Continuous casting mold, method for adjusting taper of continuous casting mold, and continuous casting method

A casting mold and linkage technology, which is applied in the taper adjustment of continuous casting molds and in the field of continuous casting casting molds, can solve problems such as increased maintenance costs, complicated control, and harsh setting environments, and achieves the effect of a simple drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

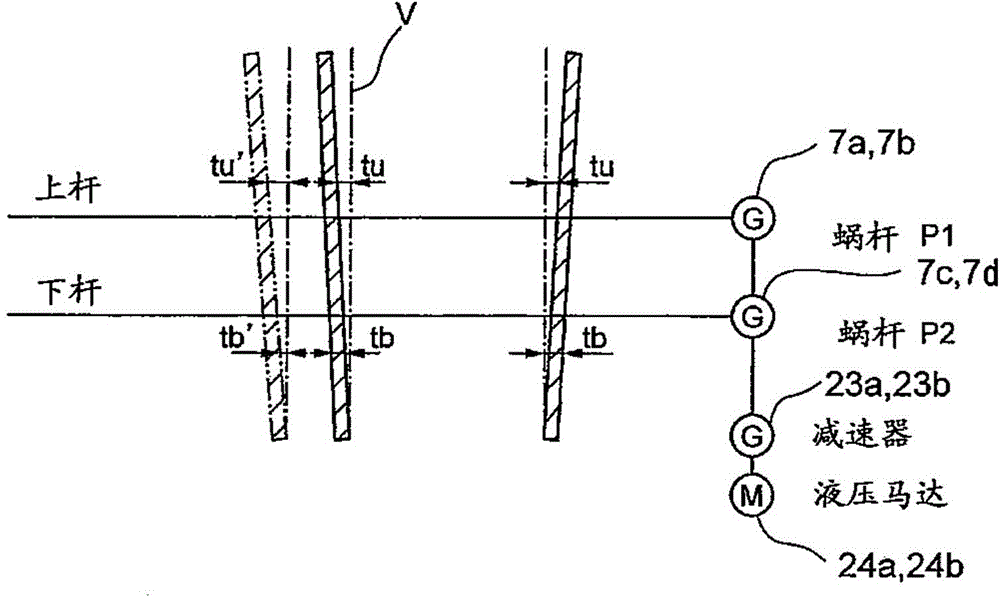

[0045] The pitch of the upper worm on the long side of the movable mold (equal to the lead because it is one thread) is 12.038 mm, and the pitch of the lower worm is 12.000 mm. The optimum taper shape shown in 1 (expressed as long-side taper = difference between upper and lower ends). In addition, the distance between the mold long pieces is set to be slightly larger than the thickness of the slab.

[0046] [Table 1]

[0047] Slab Thickness

Long side taper (difference between upper and lower ends)

220mm thick

2.00mm

235mm thick

2.15mm

260mm thick

2.48mm

300mm thick

3.00mm

[0048] In the comparative example where the taper of the long side was fixed, the taper of the long side was fixed at 2.3 mm (upper end of the short side - short lower edge). In this case, the long-side taper at a thickness of 220 mm is also 2.3 mm.

[0049] Table 2 shows comparative examples in which the long-side taper is fixed.

[0050]...

Embodiment 2

[0053] The casting mold of the example of the present invention and the casting mold of the comparative example were assembled in the continuous casting machine, and the actual machine was used to compare to what extent the maximum casting speed could be increased. Table 3 shows the specifications of the continuous casting machine used. The casting mold of the example of this invention was assembled in the continuous casting machine A, and the casting mold of the comparative example was assembled in the continuous casting machine B.

[0054] [table 3]

[0055]

[0056] Table 4 and Table 5 show the results of the experiments. As evaluation items, it was judged whether or not work was possible in consideration of powder consumption, presence or absence of sand adhering, drawing resistance, and the like. Mark ○ if it can work, and × if it cannot work.

[0057] [Table 4]

[0058] Continuous casting machine A (example of the present invention)

[0059]

[0060]

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com