Structure of composite gasket

A composite gasket and flat pad technology, applied in the field of mechanical parts, can solve the problems of high cost, troublesome manufacturing, unreliable connection, etc., and achieve the effect of low cost, simple manufacturing process and saving raw materials

Inactive Publication Date: 2012-12-19

丁丽凤

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the process of fastening mechanical parts, in order to prevent the nuts from loosening due to long-term use and the connection between the parts is not reliable, generally flat washers and spring washers are used in conjunction with each other. However, flat washers and The spring washers are all independent parts, which are not only cumbersome to manufacture, but also have the disadvantages of waste of materials and high cost due to their independent structures

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

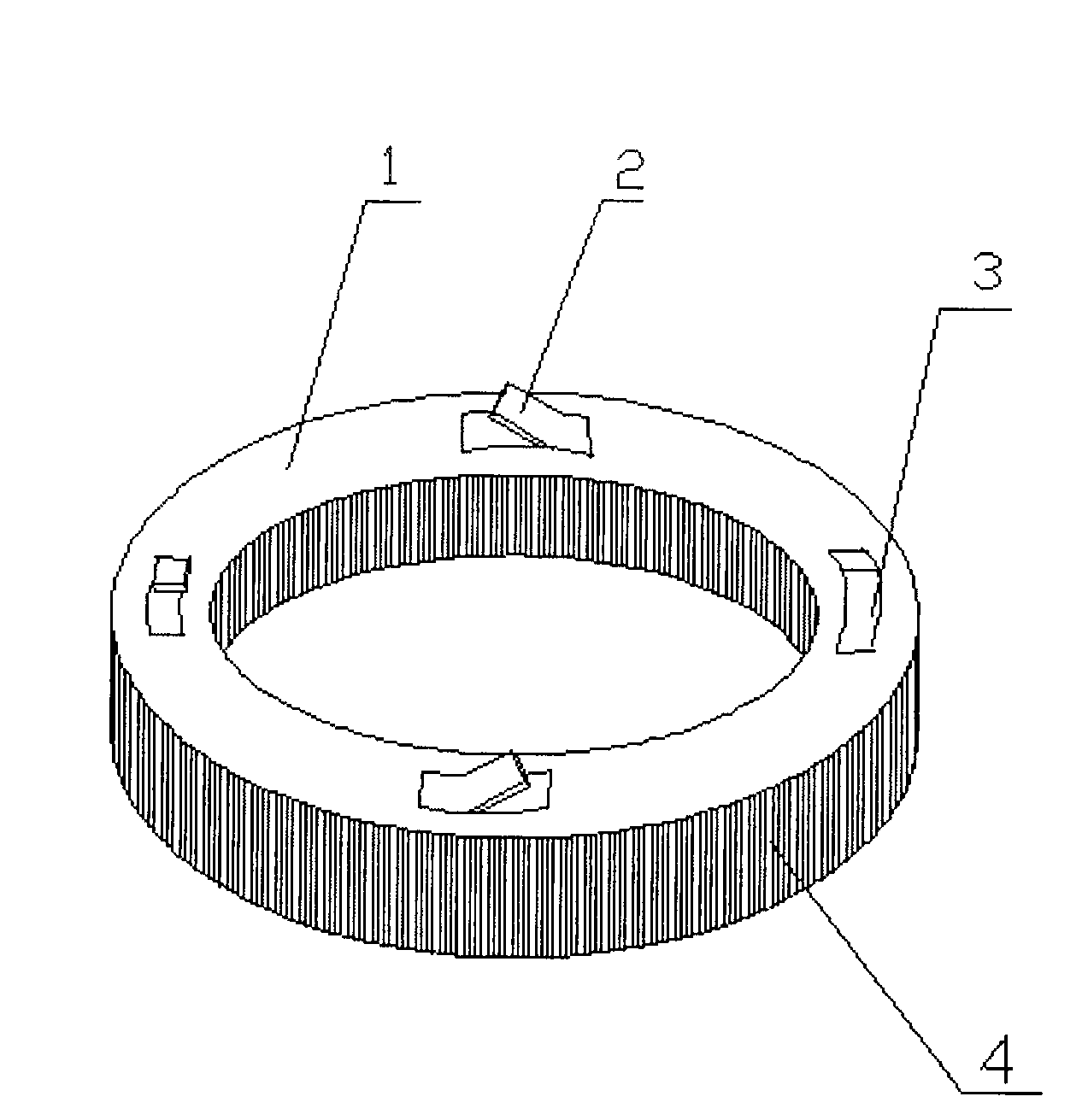

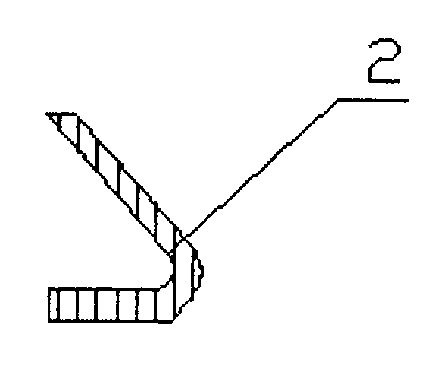

[0010] The composite washer has a flat pad surface 1 and a spring clip 2 made by a stamping process. There is a through hole 3 on the flat pad surface 1, and a spring clip 2 on the through hole 3. The spring clip 2 is symmetrically embedded in the long Waist-shaped through hole 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a structure of a composite gasket, which consists of a flat gasket surface, spring clips and through holes. The composite gasket is provided with the flat gasket surface and the spring clips, which are made by adopting a stamping process; the through holes are arranged on the upper surface of the flat gasket surface; the spring clips are arranged on the upper surfaces of the through holes; and the spring clips are positively and negatively symmetrically embedded in the long waist-shaped through holes. Under the squeezing action of nuts, constant elastic forces can be generated by the spring clips, and thus, when the spring clips are positively and negatively symmetrically embedded in the long waist-shaped through holes and the directions of retardation forces of the spring clips are opposite to the loosening directions of the nuts, double functions of a flat gasket and a spring gasket can be implemented. Meanwhile, the spring clips are simple structures, and thus, the structure of the composite gasket has the advantages of simple manufacturing process, raw material saving and low cost.

Description

technical field [0001] The invention relates to a gasket structure, in particular to a composite gasket structure, and belongs to the technical field of mechanical parts. Background technique [0002] At present, in the process of fastening mechanical parts, in order to prevent the nuts from loosening due to long-term use and the connection between parts is unreliable, flat washers and spring washers are generally used in combination. However, flat washers and spring washers are used together. The spring washers are all independent parts, which are not only cumbersome to manufacture, but also have the disadvantages of waste of materials and high cost due to their independent structures. Contents of the invention [0003] The object of the present invention is to provide a structure of a composite washer, which has the dual functions of a flat washer surface ring and a spring washer, which not only has a simple manufacturing process, but also has the advantages of saving ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16B39/24

Inventor 丁丽凤

Owner 丁丽凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com