Upward pushing and pressing expansion type in-barrel cleaning device

A cleaning device and expansion type technology, which is applied in the field of two-way push expansion type barrel cleaning device, can solve the problems of high production cost, unsafe, many people, etc., and achieve the effect of saving time and labor, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

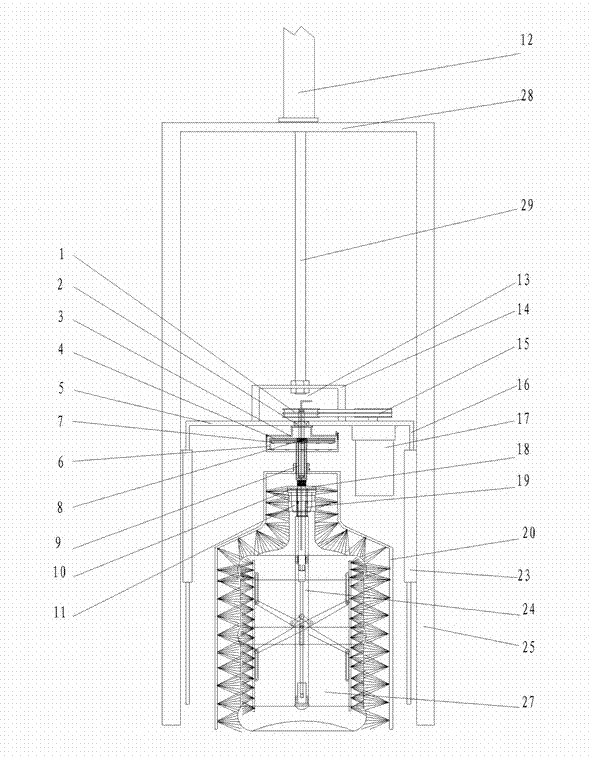

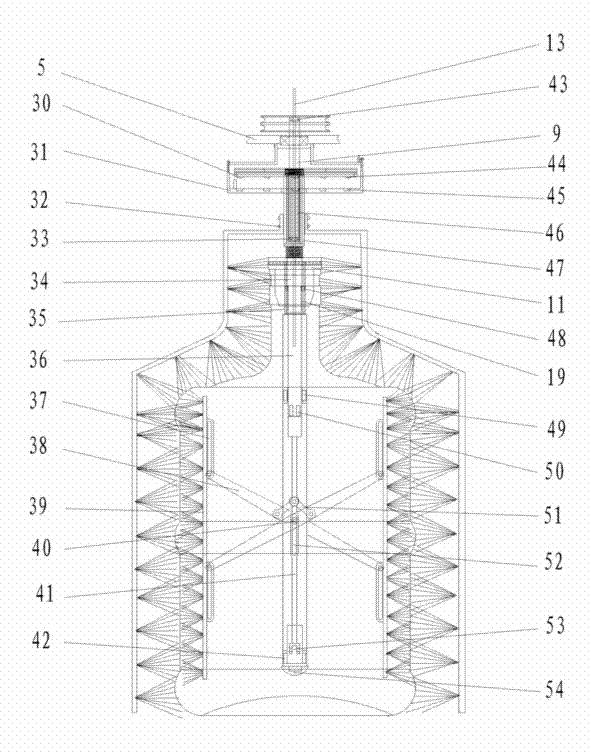

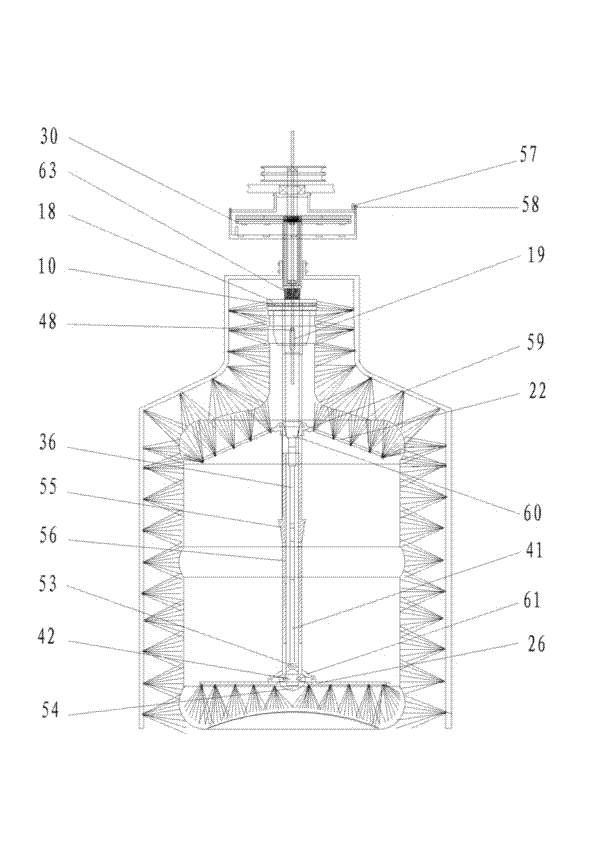

[0013] The push-up expansion barrel cleaner is characterized by: the cylinder (12) fixed on the cylinder platform (28) pushes the cylinder shaft (29) downward, and the connecting frame (14) connected to the cylinder shaft (29) Walking down at the same time, at this time, the connecting platform (4) runs downward along the guide tube (23) fixed on the leg (25) under the action of the guide shaft (16), and the brush rod (24) enters the bucket (27), when the brush holder (18) presses the mouth of the bucket, the driving shaft (9) drives the central push rod (36) to continue to walk downwards. At this time, the support rod fixed on the lower push rod (41) pushes and pulls The sheet (51) pushes out the brush holder stay (38) connected to it to both sides under the action of the lower push rod (41), and the bucket wall brush holder (39) on the brush holder stay (38) is close to the inner wall of the bucket and is fixed on the The bristles on the bucket wall brush seat (39) are in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com