Papermaking pulp board cutter

A board cutting machine and paper pulping technology, which is applied in metal processing and other directions, can solve the problems of pulper rotor damage, large size, and complexity, and achieve the effects of low manufacturing cost, improved work efficiency, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

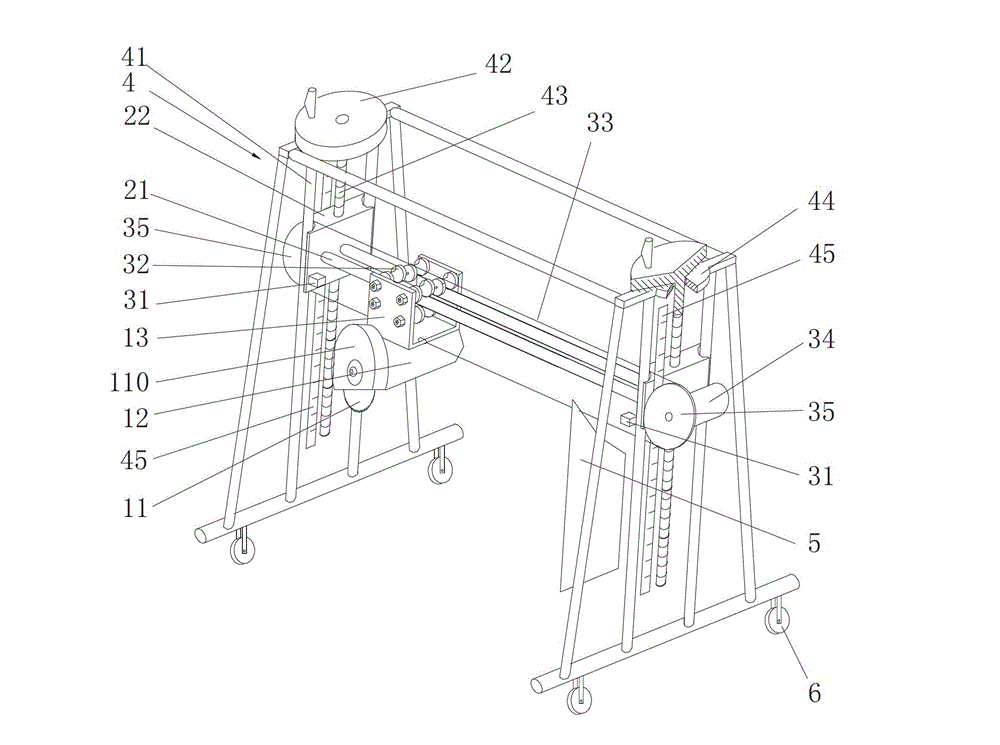

[0036] Such as figure 1 As shown, a papermaking pulp board cutting machine includes: a circular sawtooth sheet 11; a cutting motor 12, whose axis is used to fix the circular sawtooth sheet 11; a movable fixed frame 13, which is U-shaped, and the bottom is used for fixed cutting Motor 12; horizontal guide rail 21, is provided with two, and these two horizontal guide rails 21 are arranged in parallel; guide rail fixing frame 22, is used for being fixed on the two ends of horizontal guide rail 21; fixed frame 4, is used for fixing guide rail fixing frame 22; The horizontal reciprocating driving part is used to drive the movable fixed frame 13 to move back and forth along the horizontal guide rail 21 .

[0037] The horizontal reciprocating drive components include: reciprocating motor 34, which can rotate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap