inside the valve sleeve 9; a first oil passage 11 is provided on the valve seat 8; a second oil passage 12 and a second oil passage 12 are provided on the sleeve body 3 Three oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com