Cryopump control apparatus, cryopump system, and method for monitoring cryopump

A control device, cryopump technology, applied in pump control, pump, axial flow pump, etc., can solve problems such as cryopump failure, adverse effects of manufacturing plans, increased downtime, etc., to achieve the effect of monitoring deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] First, an outline of an embodiment of the present invention will be described.

[0031] In order to effectively grasp the deterioration status of the cryopump, it is preferable to install a monitoring function or a self-diagnosis function in the cryopump system to monitor the operating state of the cryopump.

[0032] The inventors conceived that by monitoring the operation of the cryopump through regeneration processing performed as part of normal operation of the cryopump, it is possible to monitor the deterioration of the cryopump and accurately grasp the maintenance time.

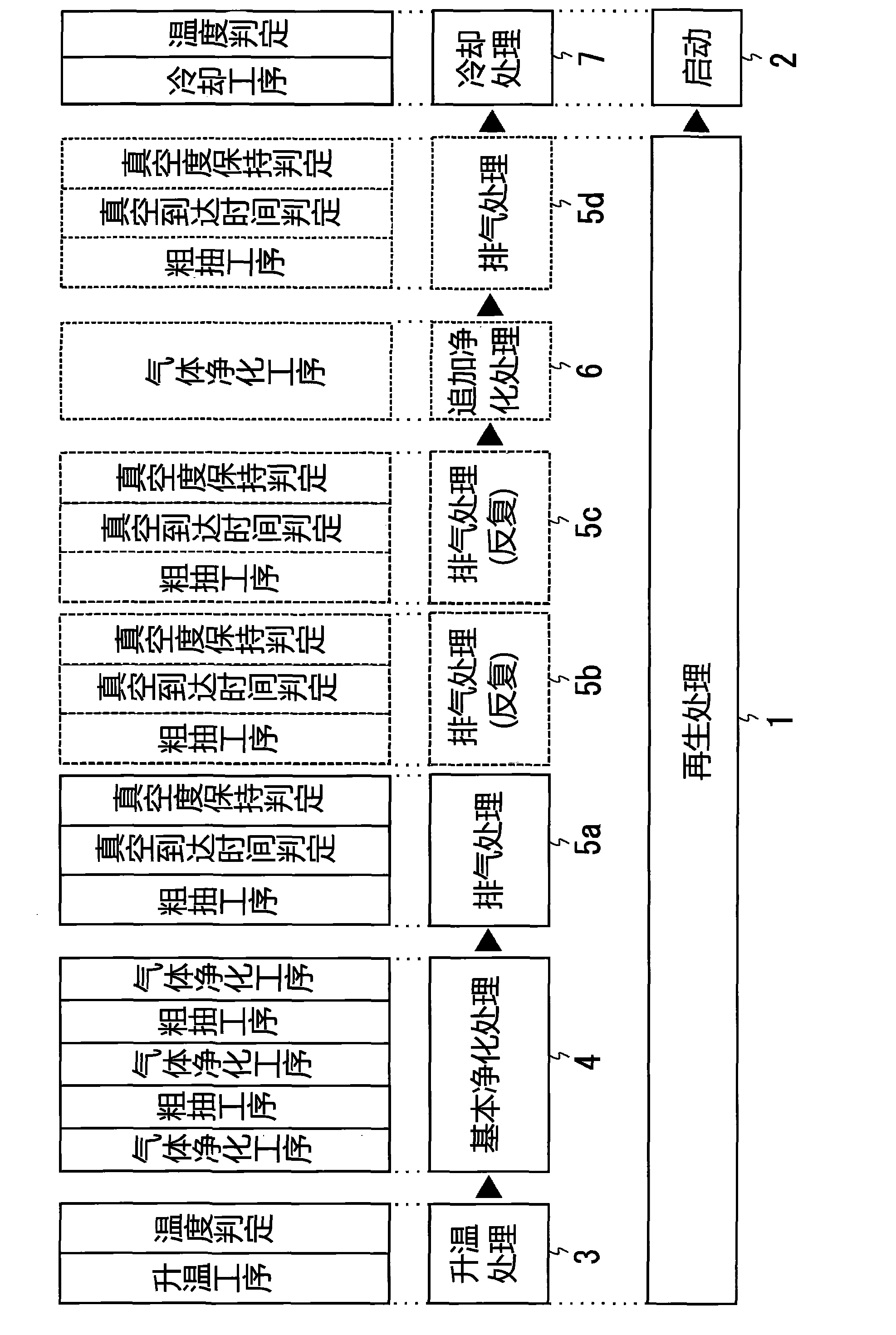

[0033] figure 1 Regeneration processing 1 and activation processing 2 of the cryopump according to the embodiment are shown.

[0034] Regeneration treatment 1 includes: temperature raising treatment 3, which vaporizes or liquefies the gas accumulated in the cryopump; purification treatment, which introduces purification gas such as nitrogen (hereinafter also referred to as is "purified gas"); Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com