Method for producing spring

A technology of manufacturing method and cooling method, applied in the field of spring manufacturing, can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, the manufacturing method of the spring in this embodiment will be described. In this embodiment, a case of manufacturing a stabilizer bar which is a type of spring will be described as an example. The stabilizer bar has a substantially linear portion and arm portions provided at both ends of the straight portion. When installing the stabilizer bar on the car, it is necessary to fix the arm parts at both ends to the left and right wheels, and fix the straight part to the vehicle body. In this way, when the stabilizer bar is installed on the vehicle body, the lateral roll of the vehicle body can be controlled to improve the driving stability of the vehicle when the vehicle is turning.

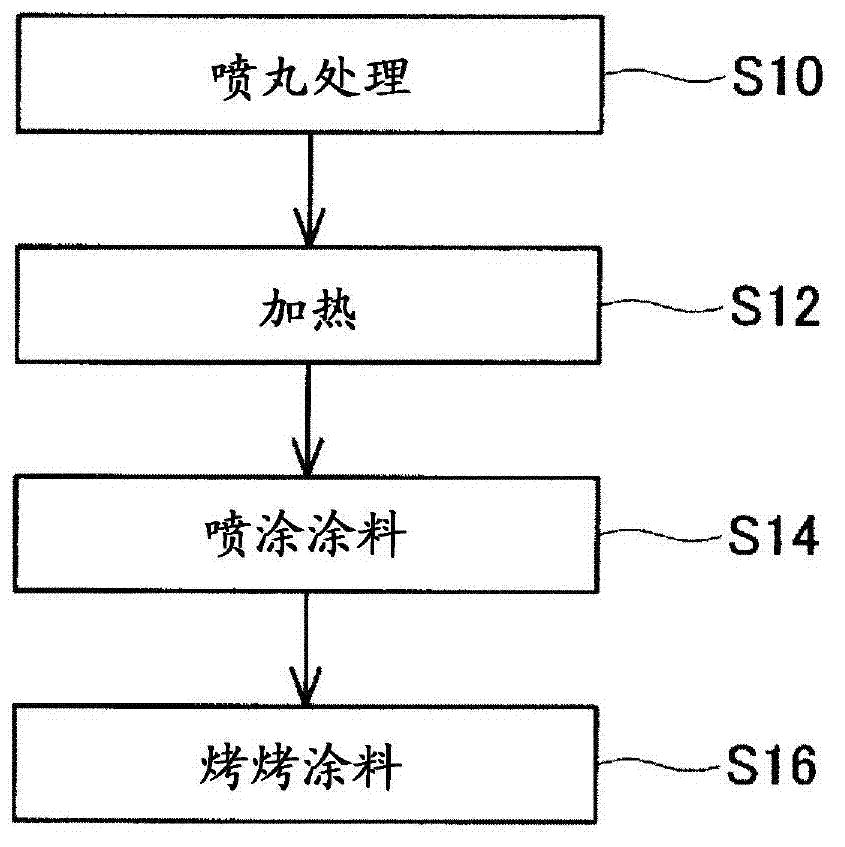

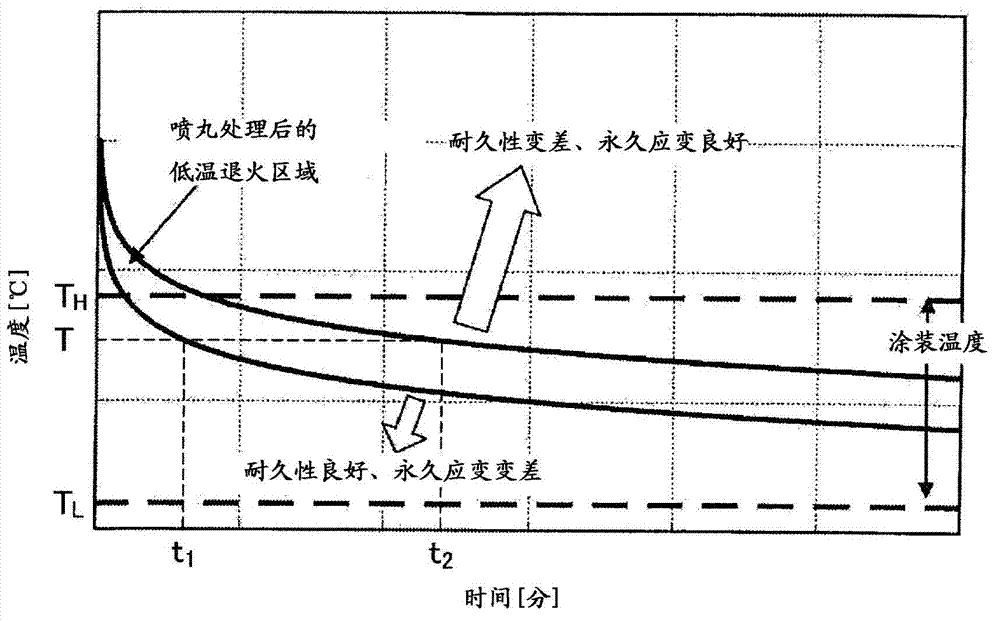

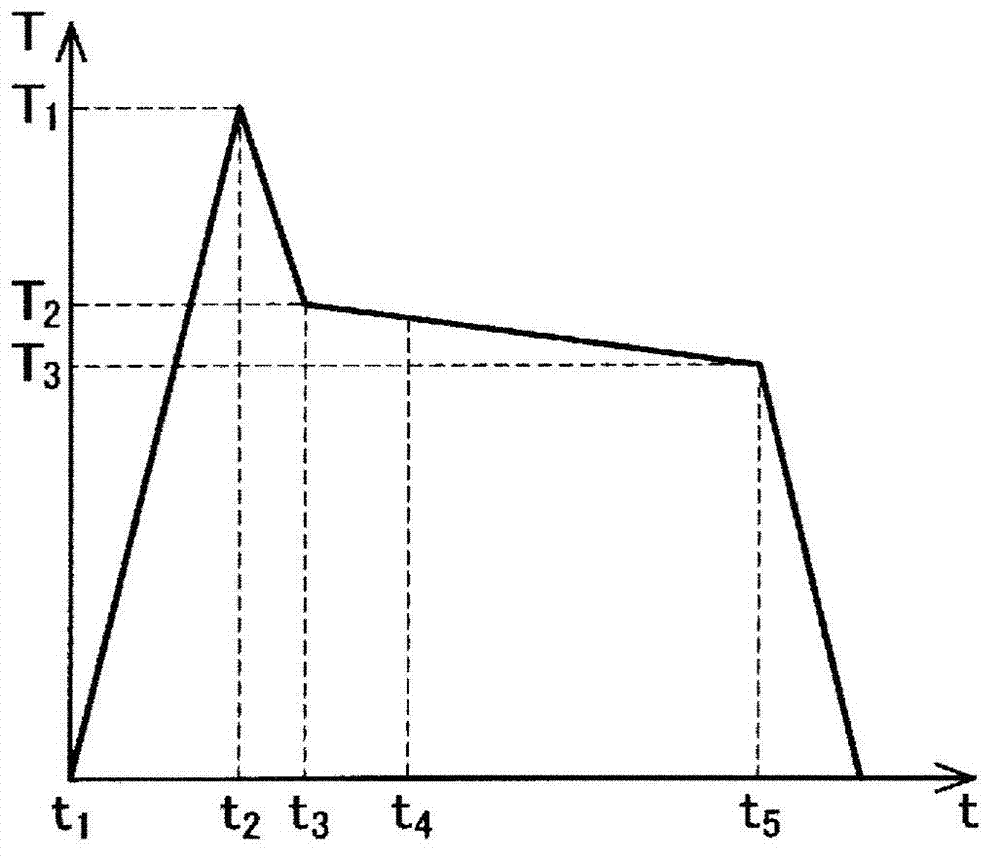

[0018] The manufacturing method of the stabilizer bar has the following steps: a forming step, firstly performing cold bending processing, heating bending processing, or hot bending processing on the steel material to form the shape of the stabilizer bar; Heat treatment; shot peeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com