Manual hole digging support pile prestress anchor cable anchoring structure and construction method of anchoring structure

A technology of prestressed anchor cable and artificial hole digging is applied in excavation, sheet pile wall, foundation structure engineering and other directions, which can solve the problems of complex construction process, waste of cost, ineffectiveness, etc., and achieve simple construction method and cost saving. , the effect of good anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

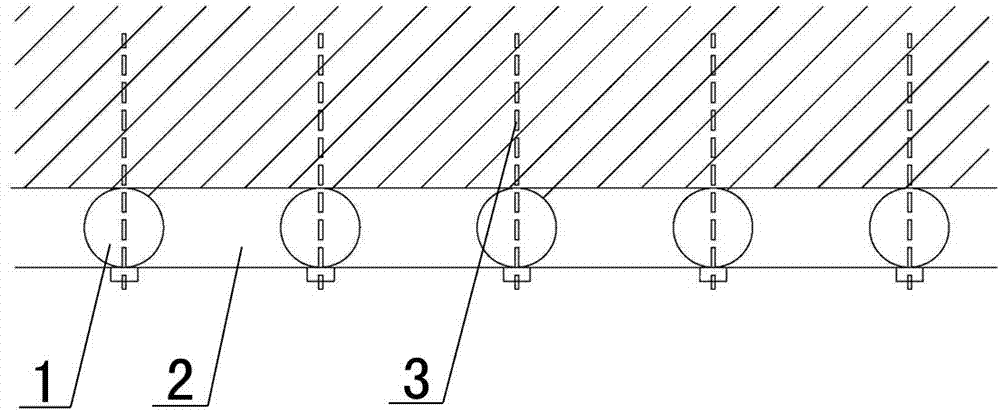

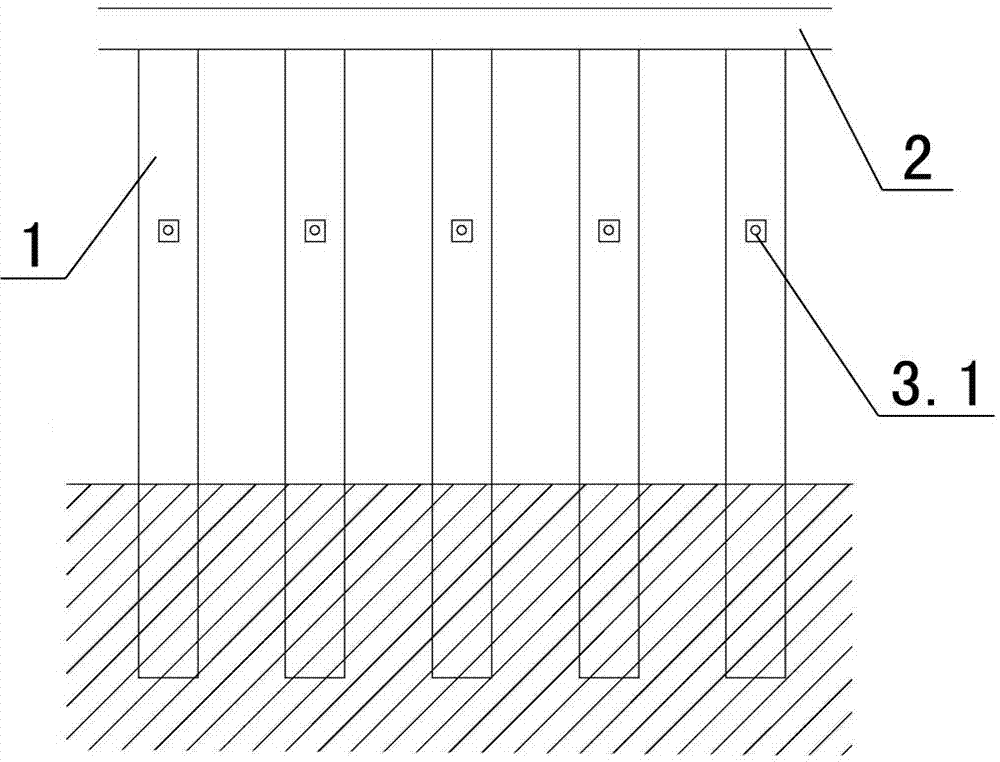

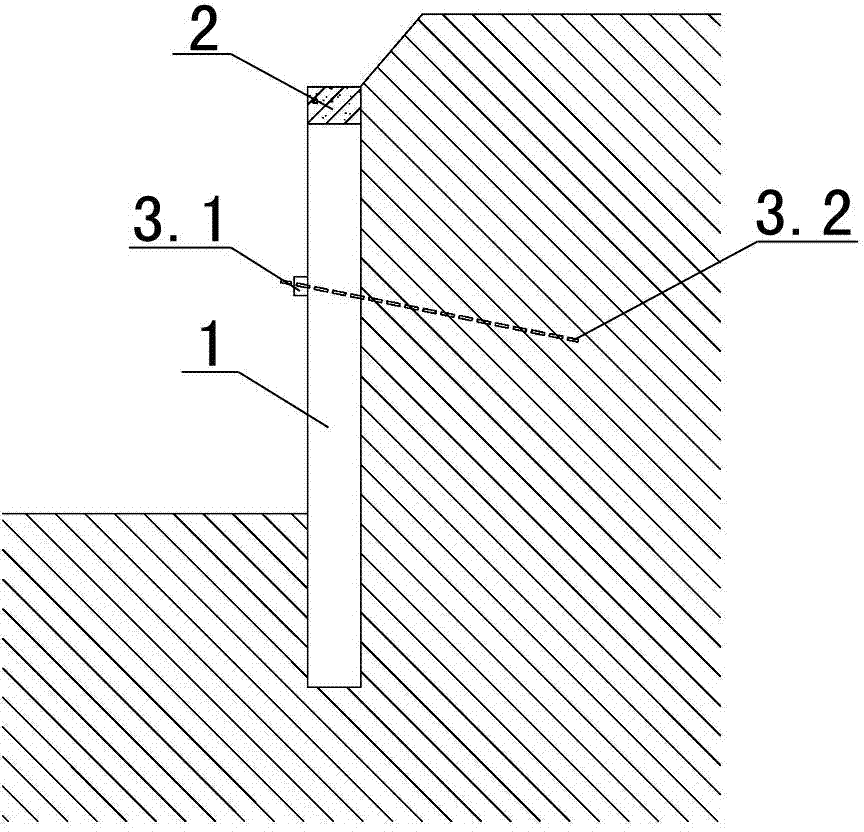

[0043] Examples see Figure 1-3 As shown, a prestressed anchor cable anchoring structure of artificial excavation support piles includes a circle of support piles 1 arranged along the inner side of the foundation pit, a connecting beam 2 arranged on the top of the adjacent support piles, and prestressed anchor cables 3. The prestressed anchor cable is divided into anchor head 3.1 and anchor body 3.2. The support pile 1 has anchor cable holes 4 at the same height in the foundation pit. The anchor body 3.2 passes through the anchor cable hole 4. The anchor body 3.2 The outer end is fixed by the anchor head 3.1, and the inner end of the anchor body 3.2 is anchored into the rock-soil body, and the anchor head 3.1 is located outside the support pile 1.

[0044] see Figure 9 As shown, the anchor head 3.1 is composed of anchorage 3.1.1, anchor pier 3.1.2 and anchor plate 3.1.3, and anchors the prestressed anchor cable on the outside of the support pile.

[0045] The diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com